Pipeline leakage detection method based on pipeline pressure data

A technology for pipeline leakage and detection methods, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as pipeline modeling analysis, deviation, and difficulty in obtaining pipe section pressure data, and achieves overcoming complex operation and operation. Simple, predictable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

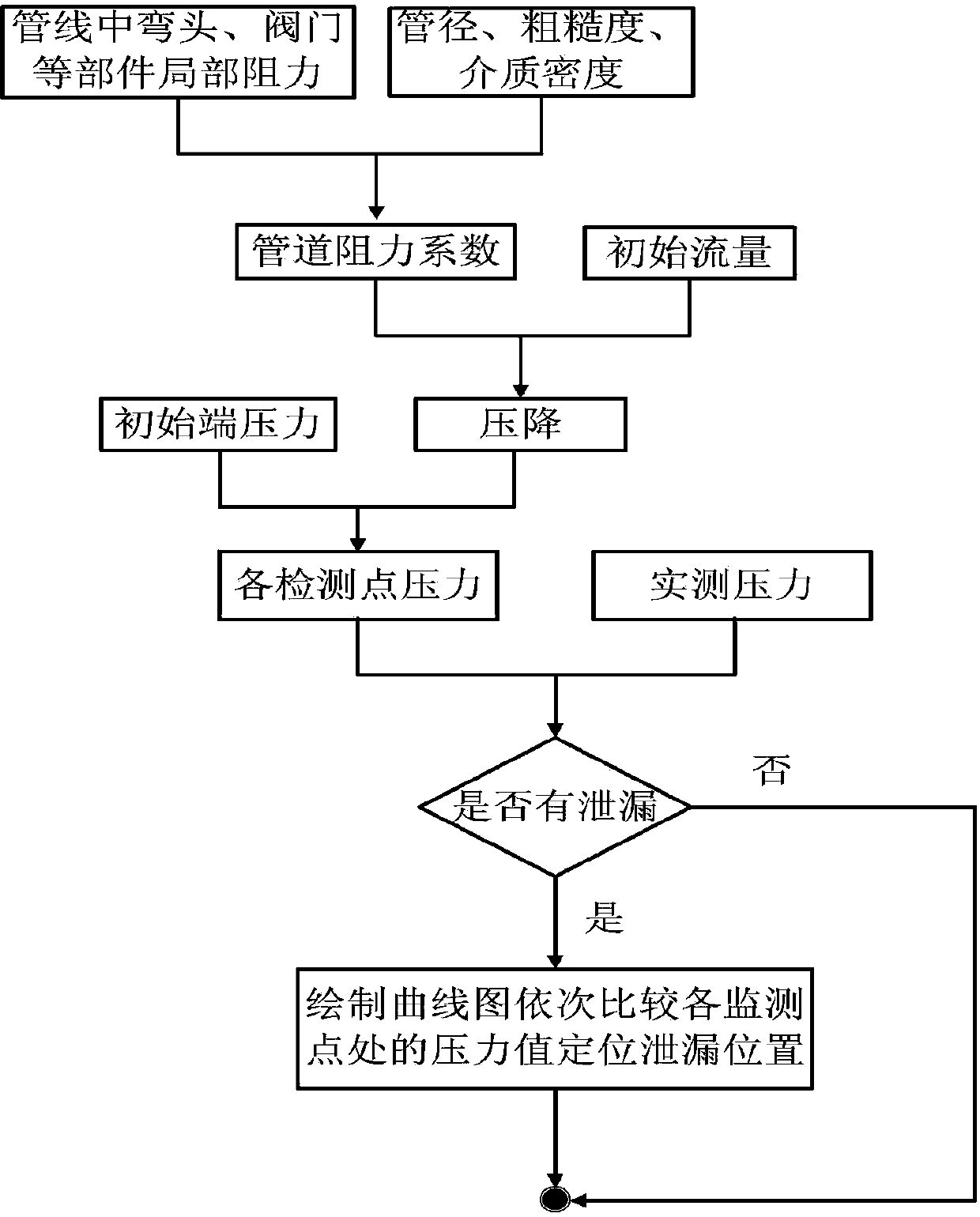

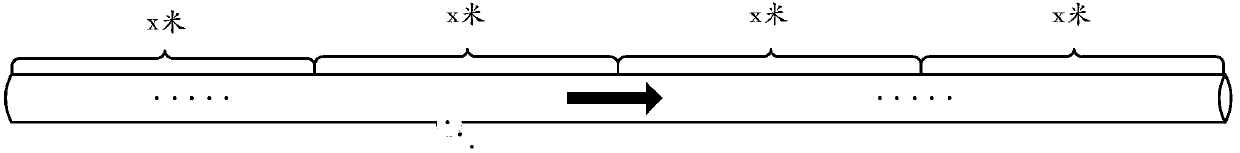

[0024] The flow of the whole algorithm is as follows figure 1 shown, assuming figure 2 It is a specific pipeline, and the conditions such as the diameter of the pipeline, the flow rate at the pipeline inlet, the pressure and the roughness of the inner wall of the pipeline are known. Assuming that the total length of the pipeline is 4x meters, the entire pipeline is divided into 4 parts by x meters, and the resistance of each part is the same , ignoring components such as elbows and valves in the pipeline, use the formula Calculate the resistance coefficient of each part, and then according to ΔH=S*G 2 Calculate the pressure drop of each part, and finally calculate the pressure value of each point according to the initial pressure value of the pipeline, and the calculated pressure value is used as the theoretical value of the pipeline pressure.

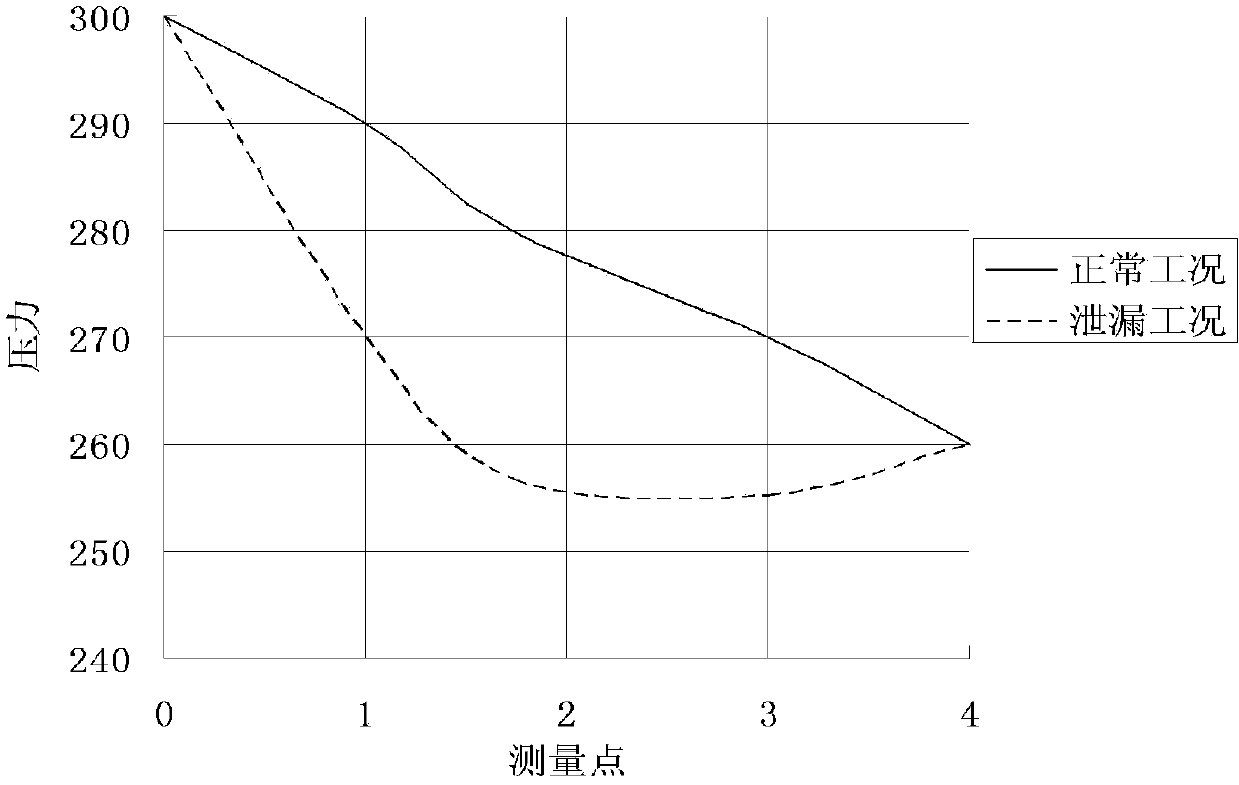

[0025] Inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com