Buffering hydraulic oil cylinder

A technology of hydraulic oil cylinder and buffer box, applied in the field of hydraulic cylinder, can solve the problems of collision of running speed cylinder and reduction of cylinder life, and achieve the effect of slowing down collision, ensuring normal operation and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

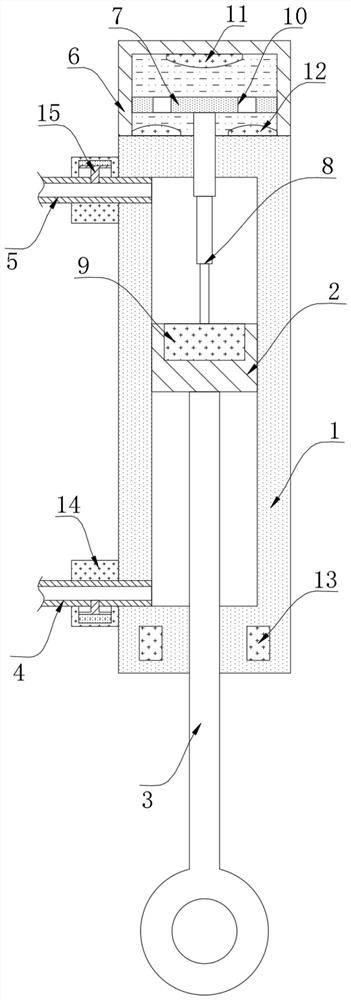

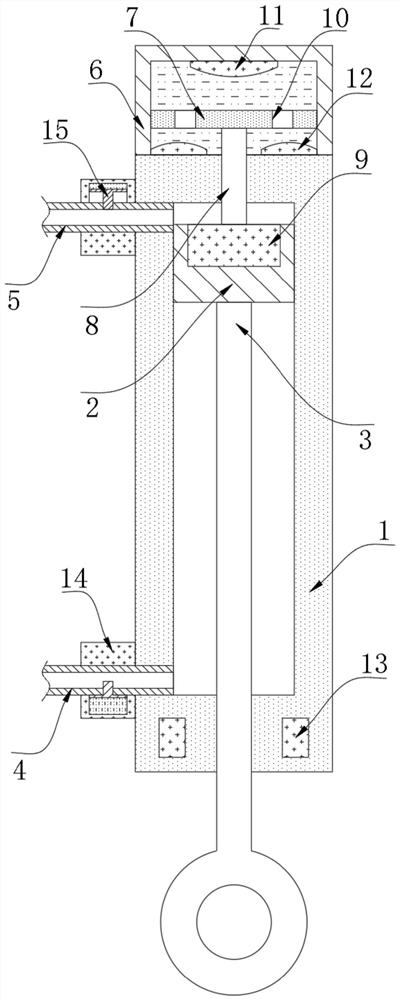

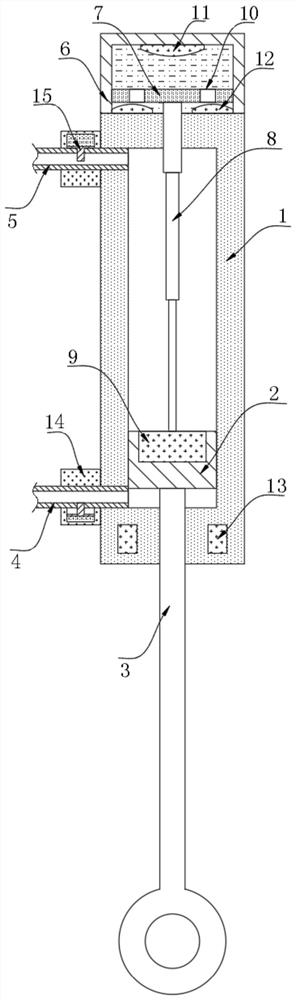

[0020] refer to Figure 1-3 , a buffer hydraulic oil cylinder, comprising a cylinder body 1, the inner wall of the cylinder body 1 is sealed and slidably connected with a piston 2, the side wall of the piston 2 is fixed with a pull rod 3 penetrating through the cylinder body 1, and the side wall of the cylinder body 1 is inserted with a retractable Pipe 4 and extension pipe 5, the outer wall of cylinder body 1 is fixed with buffer box 6, the inner wall of buffer box 6 is sealed and slidably connected with push plate 7, the side wall of push plate 7 is fixed with telescopic rod 8, and the side wall of piston 2 is fixed with Magnet 9, expansion rod 8 run through the side wall of cylinder body 1 and are fixed with magnet block 9, and the side wall of expansion rod 8 is sealed and slidably connected with cylinder body 1, and telescopic section is positioned at cylinder body 1 inside, and the inside of buffer box 6 is provided with There is a buffer mechanism, two current limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com