Fluid-driven self-adaption pipeline crawler

A pipeline crawler, fluid-driven technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of limited walking distance, complicated design and manufacture of robot walking mechanism, unstable walking speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

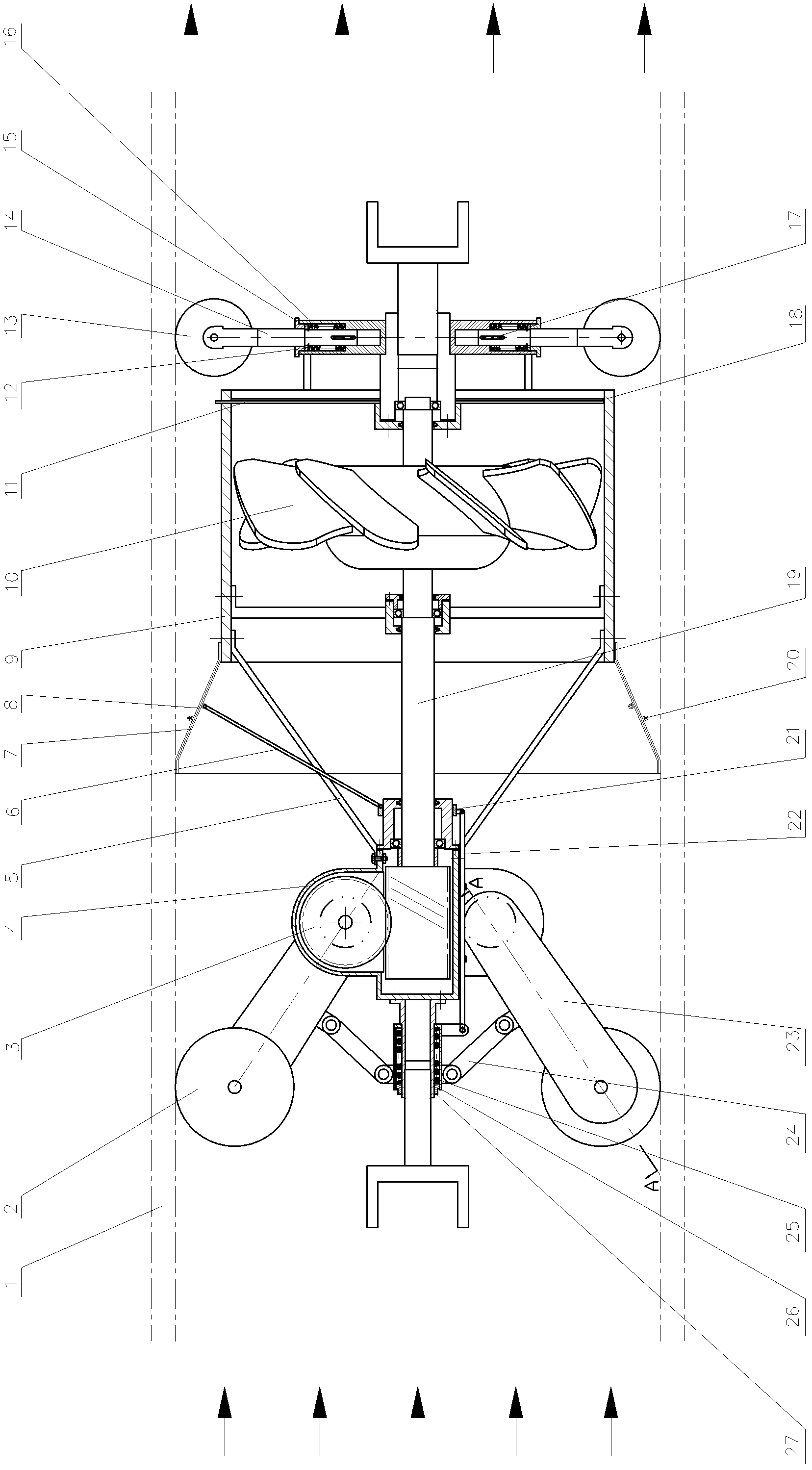

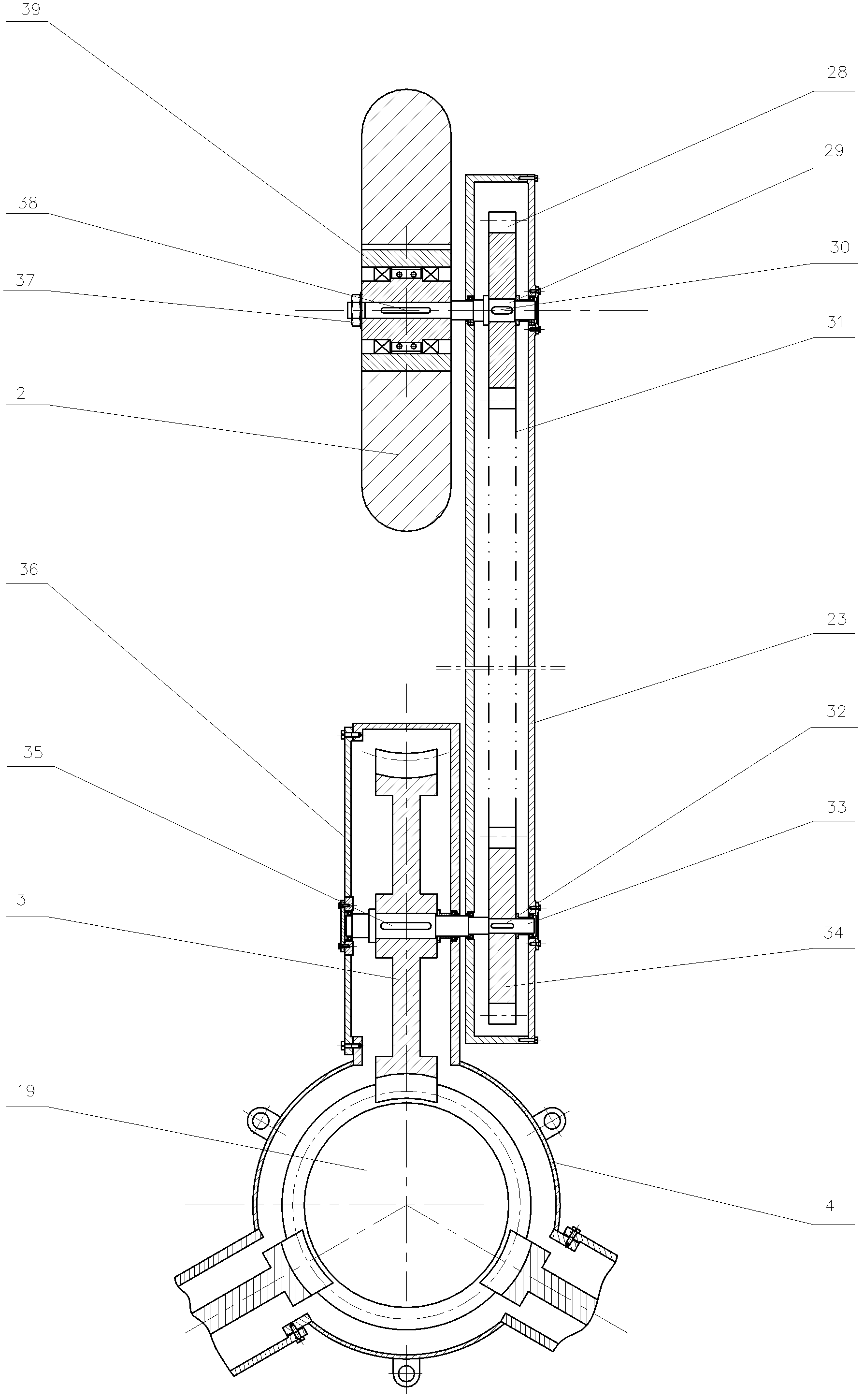

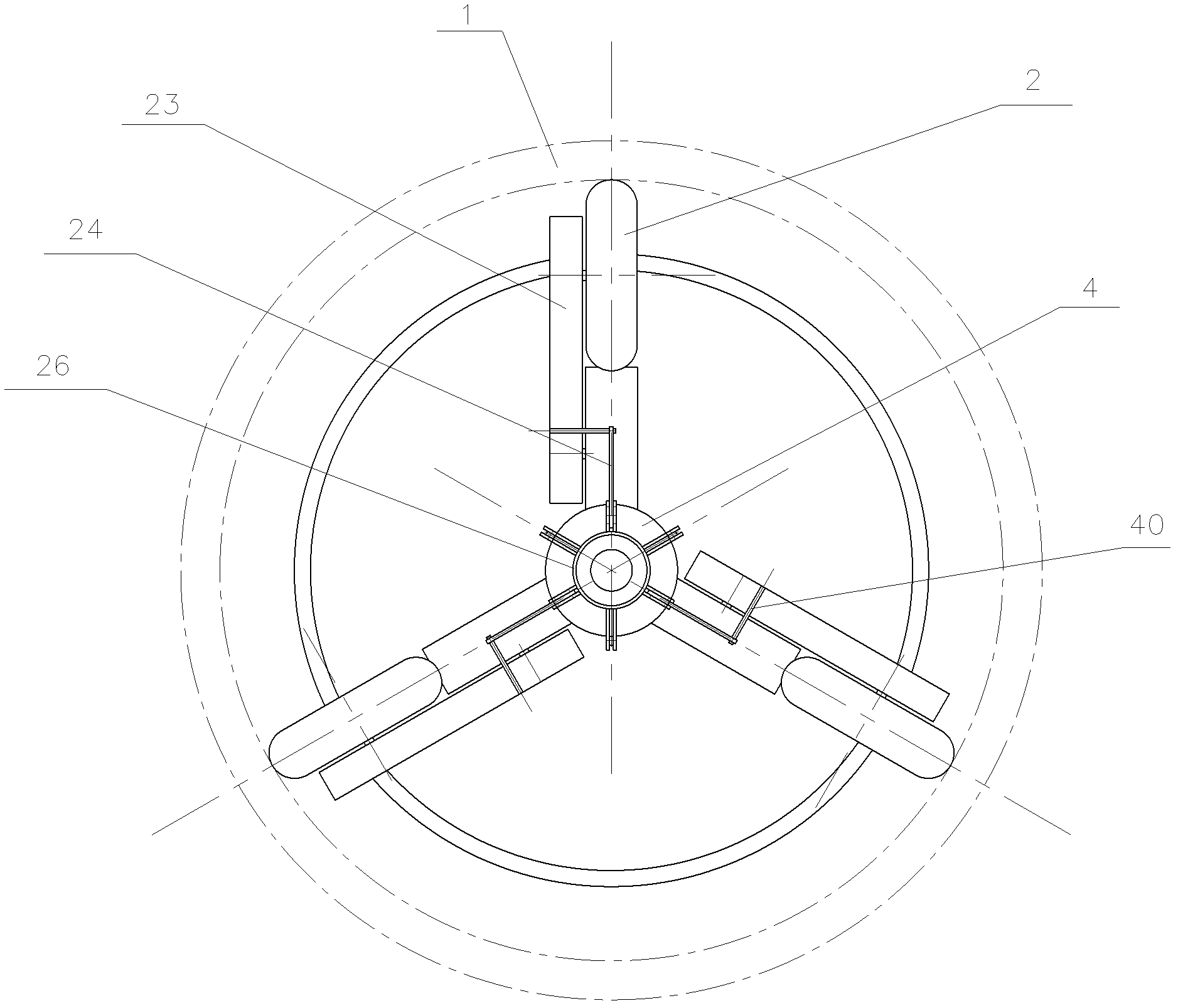

[0023] a. Driving process

[0024] refer to Figure 1~3 , under the working condition of the crawler in the fluid conveying pipeline, the fluid flows in the direction shown by the arrow in the figure. The fluid flows to the umbrella-shaped hydrofoil [8][7], changes direction and enters the guide tube [9], and the impeller [10] is installed in the guide tube, and the fluid flows to push the impeller [10] to rotate, and the impeller and the power shaft [19] is fixedly connected to make the power shaft rotate, and the rear end of the power shaft [19] is a worm, which rotates and drives three turbines [3] meshing with it to rotate, and the turbine drives the coaxial driving pulley [34] ] rotates, the driving pulley [34] transmits power to the driven pulley [28] by the synchronous belt [31], and transmits the power to the driving wheel [2] by the rotating shaft.

[0025] When the fluid flow speed increases, the fluid pressure difference on both sides of the crawler increases, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com