Catalyst for preparing carbon nanotube and its prepn

A technology of carbon nanotubes and catalysts, applied in the field of catalysts and their preparation, can solve the problems of wide distribution of carbon nanotube diameters, failure to meet the requirements of practical applications, troublesome purification process of carbon nanotubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 5.00gLa(NO 3 ) 3 ·6H 2 O, 0.81gFe(NO 3 ) 3 9H 2 O, 2.33gNi(NO 3 ) 2 ·6H 2 O, dissolve it with distilled water, then add 4.60g citric acid. Heat the above solution at 80°C with constant stirring until it evaporates to dryness to obtain a yellow jelly, then carbonize the jelly at 400°C, and finally burn it in a muffle furnace at 800°C and air atmosphere After 4 hours, a black powder was obtained. After grinding the resulting black powder to a size of 60 mesh, the catalyst LaFe 0.2 Ni 0.8 o 3 .

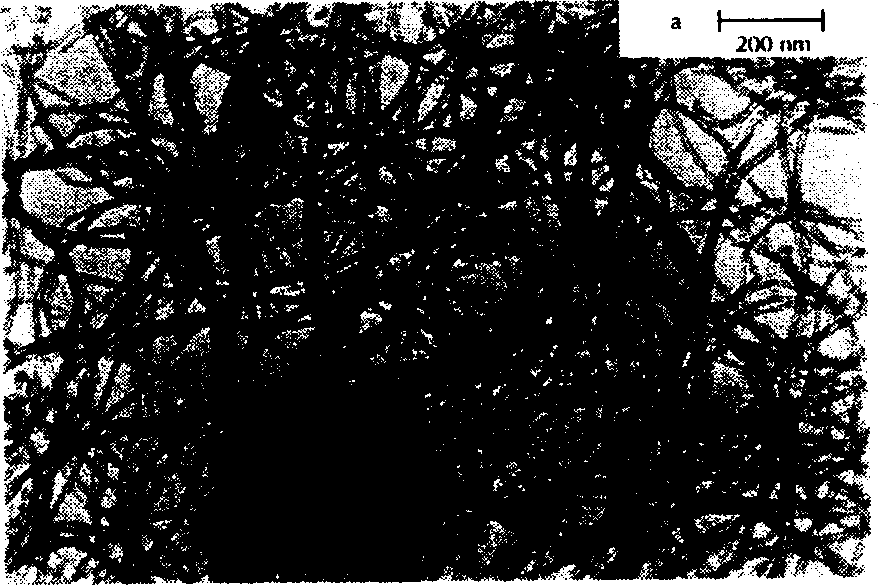

[0036] Will contain 20mg LaFe 0.2 Ni 0.8 o y After putting the quartz boat into the quartz tube, pass N 2 side heat up. When the temperature rises to 700°C, pass H 2 (40ml / min) reduction for half an hour, then change to H 2 (50ml / min), N 2 (140ml / min), C 2 h 2 (16ml / min) mixed gas. After the reaction was carried out for 1 hour, the reaction was stopped, and the product was collected, purified, and dried to obtain 200 mg of carbon nanotubes. The produc...

Embodiment 2

[0038] The same catalyst as in Example 1 was used. Will be loaded with 20mgLaFe 0.2 Ni 0.8 o 3 After putting the quartz boat into the quartz tube, pass N 2 side heat up. When the temperature rises to 700°C, pass H 2 (40ml / min) reduction for half an hour, then change to H 2 (50ml / min) and CH 4 (50ml / min) mixed gas. When the reaction was carried out for 1 hour, the reaction was stopped, and the product was collected, purified, and dried to obtain 160 mg of carbon nanotubes. The yield of the carbon nanotube prepared by the catalyst is 8g / g.catal., and the outer diameter of the carbon nanotube is 5-10nm. The transmission electron micrograph of gained carbon nanotube product is as figure 2 shown.

Embodiment 3

[0040] Weigh 5.0gLa(NO 3 ) 3 ·6H 2 O, 0.2gFe(NO 3 ) 3 9H 2 O, 2.76gNi(NO 3 ) 2 ·6H 2 O, dissolve it with distilled water, then add 4.6g citric acid. Heat the above solution at 80°C with constant stirring until it evaporates to dryness to obtain a yellow jelly, then carbonize the jelly at 400°C for half an hour, and finally in a muffle furnace at 800°C with oxygen (40ml / min) under an atmosphere of burning for 4 hours to obtain a black powder. After grinding the resulting black powder to a size of 60 mesh, the catalyst LaFe 0.05 Ni 0.95 o 3 .

[0041] The preparation conditions of carbon nanotubes are the same as in Example 1. The yield of the carbon nanotube prepared by the catalyst is 10g / g.catal., and the outer diameter of the carbon nanotube is 30-50nm. The transmission electron micrograph of gained carbon nanotube product is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com