Linear and planar motor coil winding apparatus and method

A technology of planar motors and crimping devices, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of single-shaped coils in winding molds, low coil winding efficiency, and low application range, and achieve winding Accurate and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

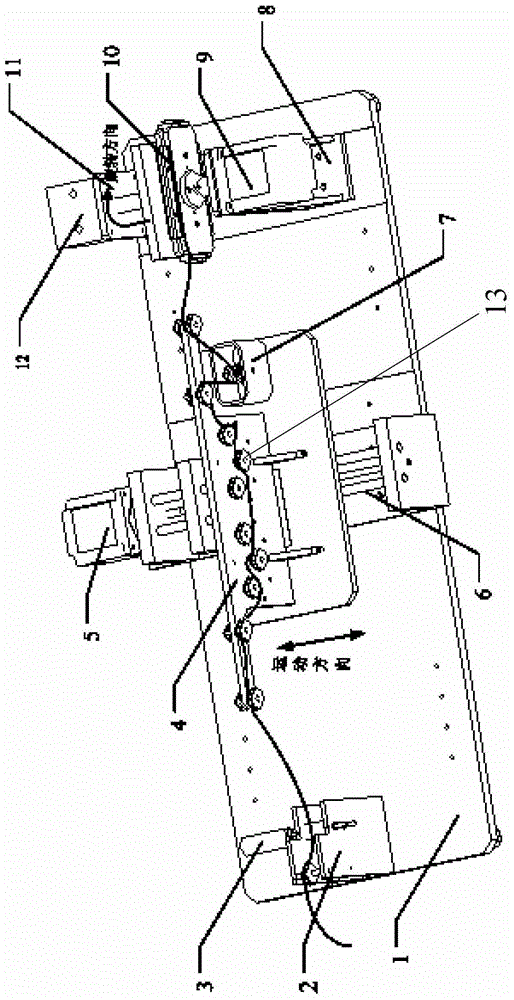

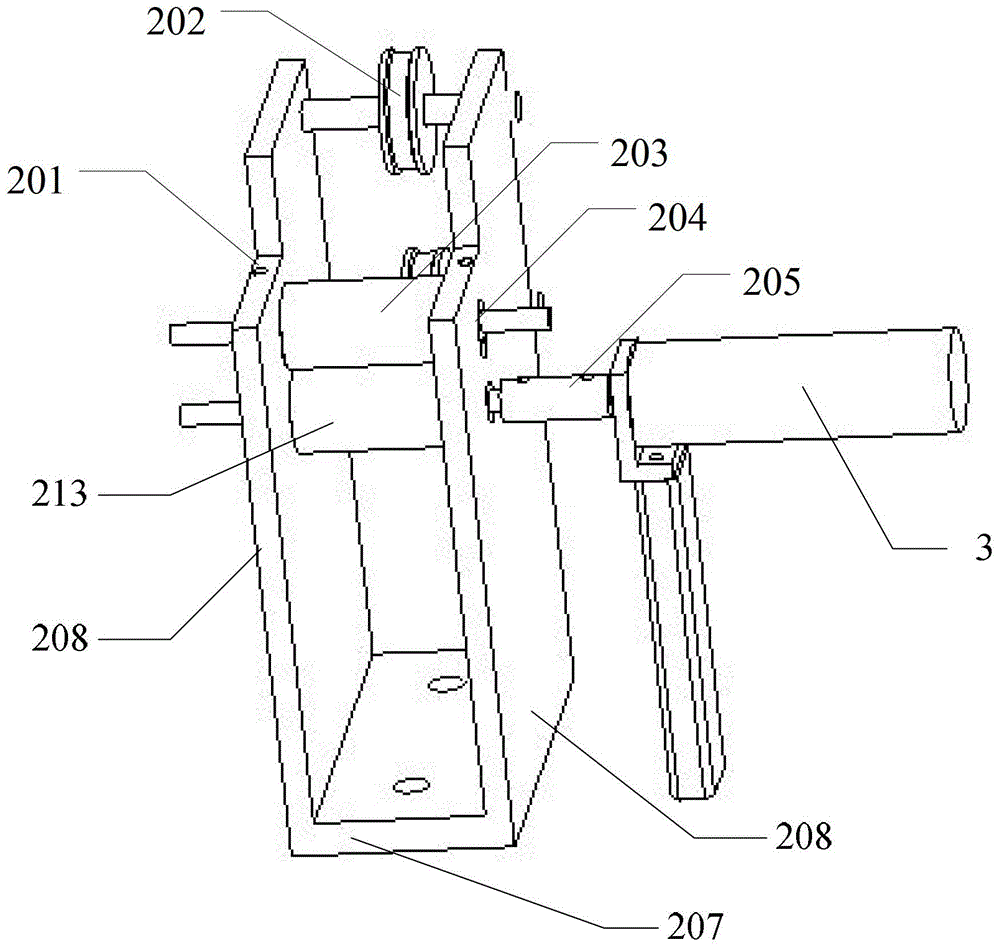

[0058] Please refer to figure 1 , This embodiment provides a linear and planar motor coil winding device for winding flat or round enameled wire, including a wire crimping device, a wire passing mechanism and a winding mechanism, the wire passing mechanism It includes a wire passing panel 4 and a wire passing wheel array 13. The winding mechanism includes a winding die 10 and a winding motor 9. The wire passing wheel array 13 is arranged on the surface of the wire passing panel 4, and the enameled wire passes The wire pressing device is transferred to the winding wheel array 13, the enameled wire is transferred to the winding die 10 through the 13 columns of the winding wheel array, and the winding motor 9 drives the winding die 10 to rotate , The enameled wire is wound on the winding die 10 through the rotation of the winding die 10.

[0059] Through the setting of the wire pressing device and the wire passing mechanism, the present invention can provide pre-tightening force for...

Embodiment 2

[0087] Please refer to Figure 1 to Figure 6 This embodiment provides another linear and planar motor coil winding method. The linear and planar motor coil winding device provided in Example 1 is used to wind the flat enameled wire. When the enameled wire is transferred to the winding The following steps are included in the line mold:

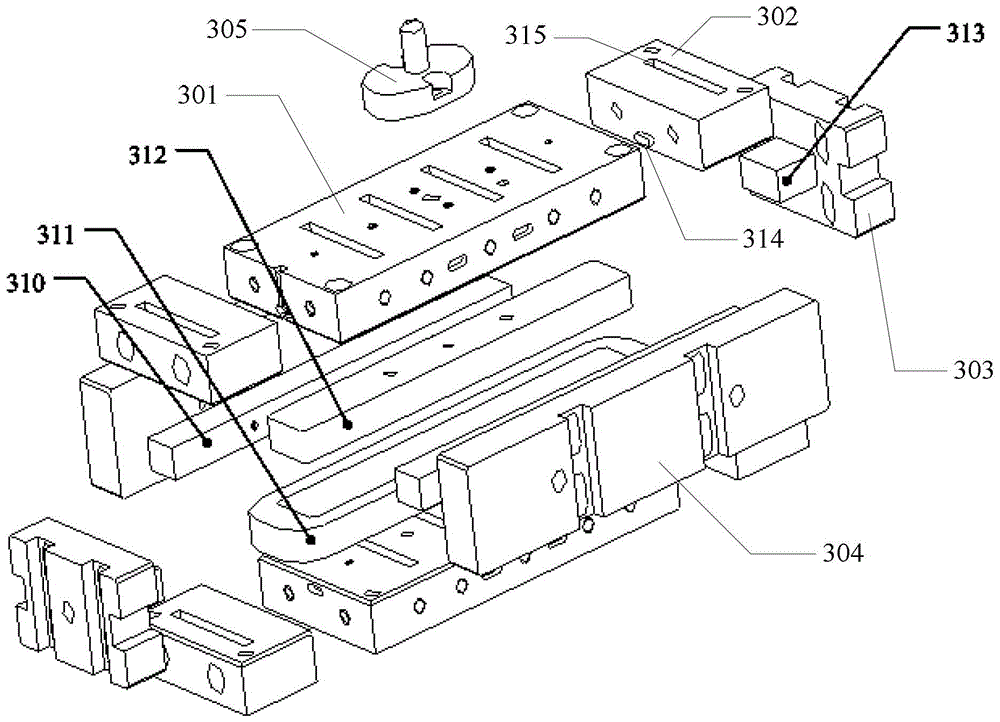

[0088] S201: Place the enameled wire close to the side surface of one of the winding substrates 301, wind the first turn of the coil around the winding post 312, and then pass the wire end through the wire outlet groove 309 to the winding screw 306 Connect; that is, the thread is wound on the winding screw 306;

[0089] S202: By starting the winding motor 9 to make the winding die 10 rotate, the enameled wire transferred to the winding die 10 is wound on the winding post 312, and during the winding process, always The coil wound by the latter turn is placed on the outer side of the former coil perpendicular to the winding surface of the bobbin 312...

Embodiment 3

[0097] The difference between this embodiment and embodiment 1 and embodiment 2 is only that the mechanism of winding die 10 is slightly different, please refer to Figure 7 versus Figure 8 The winding die includes two winding substrates 501. The sides of the two winding substrates 501 are provided with a protrusion 502 and a slot 503, respectively. The two winding substrates 501 The parts 502 are matched and inserted into the slots 503 of each other to realize the connection, and are locked by fastening screws (not shown). The two convex parts 502 are combined to form a winding post for winding, and the winding substrate 501 is provided There are outlet slots (not shown) for the enameled wire to pass through and winding screws (not shown) for fixing the end of the enameled wire. In addition, the functions, shapes and coil winding methods of the components in Embodiments 1 and 2 are all applicable to this embodiment. The structure adopted in this embodiment is simpler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com