Cable winding tool

A cable winding and cable technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of high labor intensity, achieve the effects of reducing labor intensity, improving versatility, and realizing automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

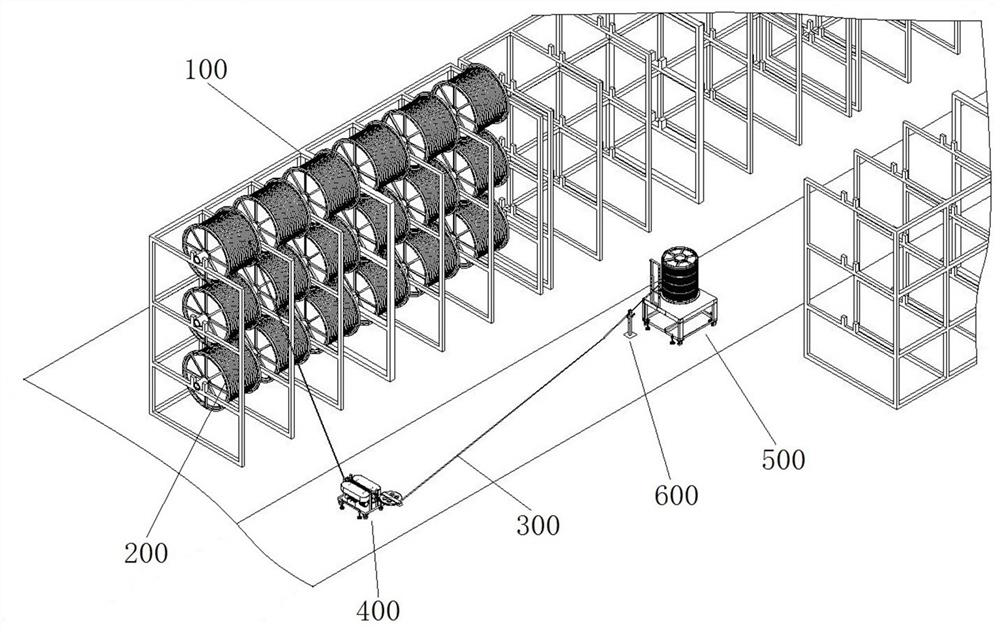

[0076] Such as Figure 1 to Figure 14 As shown, when the cable winding tool is in use, the cable 300 on the large cable reel 200 on the shelf 100 is dragged down, cut and wound at a fixed length.

[0077] The cable winding tool includes a cable dragging device 400 and a cable winding device 500 sequentially arranged along the conveying direction of the cable 300, and also includes a length measuring device 600 between them. The cable dragging device 400 is used to drag the cable 300 from the large cable reel 200, the length measuring device 600 is used to measure the length of the cable 300, and the cable winding device 500 is used to wind the cable 300. The cable 300 is wound onto the reel of the cable winding device 500 .

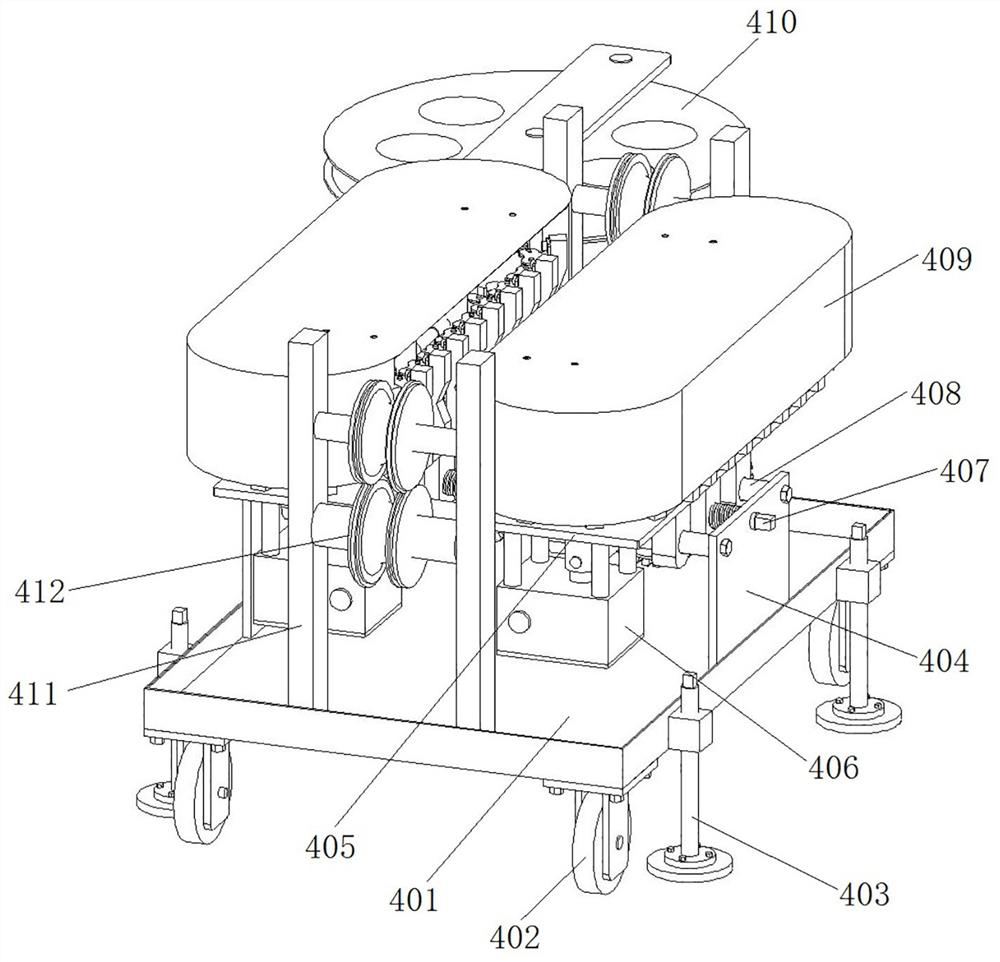

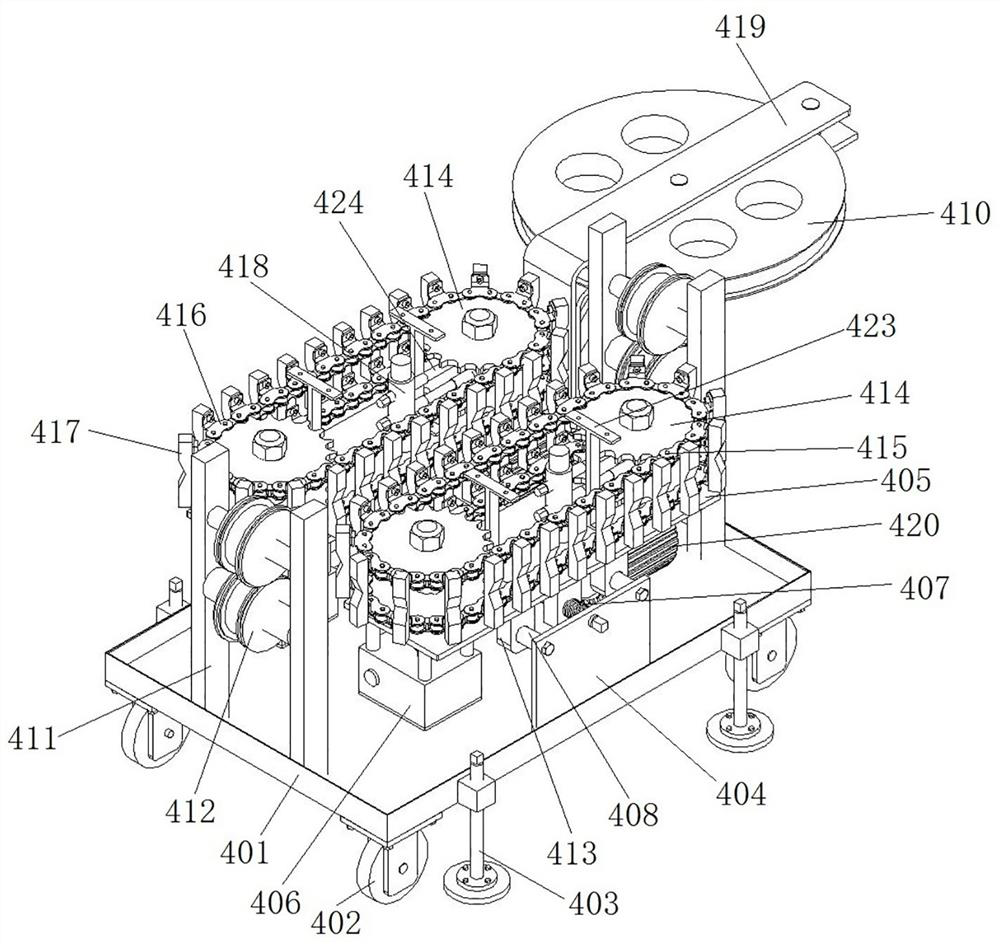

[0078] The structure of the cable dragging device 400 is as Figure 2 to Figure 10 As shown, the cable dragging device 400 is used to drag the cable 300. Since the large cable reel 200 on the shelf 100 is heavy in weight, it requires a large dragging fo...

specific Embodiment 2

[0102] The difference from Embodiment 1 lies in the cable winding device. Such as Figure 15 to Figure 18 As shown, the cable winding device 700 includes a frame 701, on which a motor, a friction clutch, a flange, a guide cylinder, etc. are installed, and its structure is consistent with that of the cable winding device in Embodiment 1, and will not be described in this embodiment. Let's go into more detail. A main support 702 is placed on the flange, and the structure of the main support 702 is as follows Figure 17As shown, the main support 702 includes a bottom support 7021. The bottom support 7021 includes two rings arranged coaxially and a support rod connecting the two rings. A cone 7022 is fixed in the middle of the bottom support 7021. The cone 7022 is narrow at the top and wide at the bottom. The structure has a hole in the middle for the guide cylinder to penetrate to radially position the cone 7022. The top of the cone 7022 is fixed with a square rod 7023, the sq...

specific Embodiment 3

[0109] In Embodiment 1, the supporting rod in the winding reel in the cable winding device realizes the winding of multiple cables of different specifications and types. In this embodiment, the support rods in the winding reel can be canceled, and the reel only winds cables of one specification and type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com