Pump Driving Apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

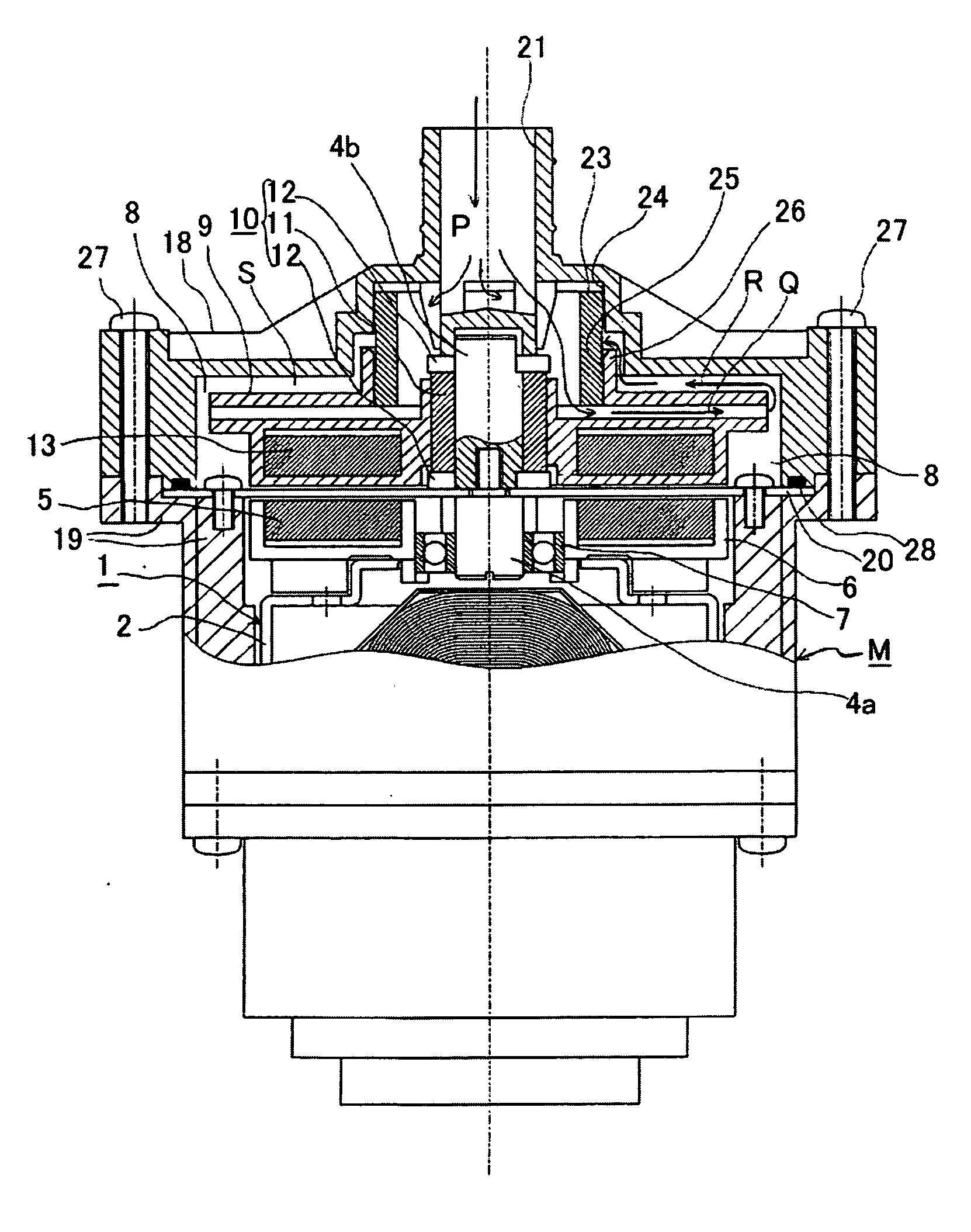

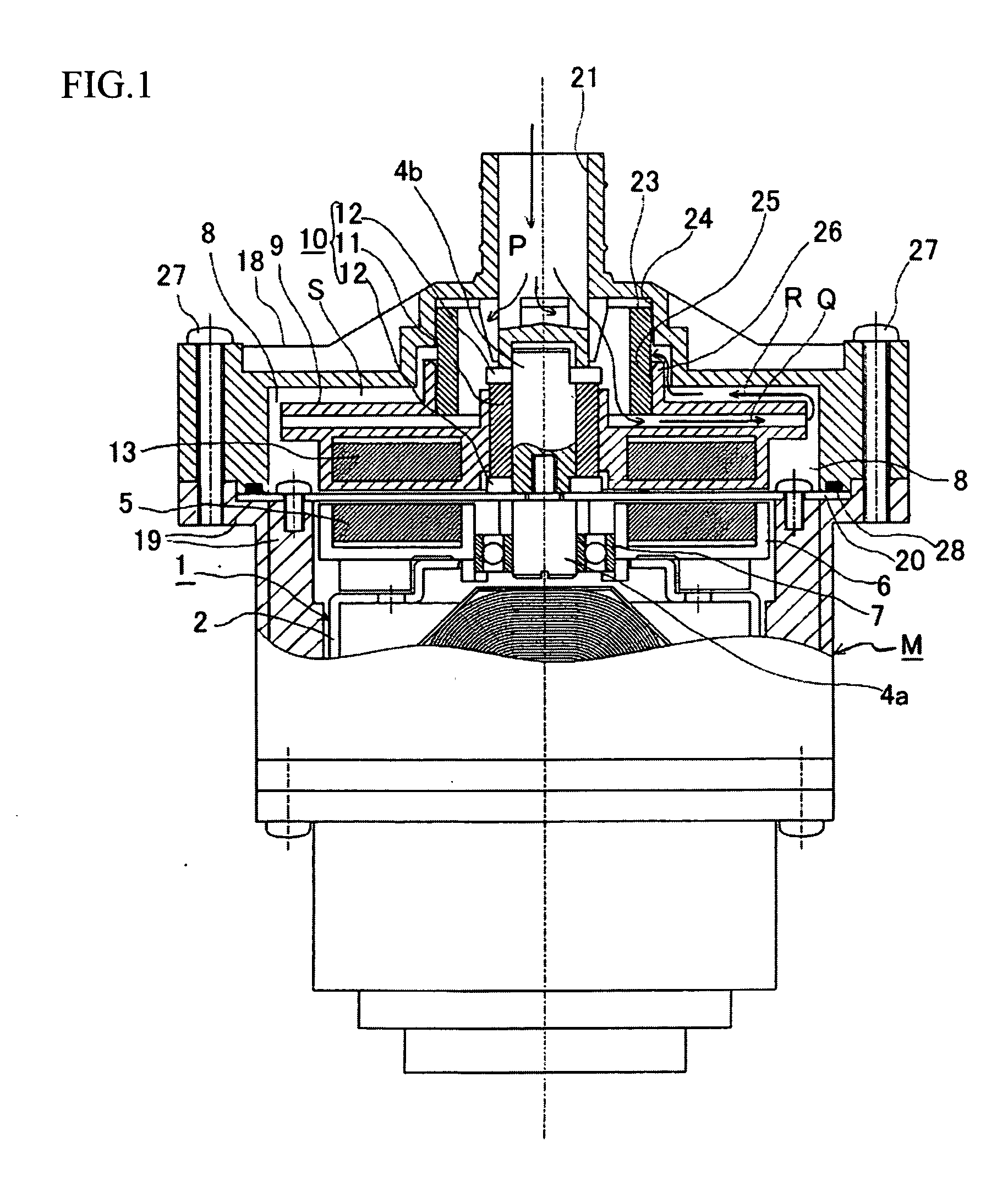

[0024]Preferred embodiments of the present invention will now be described in detail with reference to the attached drawings. First, the overall construction of a pump driving apparatus will be described with reference to FIG. 1 to FIG. 3.

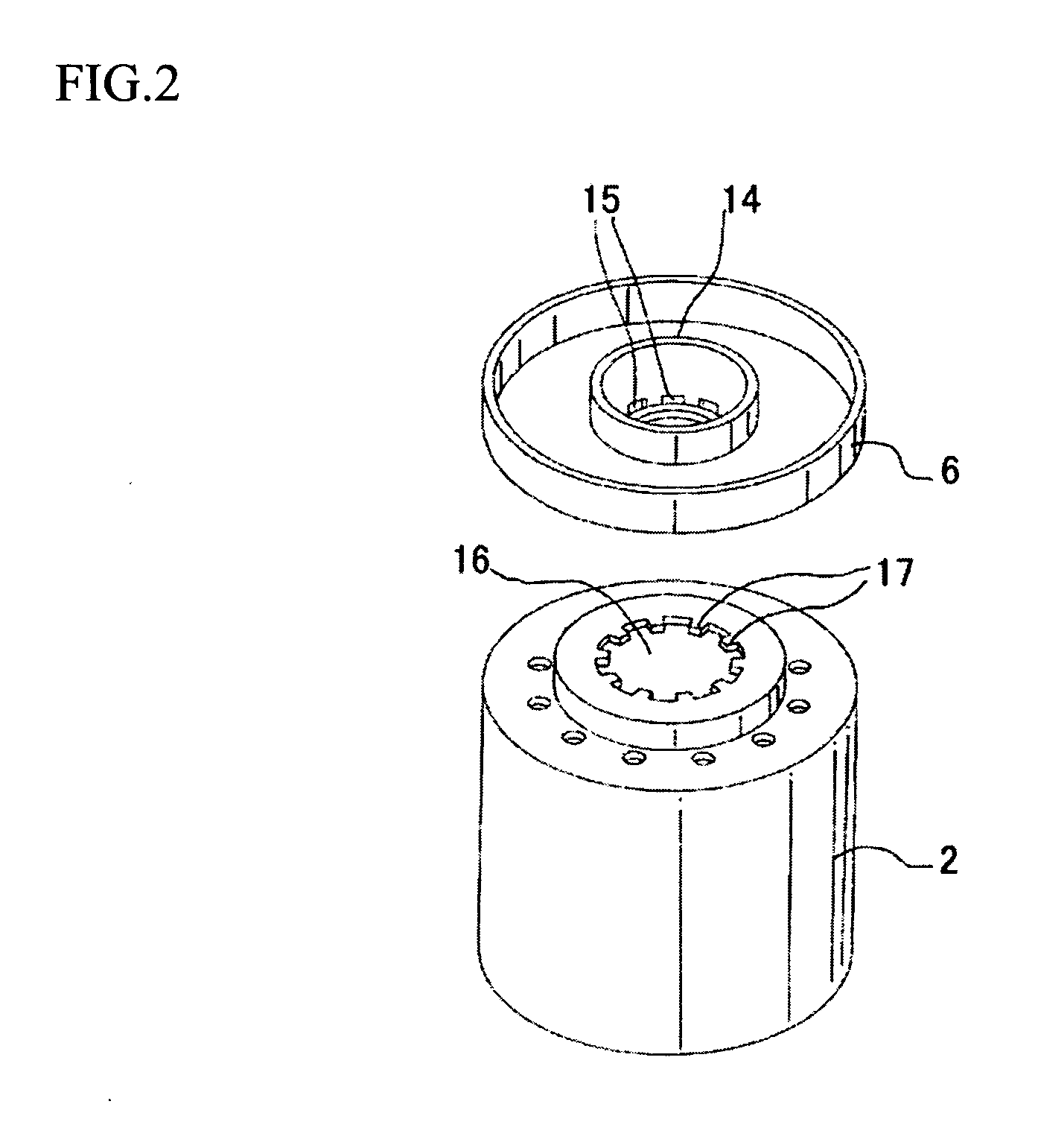

[0025]In FIG. 1, an example is shown where an outer-rotor, single-phase, bipolar brushless motor M is used as one example of a drive source for driving a pump. In this single-phase, bipolar brushless motor M, a rotor magnet (not shown) that is magnetized with two poles at 180° intervals is provided on a back yoke 2 of a rotor 1. The back yoke 2 is connected to a magnet case 6. A coupling magnet 5 is fitted into an upper surface of the magnet case 6. The magnet case 6 is rotatably fitted via a bearing 7 onto a motor-side fixed shaft 4a. Note that the rotor 1 is energized in the axial direction toward the magnet case 6 by a precompressed spring provided at a fixed end of the stator.

[0026]Here, the single-phase, bipolar brushless motor M is driven as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com