Temperature cascade PID (Proportion Integration Differentiation) control system of high-temperature high-pressure testing device and control method thereof

A high temperature and high pressure, test device technology, applied in the direction of temperature control, control/regulation system, electric controller, etc., can solve the problems of limited application scope, difficult control of heating and cooling speed, complicated heating device equipment, etc., to solve the problem of heating speed too fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The utility model will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

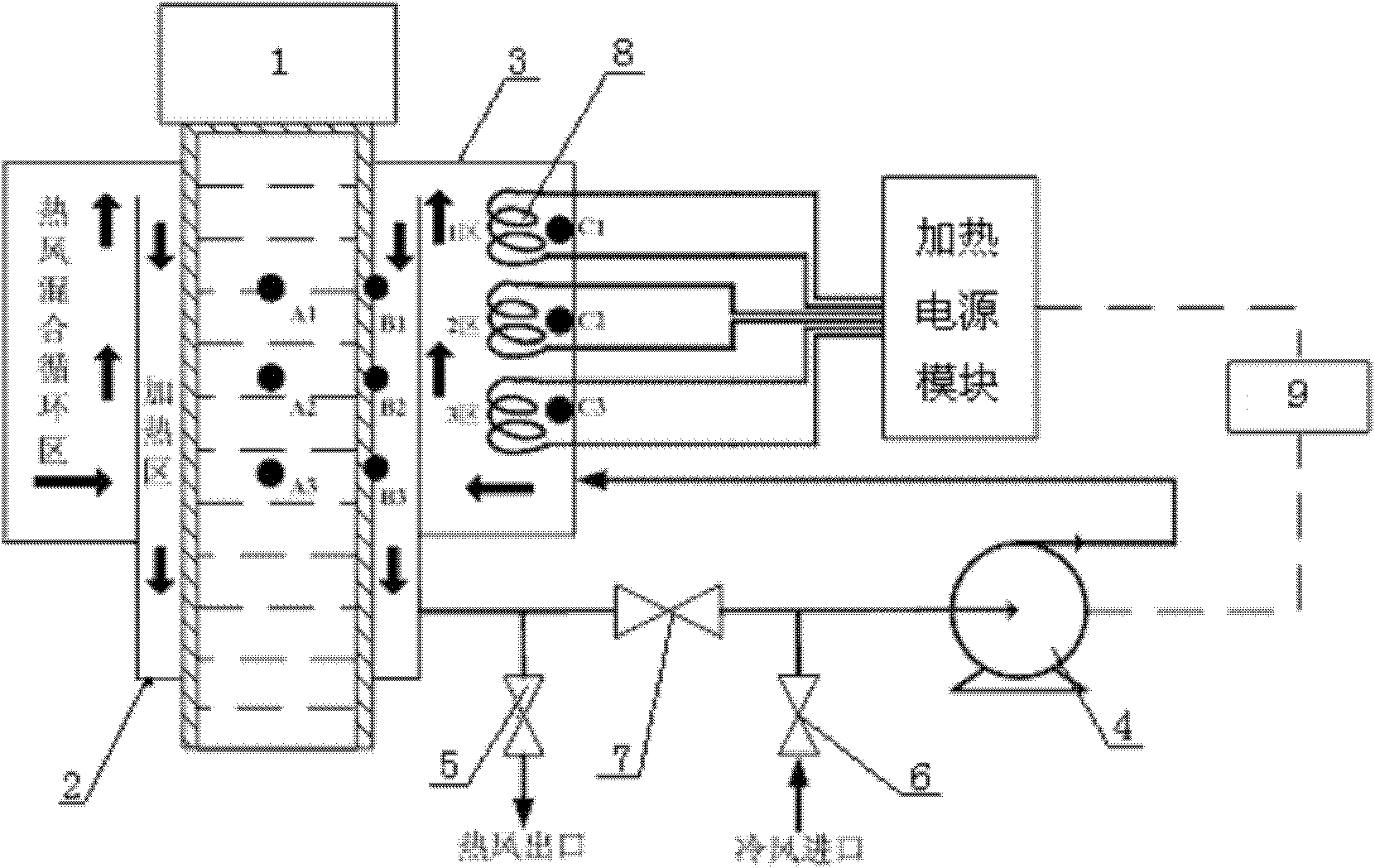

[0024] see figure 1 , the present invention consists of the following modules:

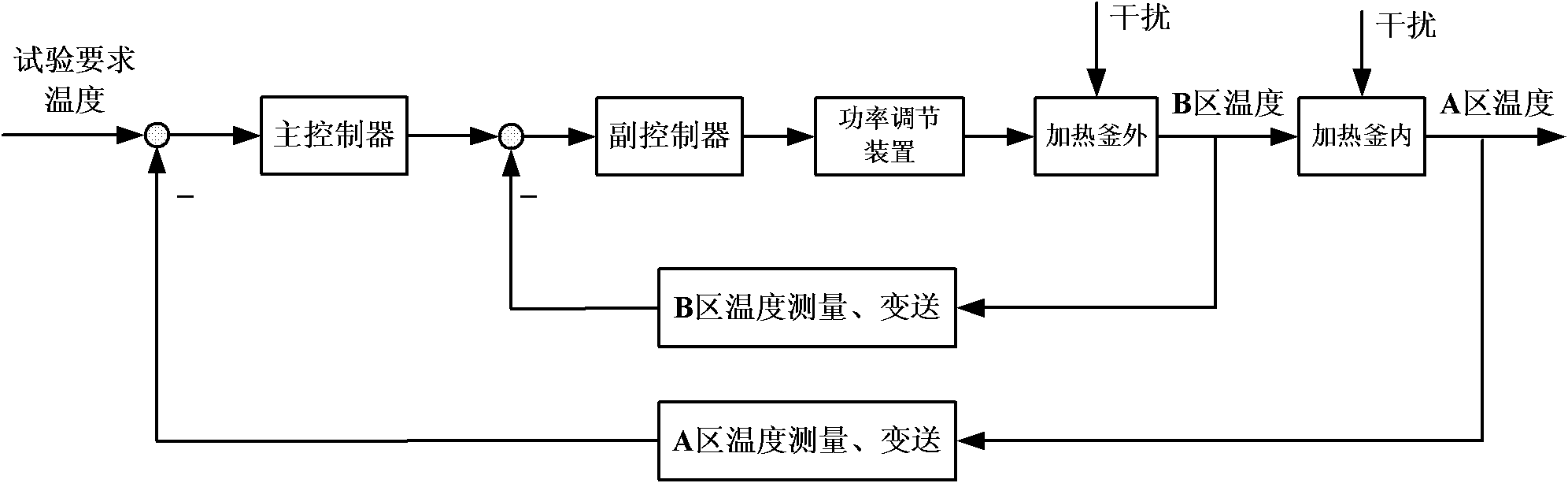

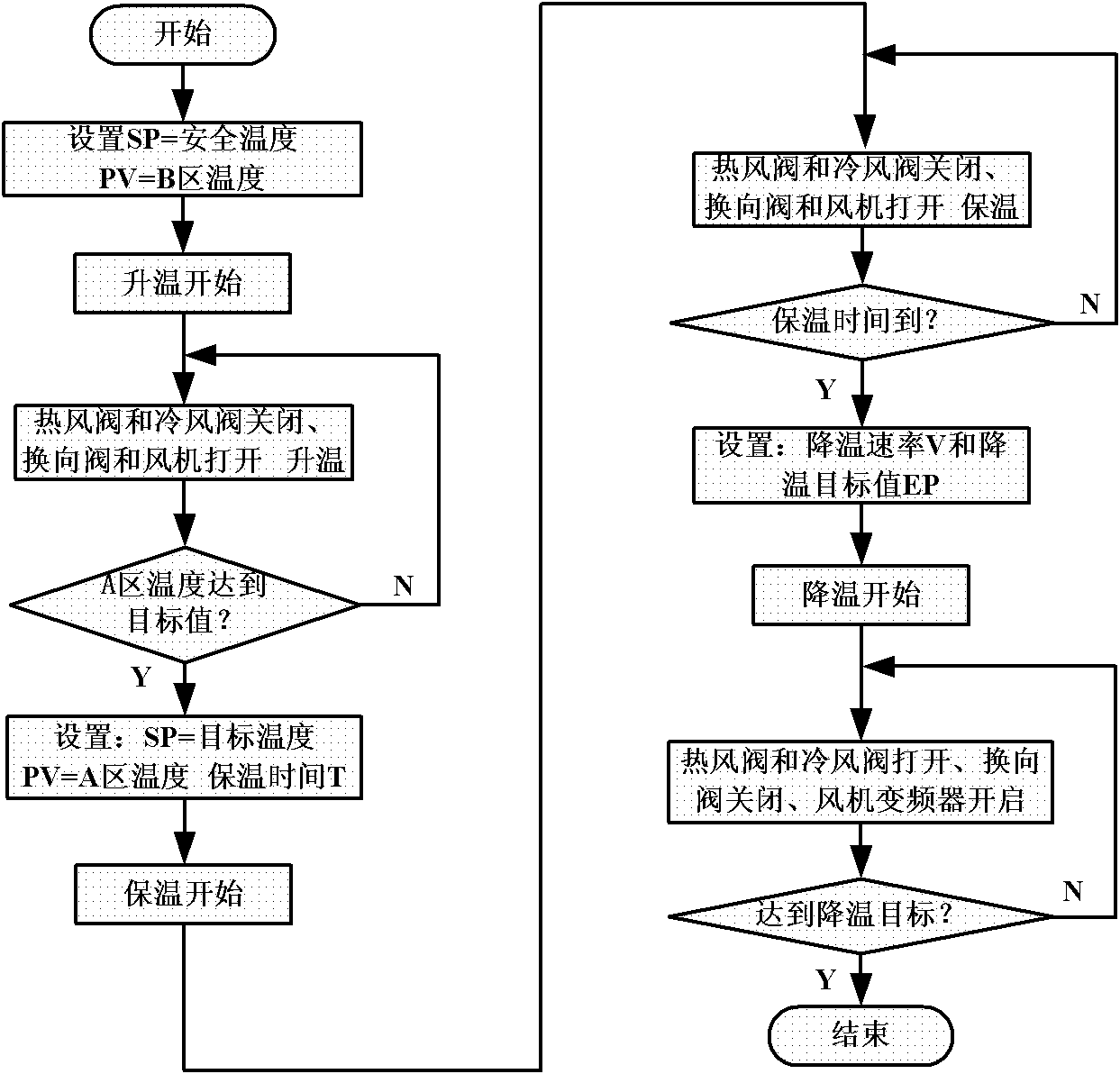

[0025] The hot air mixing heating module includes a heating ax 1, a guide tube 2, a heating tube 3, and a heating body 8. The outer diameter of the heating ax 1 is sequentially covered with a guide tube 2 and a heating tube 3 to form a heating area, and the heating body 8 is arranged on the guide tube. 2 and the heating cylinder 3; the annular sealing area outside the ultra-high pressure vessel is a hot air mixed circulation heating zone. The resistance heating body is divided into three areas and arranged evenly between the heating cylinder and the guide cylinder according to certain rules, and the circulating air is heated between them, and finally Through conduction heating, the medium in the ultra-high pressure vessel reaches the temperature required for the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com