Hoisting device and hoisting method for prefabricated panel

A technology of prefabricated wall panels and hoisting devices, which is applied in the directions of transportation, packaging, and load hanging components, etc., which can solve problems such as prefabricated wall panels shaking, structural strength needs to be improved, and potential safety hazards of prefabricated wall panels, so as to increase safety and reliability , to protect safety and avoid secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

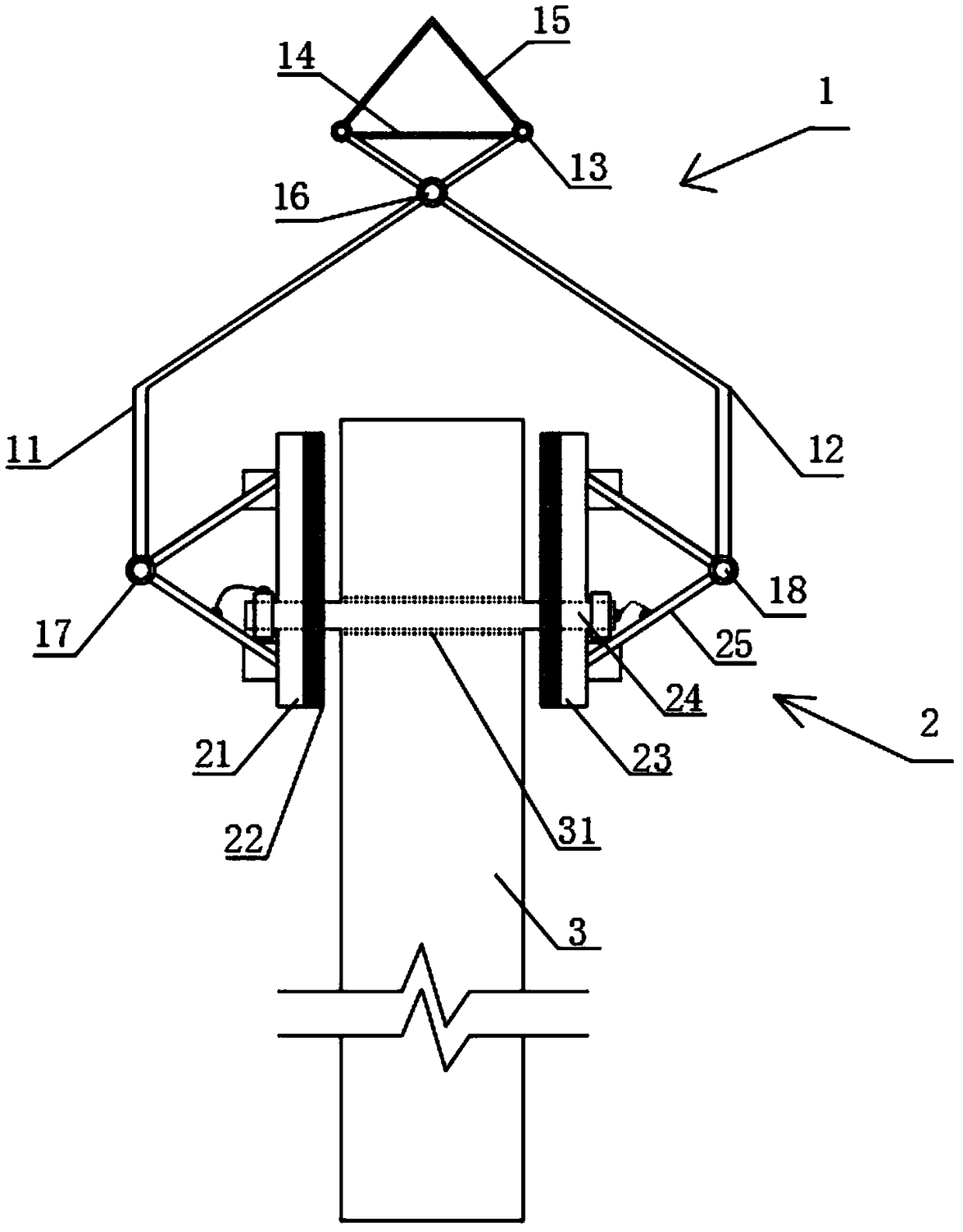

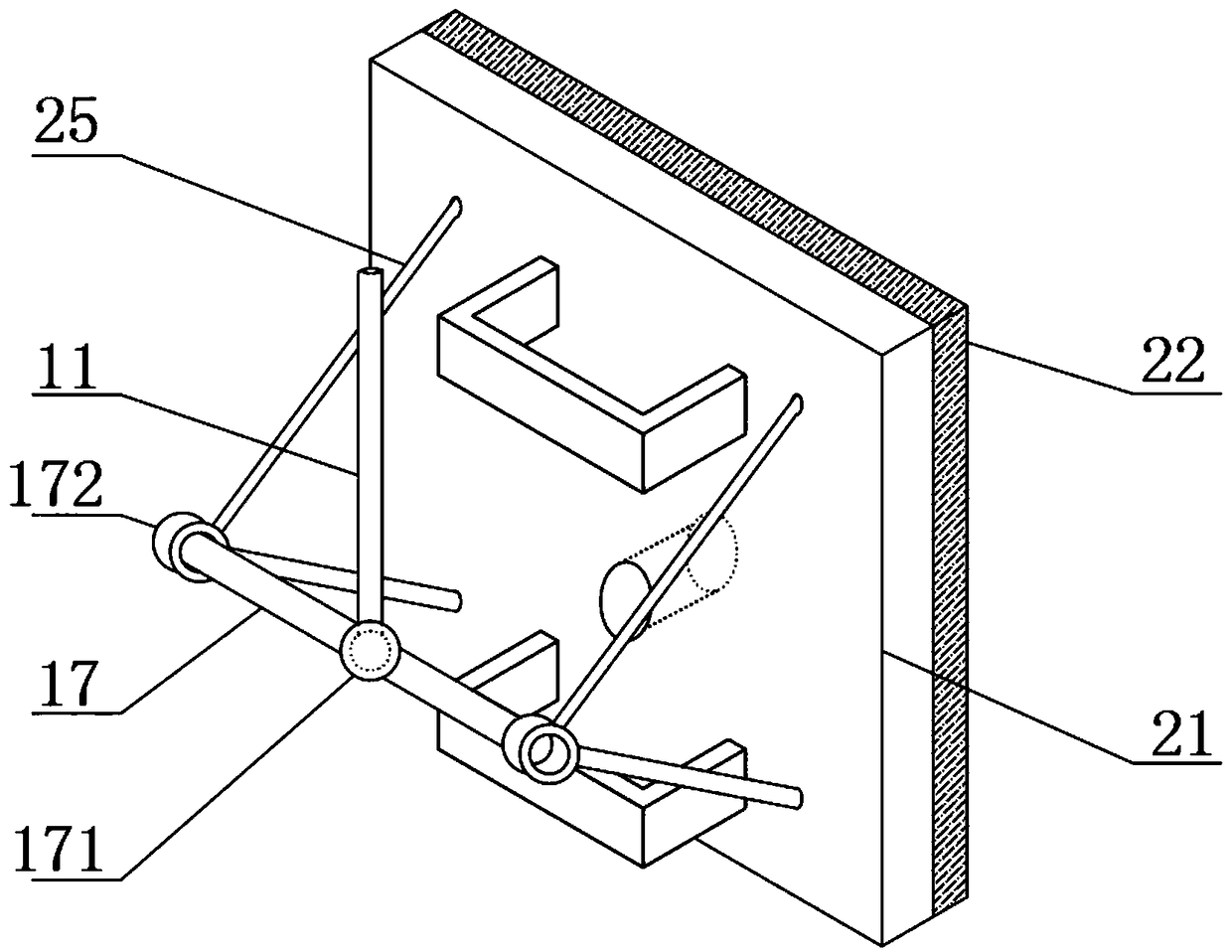

[0042] For ease of understanding, the specific structure of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0043] like figure 1As shown, the hoisting device includes a lifting part 1 for lifting the prefabricated wall panel 3 and a clamp part 2 for fixing the position of the prefabricated wall panel 3. The clamp part 2 is connected to the lower end of the lifting part 1, and the clamp part 2 is provided with a The hoisting anchor bolt 24 in the hoisting hole 31 that the prefabricated wall panel 3 offers.

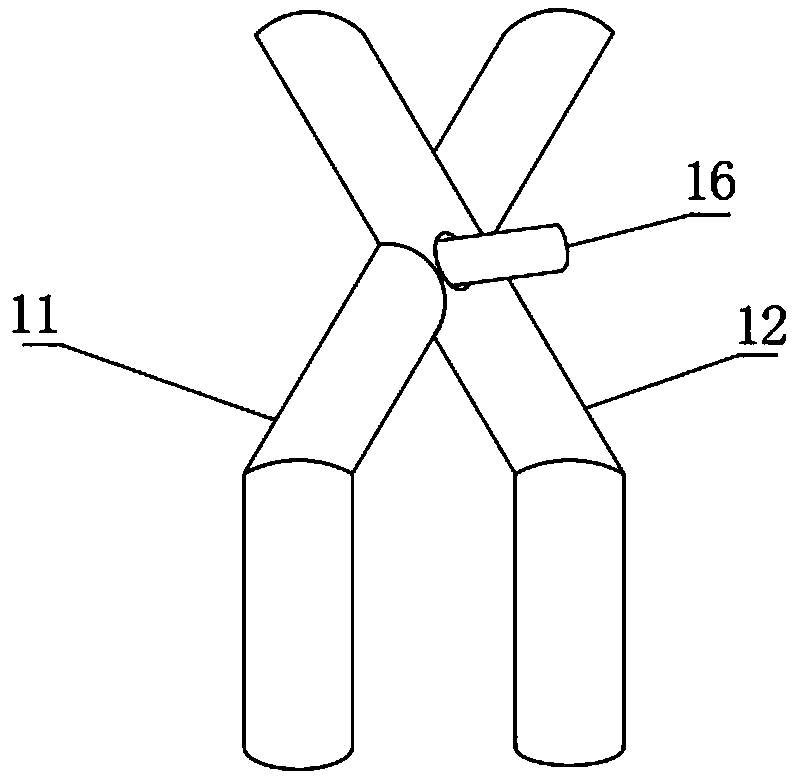

[0044] The hoisting part 1 includes a first cross boom 11 and a second cross boom 12 placed crosswise for converting the active force generated by the crane into clamping force, the first cross boom 11 and the second cross boom 12 Both are composed of an upper boom and a lower boom, wherein the length of the lower boom and the length of the shaft of the upper boom below the hinge, the ratio of the sum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com