Low rank coal high temperature flue gas drying method and device

A technology of high-temperature flue gas and low-rank coal, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., and can solve the problems of low processing efficiency, low efficiency, and low drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

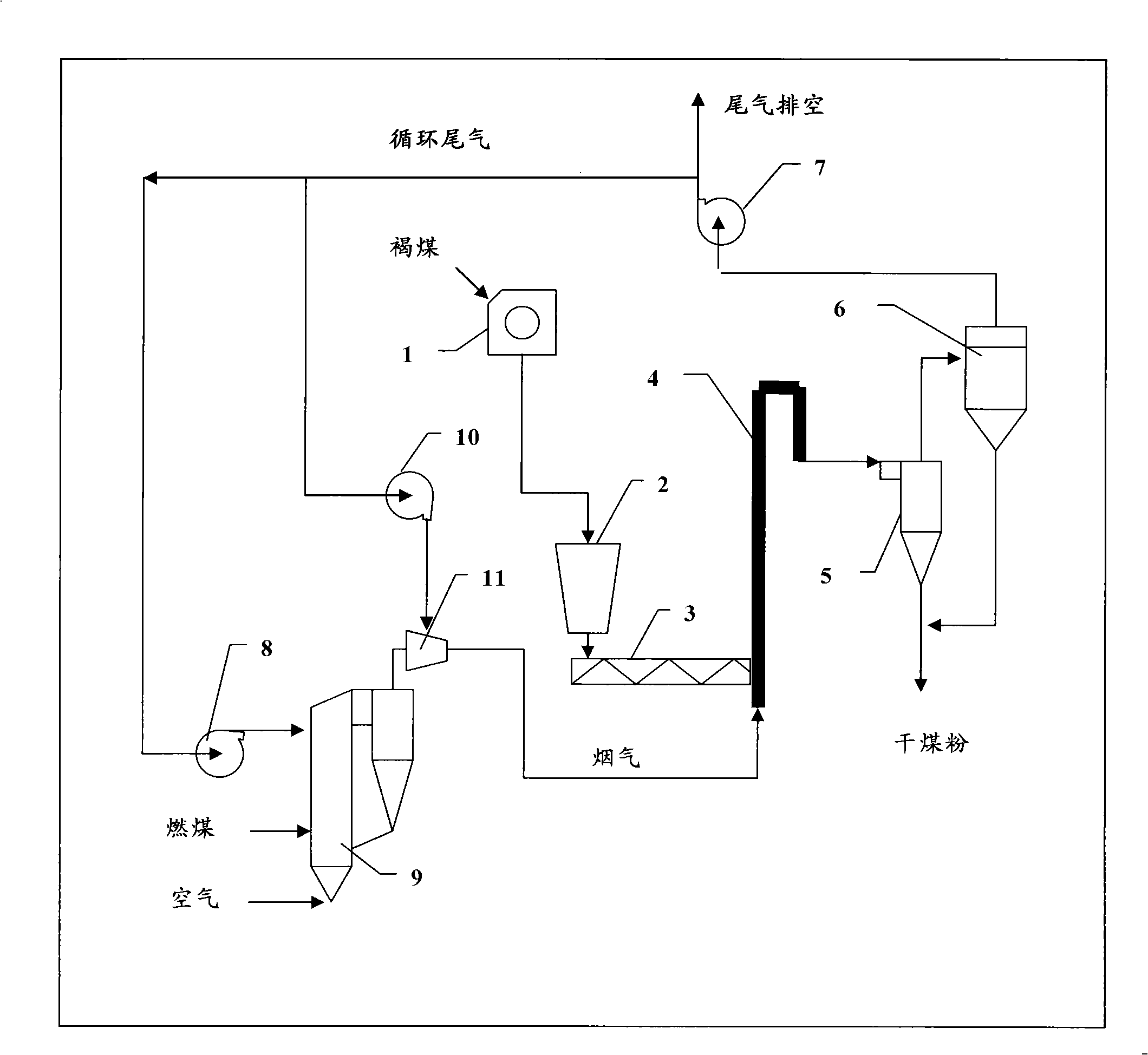

[0075] See attached figure 1 , the lignite with a moisture content of 31-38% by weight is pulverized into pulverized coal with a particle size of less than 3mm by the pulverizer 1 and sent to the silo 2 for storage. The pulverized coal is sent to the air dryer 4 through the quantitative feeder 3 for drying. The drying medium is the high-temperature flue gas formed in the mixing chamber 11, the oxygen content of the high-temperature flue gas is controlled at about 8% by volume, and the temperature is controlled at about 720°C. Coal powder and high-temperature flue gas meet at the inlet of dryer 4 and stay in the drying pipe for 3-5 seconds. The flue gas carrying pulverized coal from the dryer 4 passes through the cyclone separator 5 to separate the pulverized coal from the flue gas, and the dry pulverized coal is discharged from the lower part of the cyclone separator 5. The outlet temperature of the pulverized coal is controlled at 80-120°C and the water content is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com