Split type electric pressure cooker

An electric pressure cooker, split-type technology, applied in the field of pressure cooker, can solve the problems of poor food cooking effect, waste of energy, long working hours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

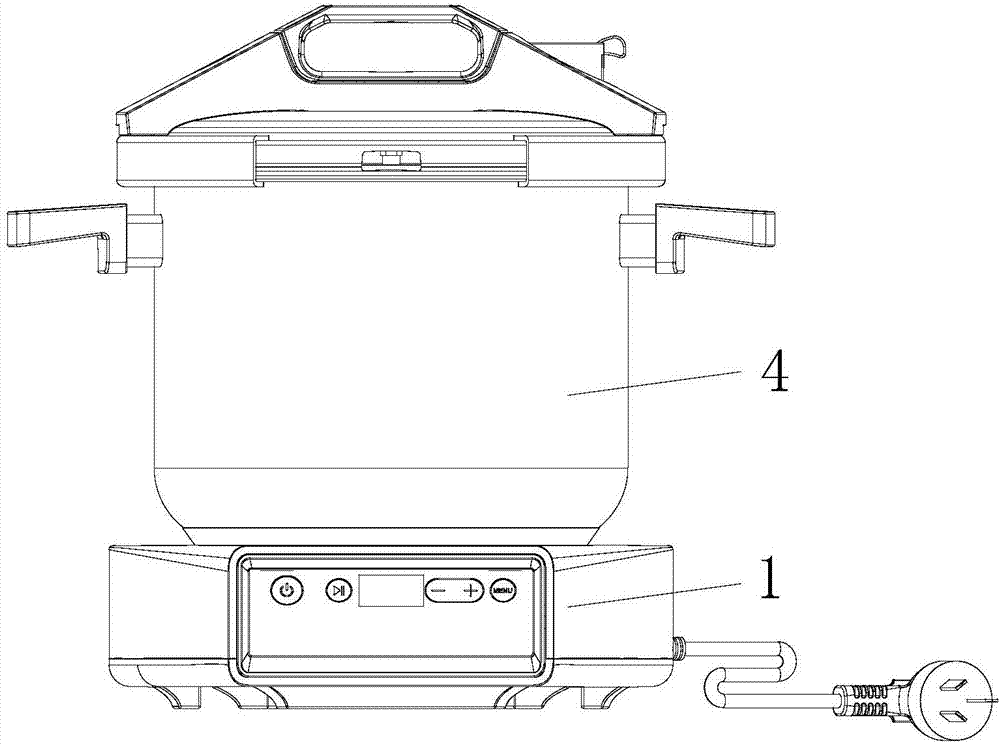

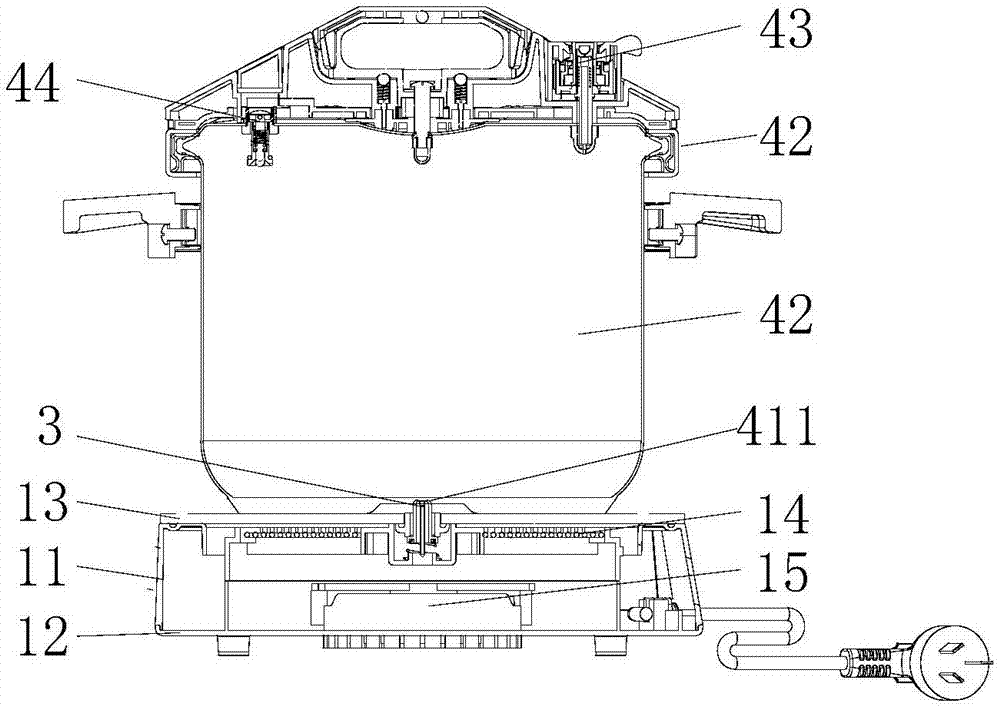

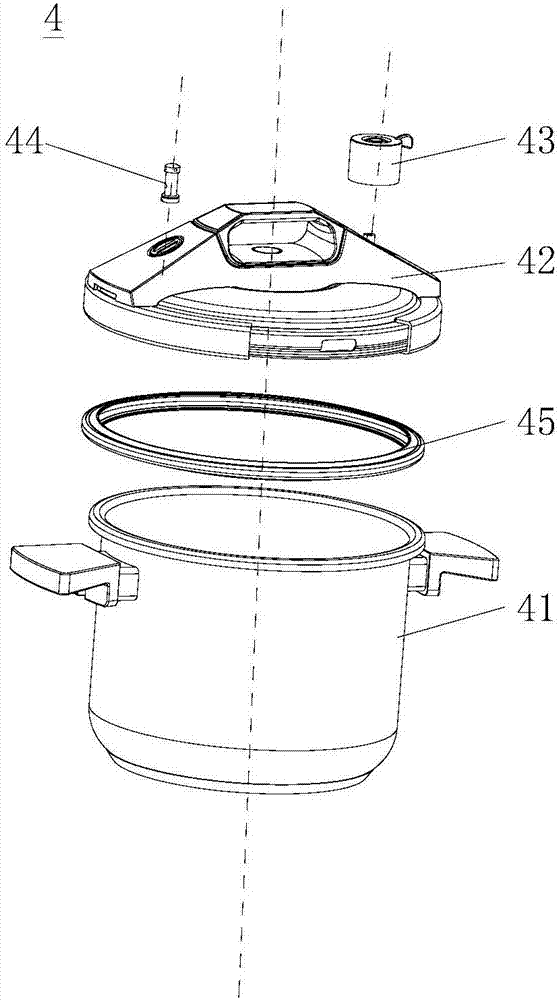

[0034] The present invention proposes a split type electric pressure cooker, which includes: a heating chassis, the heating chassis is provided with a main body and a bottom cover, a microcrystalline plate is placed at the upper opening of the main body, and a coil disk, A fan and a power board assembly capable of adjusting the heating power of the coil disk, the bottom cover is correspondingly engaged with the lower opening of the main body, the power board assembly is electrically connected to the coil disk and the fan; the control board assembly, Installed on the side wall of the main body, the power board assembly is electrically connected to the control board assembly; the heat-sensitive temperature element can be telescopically installed between the microcrystalline board and the coil disk, and its upper end protrudes On the upper surface of the microcrystalline plate, the heat-sensitive temperature element is connected to the power board assembly; when the pressure cooke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com