Automatic mounting machine for aluminum profile border corners

An automatic installation and aluminum profile technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity of manual work, change of seam gap between frames, and high production cost of products, so as to save manpower and ensure consistency Sexuality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

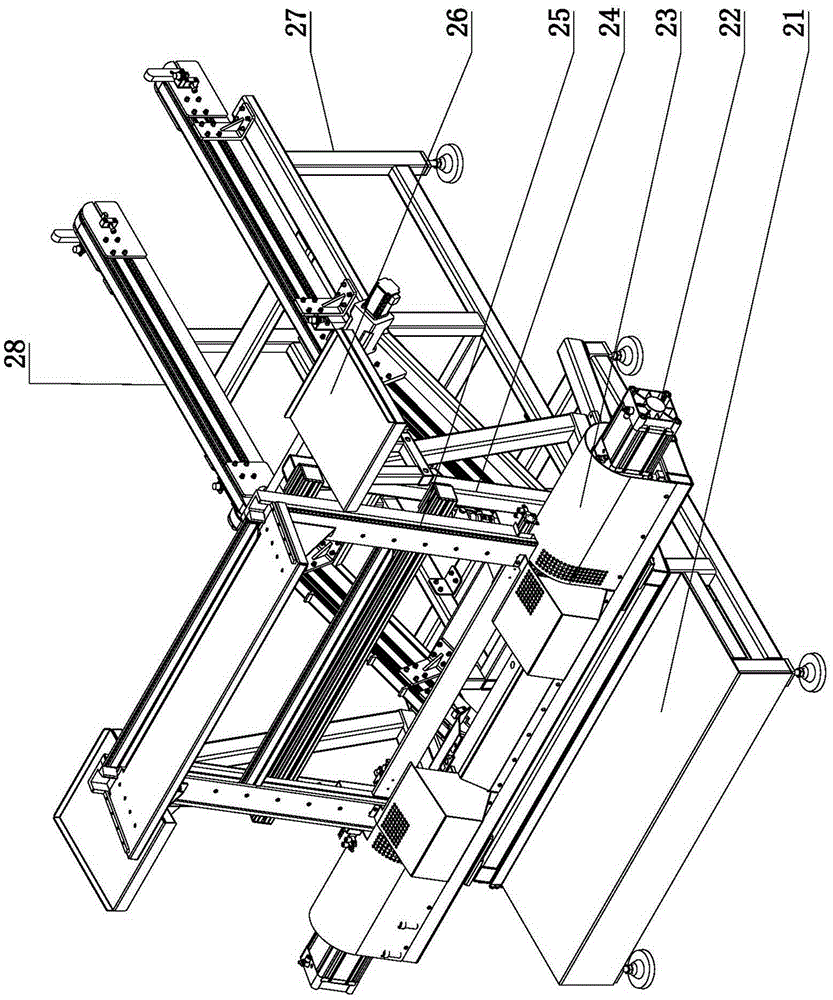

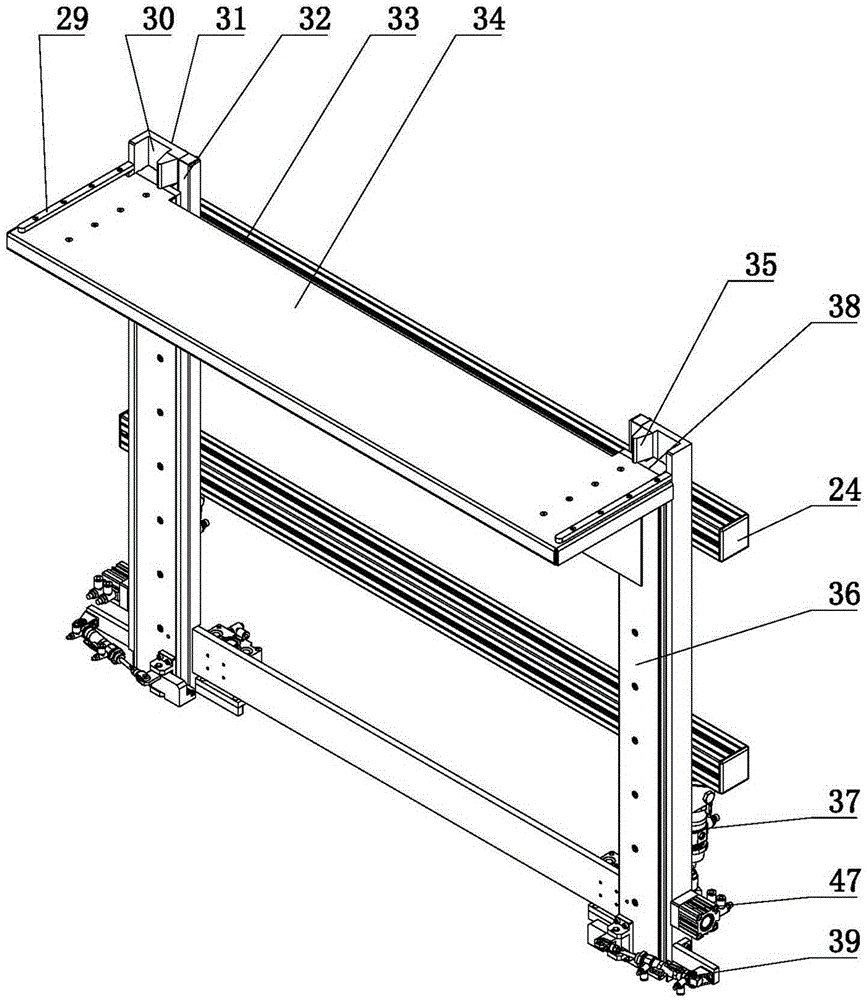

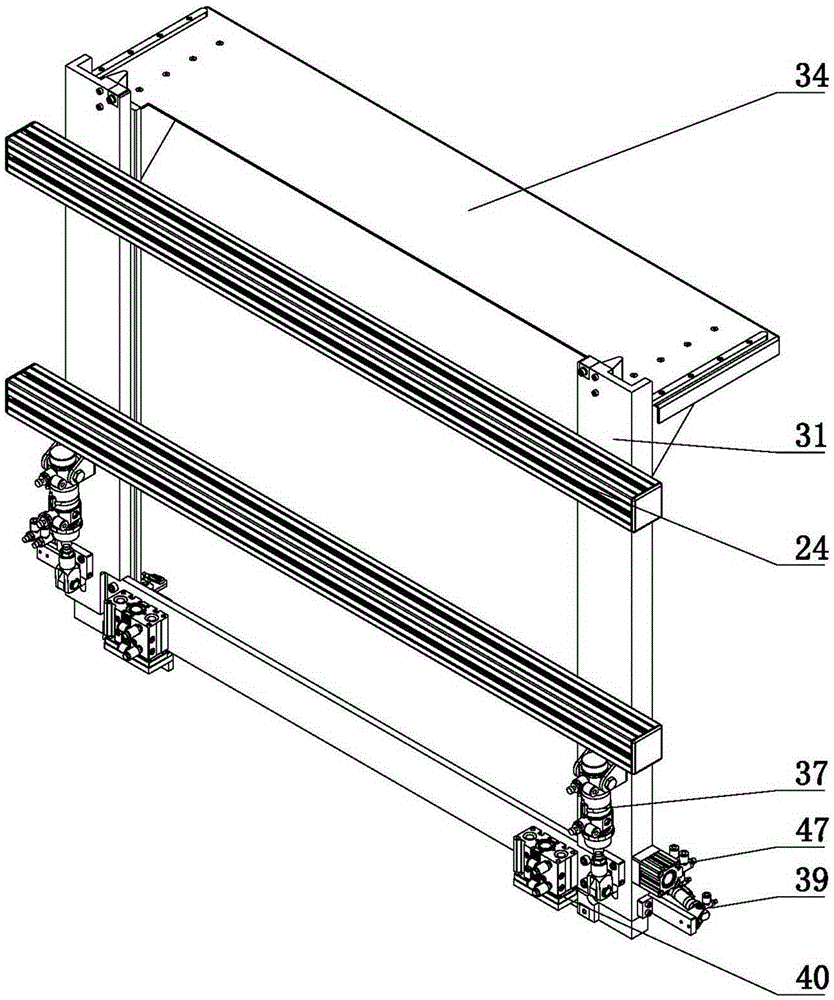

[0038] The present invention comprises feeding device 25 and pressure angle mechanism 22, is characterized in that: described feeding device 25 comprises frame 24, and frame 24 is provided with two silo columns 31; There is an upper material plate 34; the upper material upper plate 34 is provided with a frame lower trough 33 corresponding to the two silo columns 31, and the material bin column 31 is provided with a frame slideway 32 corresponding to the frame lower trough 33; Corresponding to the two ends of the feeding plate 34 on the storage bin column 31, a corner code slideway 30 is provided, and a corner code lower chute 38 is provided on the described feeding plate 34 corresponding to the corner code slideway 30; The lower end of the column 31 is provided with a frame unloading device 39 corresponding to the frame slideway 32; the lower end of the bin column 31 is provided with a corner code unloading device 37 corresponding to the corner code slideway 30; Corresponding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com