Temperature control method of electric heating kitchenware

An electric cooking utensil and temperature control technology, which is applied in the direction of temperature control using electric methods, household appliances, kitchen utensils, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

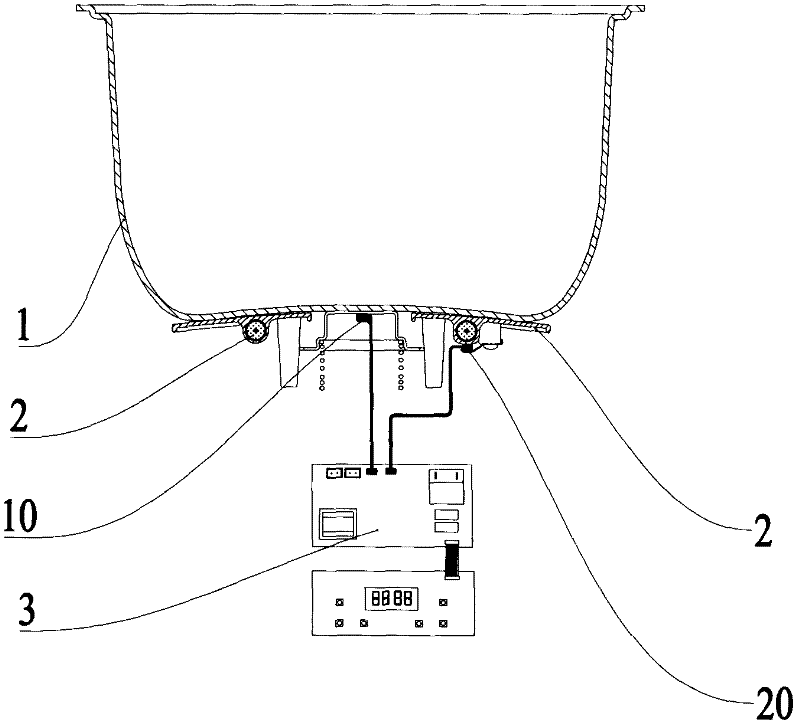

[0023] like figure 1 As shown, an electric heating cooker is a soup pot used for cooking soup, including an inner pot 1, a heater 2 for heating the inner pot 1, and an inner pot temperature detector for detecting the temperature of the inner pot 1 10. The heater temperature detector 20 and the controller 3 that detect the temperature of the heater 2, the inner pot temperature detector 10, the heater temperature detector 20 and the heater 2 are respectively connected to the controller 3 with electrical signals . The inner pot 1 is placed on the upper surface of the heater 2, and the heat emitted by the heater 2 is mainly transferred to the inner pot 1 through direct conduction. The controller 3 controls the on and off of the heater 2 or the magnitude of the heating power through a thyristor circuit.

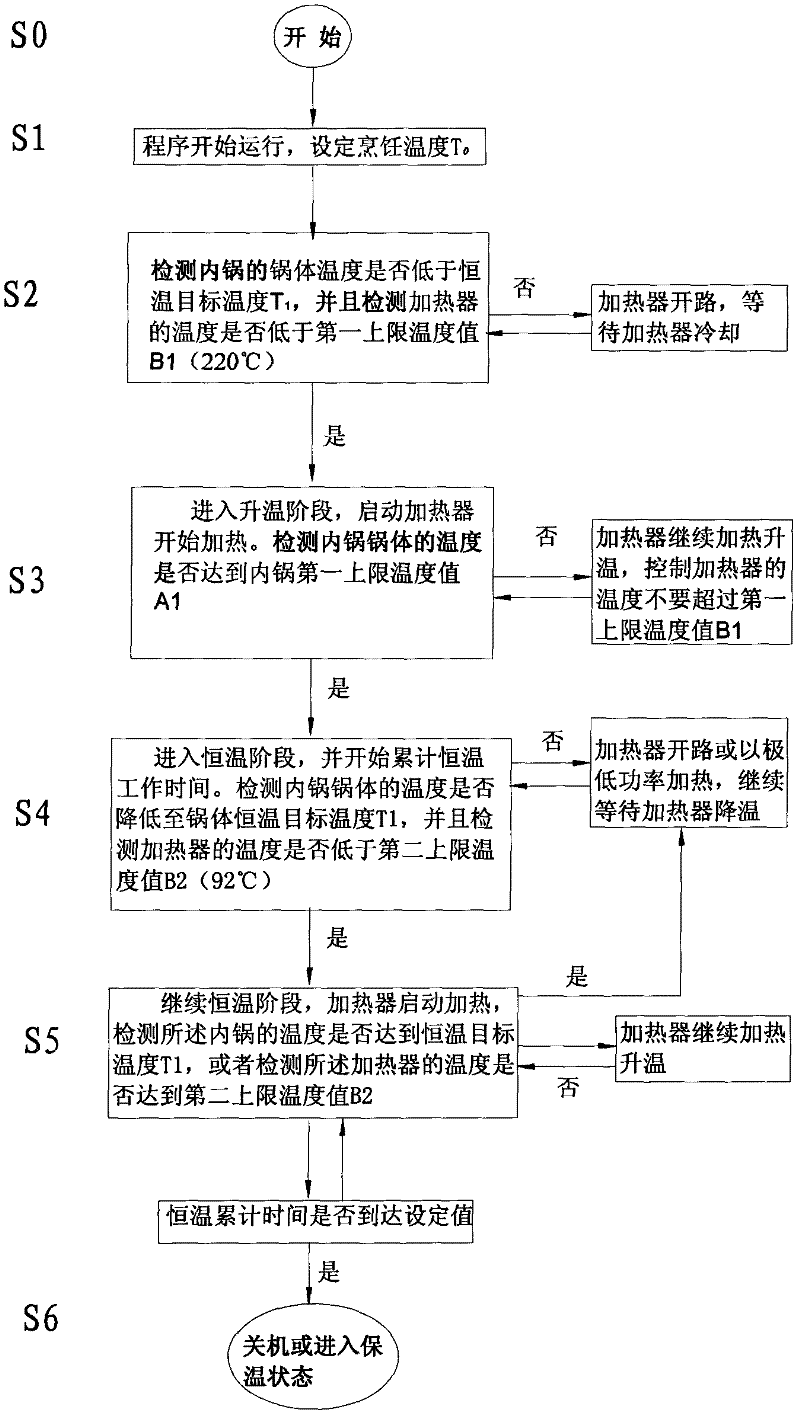

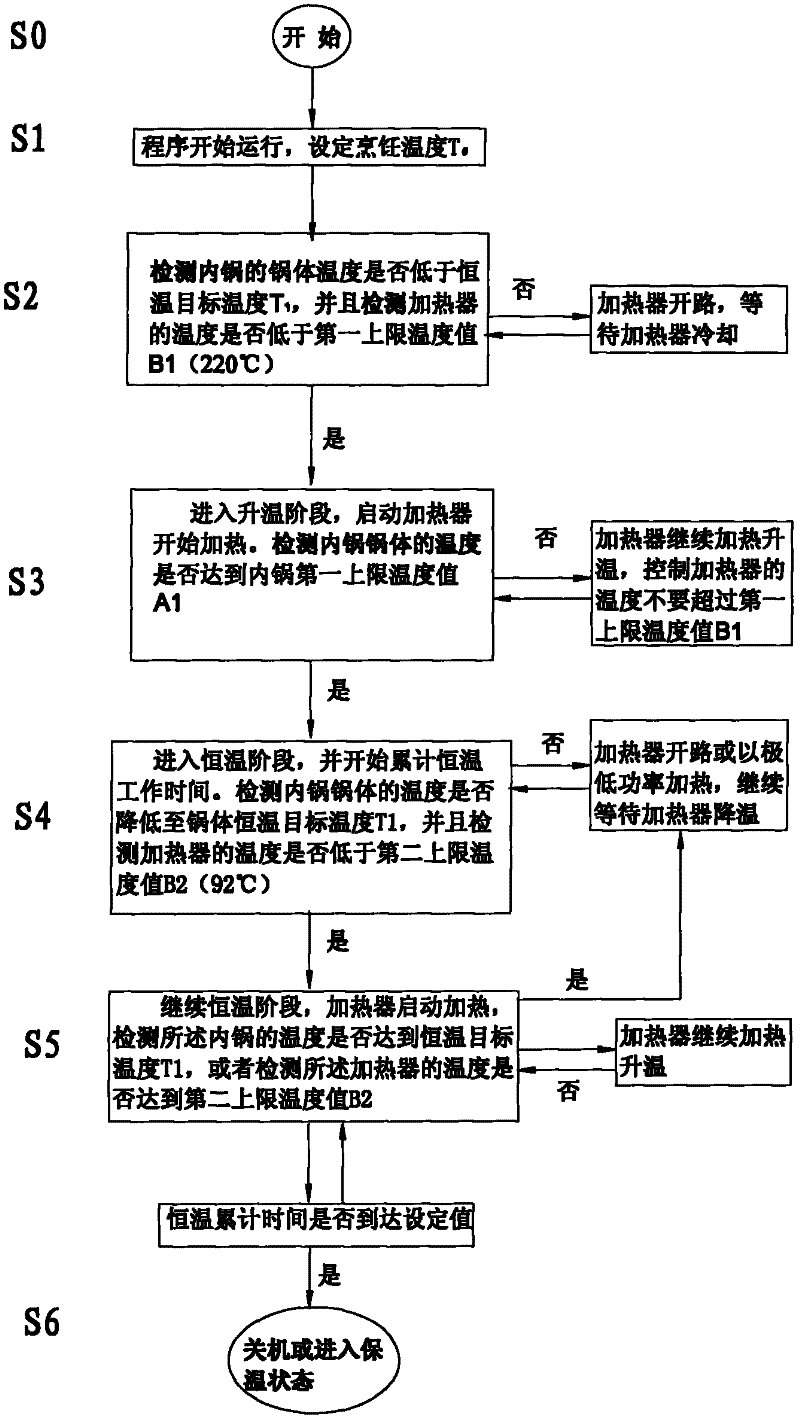

[0024] In order to implement constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com