Ordered nano-tube array structure electrode material, preparation method and stored energy application

A nanotube array, electrode material technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of low energy density, poor energy storage efficiency, etc., to improve energy storage efficiency, improve service life, high ratio Effects of capacitance and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

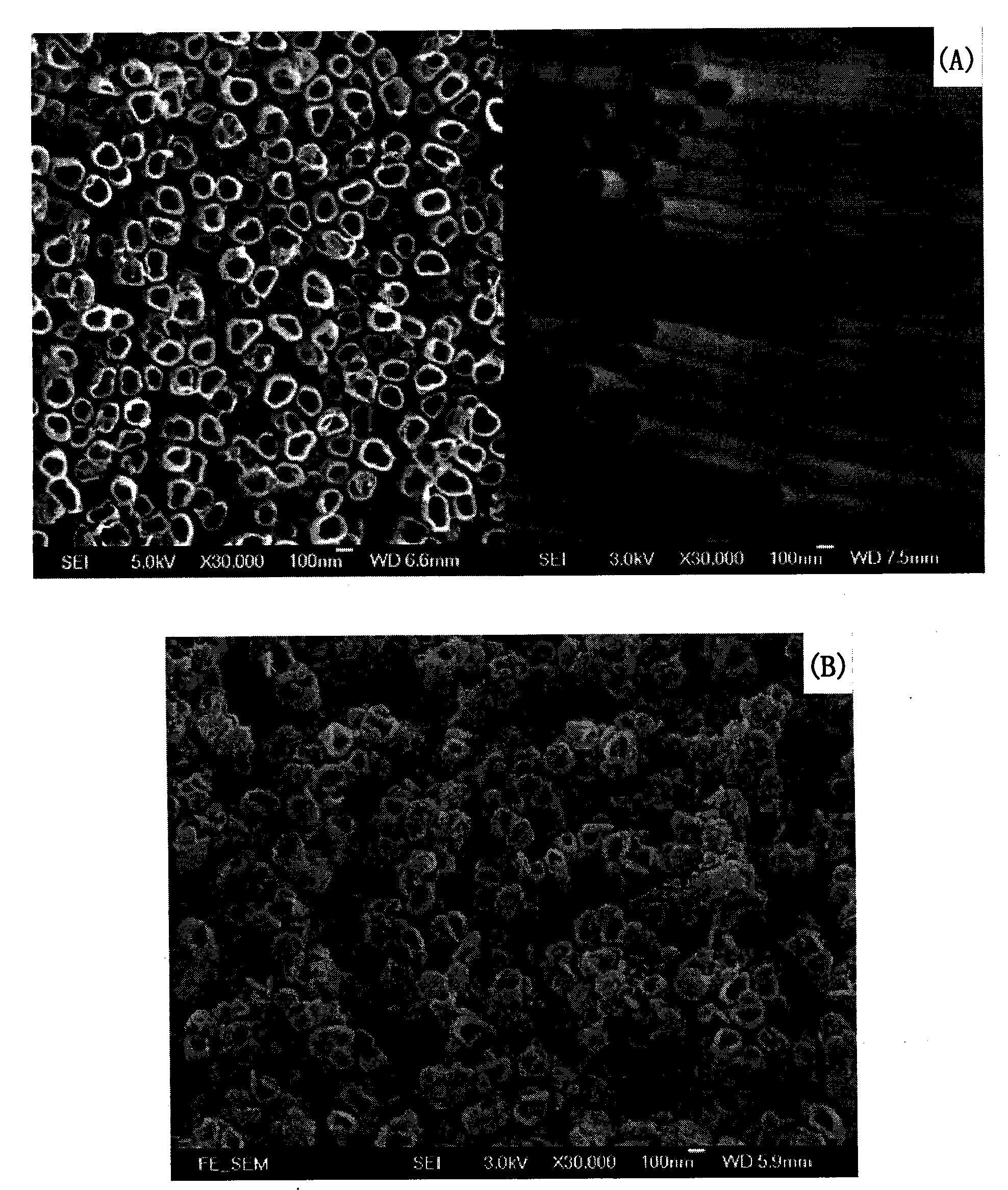

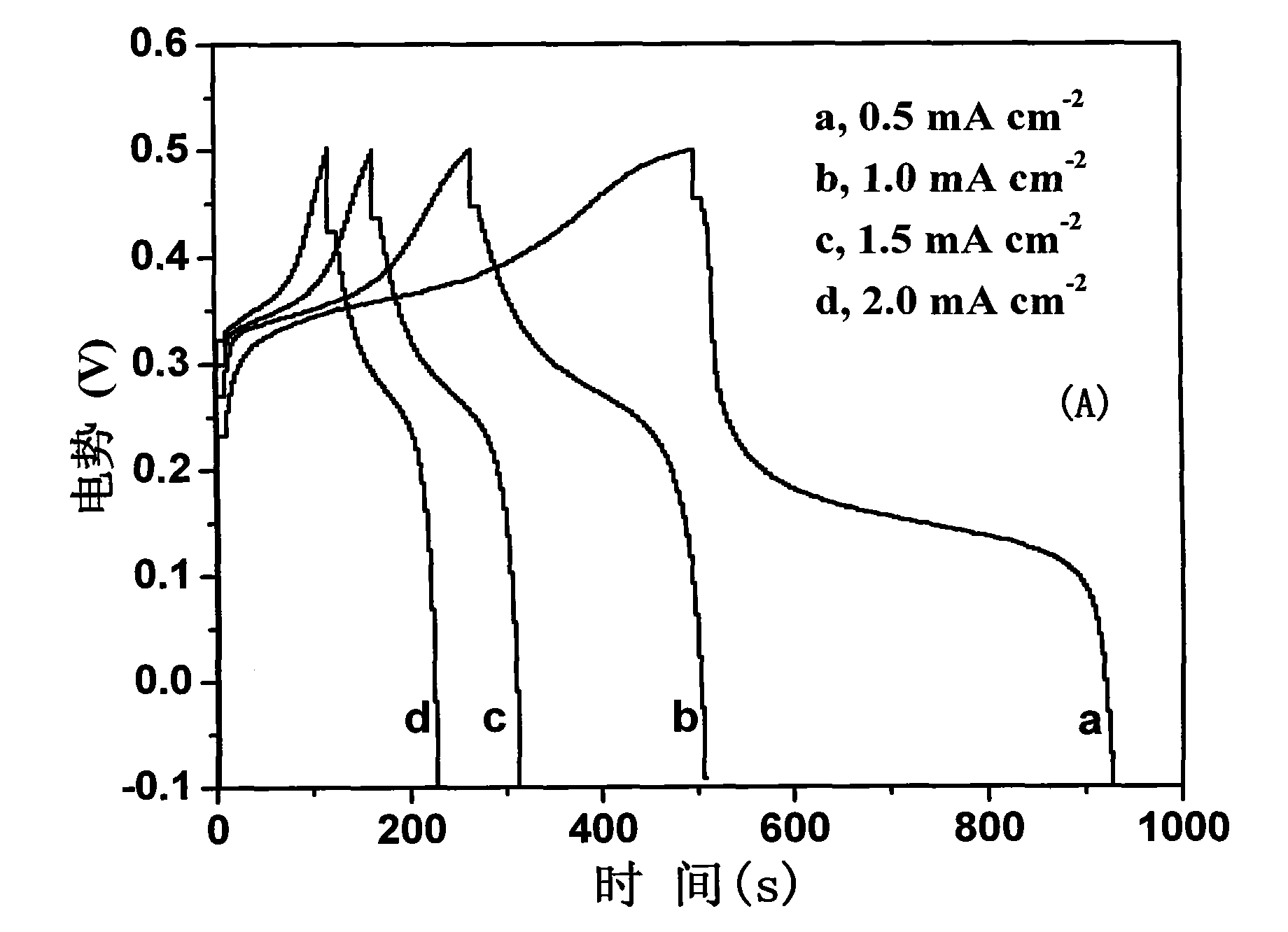

[0022] A supercapacitor electrode material with an ordered nanotube array structure. Firstly, titanium dioxide nanotube arrays with independent tube walls, uniform distribution of tube holes, and adjustable tube diameters are grown on both sides of the base material titanium sheet as the rigid skeleton of the electrode, and then electrochemically active metal oxides are deposited on the nanotube walls to form a large A functional electrode material with a coaxial heterogeneous nanotube array structure in which the specific surface area is arranged in an orderly manner, and is applied to a Faraday supercapacitor.

Embodiment 2

[0024] The preparation method of supercapacitor electrode material of the present invention is as follows:

[0025] Firstly, the self-template anodic oxidation reaction synthesis method is adopted. After the first anodic oxidation reaction of the titanium sheet, the titanium dioxide film layer on the surface is removed by ultrasonic treatment, and the titanium-based titanium dioxide nanotubes are used as a self-template for at least two electrochemical anodic oxidations. reaction to generate titanium dioxide with an ordered nanotube array structure with independent tube walls, uniform tube hole distribution, and adjustable tube diameter. Secondly, the electrochemical deposition synthesis method is adopted, the titanium dioxide nanotube array prepared above is used as the electrode carrier, and the transition metal ion or noble metal ion aqueous solution is used as the reaction electrolyte, and the electrochemical activity is synthesized in situ on the nanotube wall by a cyclic ...

Embodiment 3

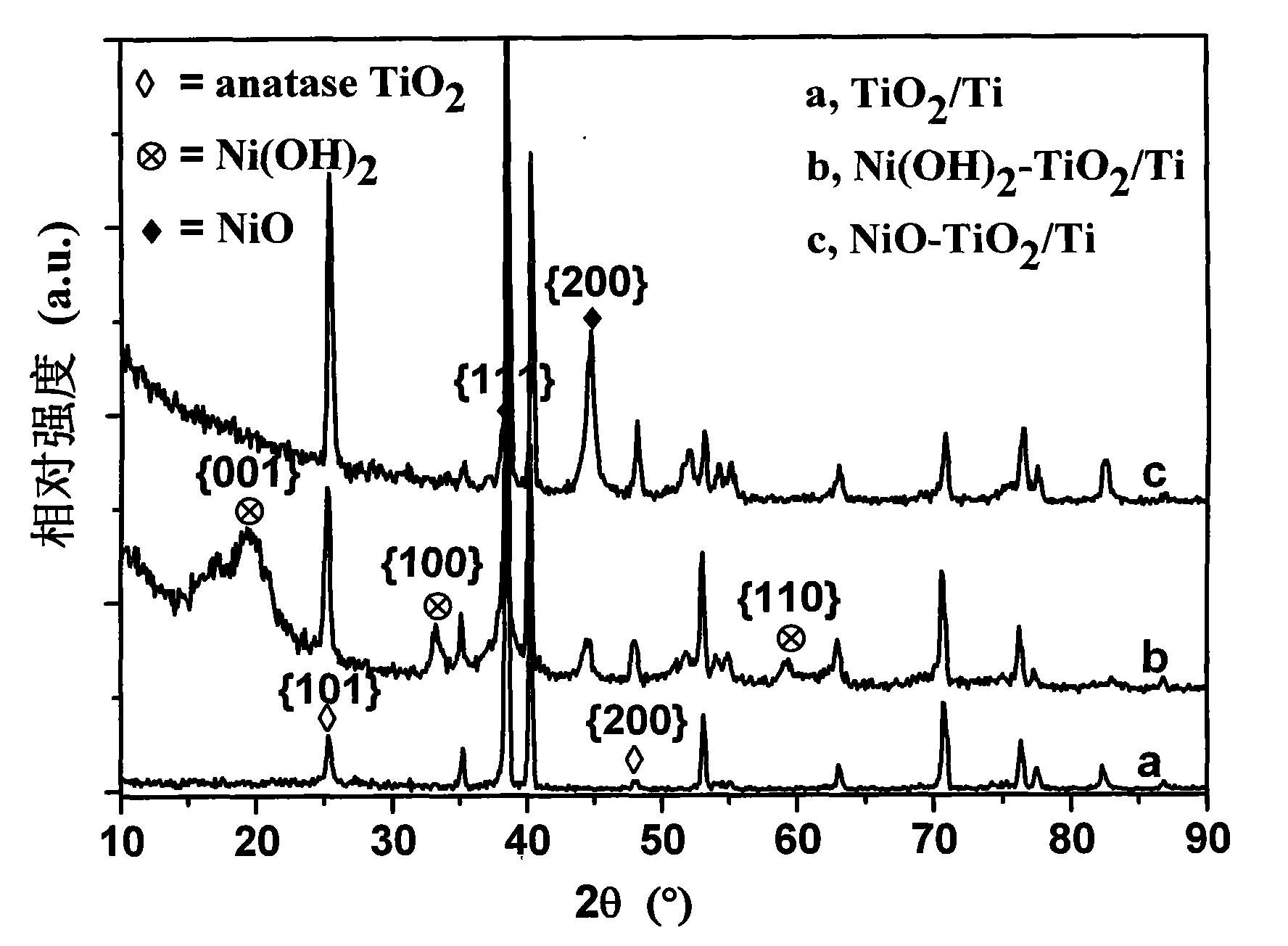

[0029] This example is NiO-TiO 2 Ordered nanotube array structure supercapacitor electrode materials and their specific energy storage applications. The metal titanium sheet was ultrasonically cleaned in acetone and ethanol solvents for 20 minutes, and then cleaned in HF (3.3M)-HNO 3(5.6M) in aqueous solution for 15s chemical polishing treatment to form a fresh pure titanium metal surface. A two-electrode electrochemical reaction system was established, with the titanium sheet as the anode and the platinum sheet as the cathode, and the H 3 PO 4 The ethylene glycol / water (50 / 50, V / V) mixed solution of (0.5M)-HF (0.15M) is used as the working electrolyte, reacted for 2h under the condition of constant voltage 30V, and the titanium prepared by self-template anodic oxidation reaction synthesis method Titanium dioxide nanotubes are grown on both sides of the sheet as an electrode carrier material, and after heat treatment at 450°C for 2 hours, the titanium dioxide nanotubes are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com