Plant and process for removing carbon dioxide from gas streams

A technology of carbon dioxide and gas flow, applied in chemical instruments and methods, separation methods, liquefaction, etc., can solve the problems of insufficient amplification, large quantities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

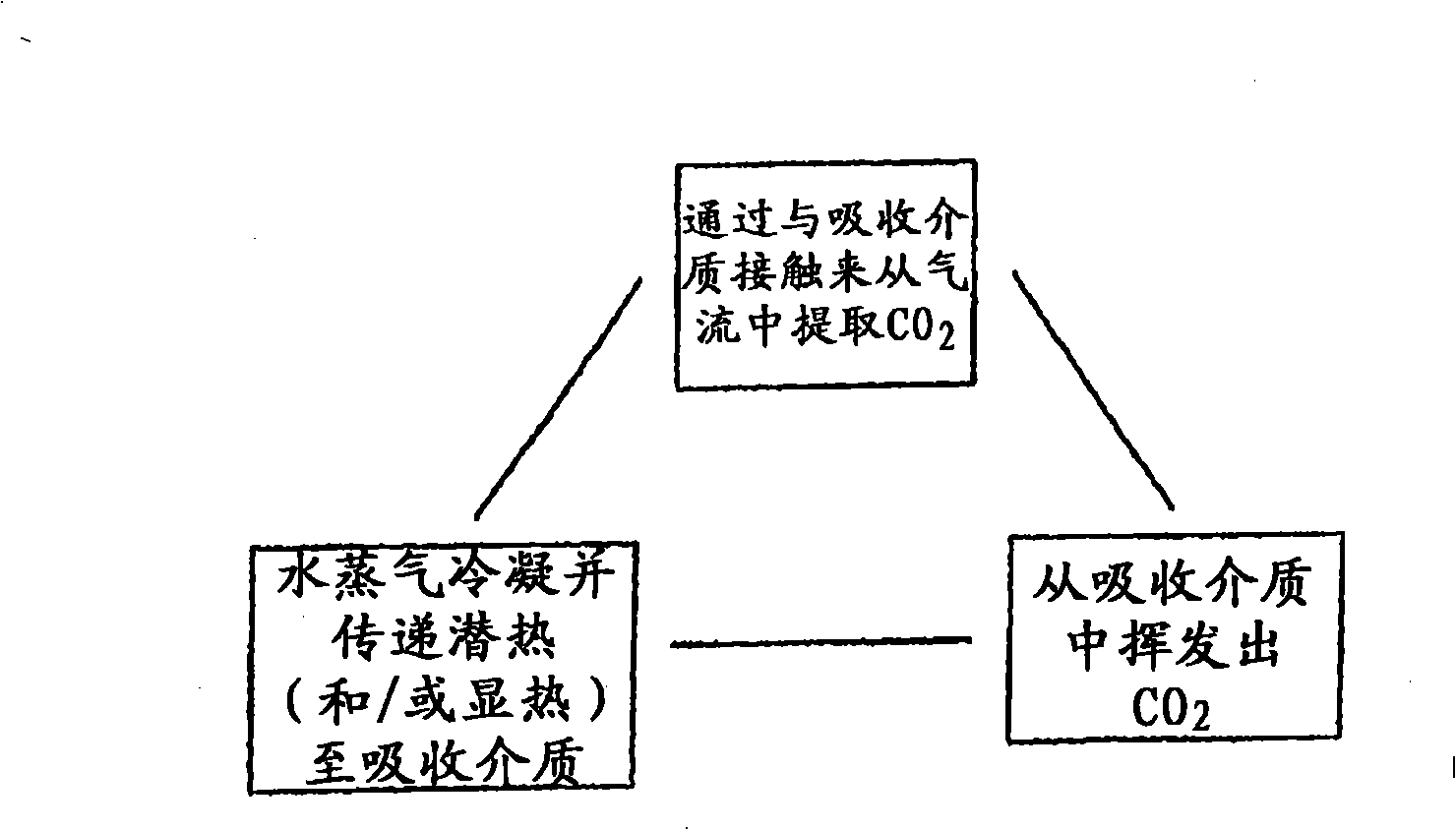

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3 and 4

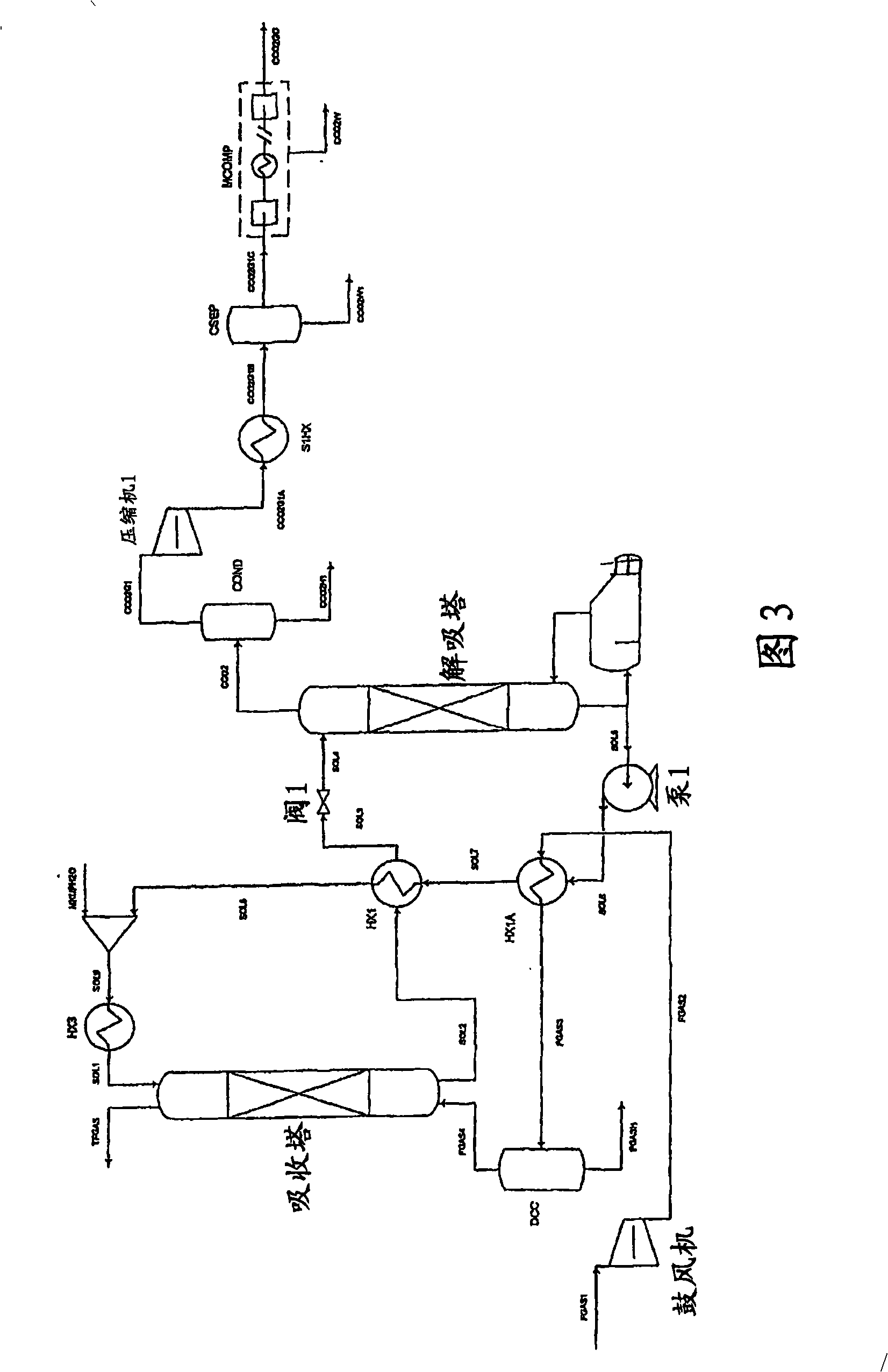

[0129] The flowchart shown in Figure 3 is similar to figure 2 The flow diagram is shown and includes the absorber, desorber and reboiler as well as several other unit operations, such as fans, designed for handling flue gases from lignite fired power plants. In summary, a flue gas stream designated FGAS4 that has been pretreated in a direct contact cooler (DCC) (essentially a knockout drum used to remove condensate) and heat exchanger HX1A is fed to absorption tower. The treated carbon dioxide-depleted flue gas is withdrawn from the absorber as stream TFGAS, and the carbon dioxide-depleted solvent stream is fed to the absorber as stream SOL1, and the carbon dioxide-enriched solvent stream is fed as stream SOL2 to the absorption tower. The carbon dioxide-rich stream SOL4 is fed to the desorption column via a throttle valve, and the carbon dioxide-depleted stream SOL5 is returned to the absorption column via heat exchangers HX1A, HX1 and HX3. A stream enriched in carbon dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com