Storage cargo outlet method for storage rack and storage rack

A technology for storage racks and goods, which is applied in the field of box-packed goods and the field of storage racks, which can solve the problems of low automation, waste of storage space, and large volume of manipulators, so as to achieve controllable number of warehouses and improve The effect of warehouse-out speed and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

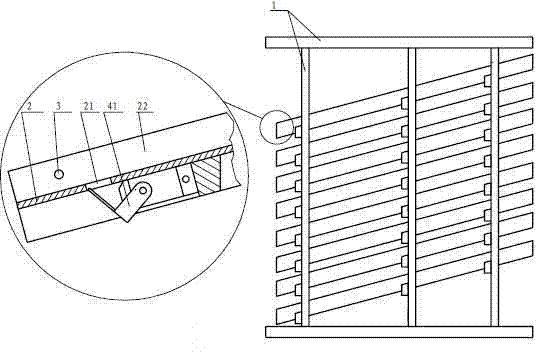

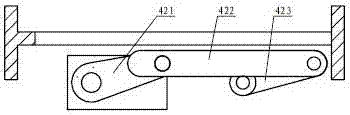

[0023] The invention relates to a method for releasing goods stored in a storage rack. The storage board used for shelving the goods is placed obliquely so that the surface of the storage board becomes an inclined plane, and a limiter for preventing the goods placed on the storage board from sliding down is set at the bottom of the inclined plane. position element, a lifting mechanism is set under the storage board 2, and a through hole 21 for the lifting mechanism to lift and reset is opened on the storage board 2, and then the goods are placed on the inclined storage board, and Arrange the goods one by one on the inclined surface formed by the inclined storage board above the limit element; when the goods need to be shipped, the lifting mechanism will first lift the goods to be released close to the limit element and make the goods higher than the limit element. The limiting element, under the action of the gravity of the goods above the inclined plane, the goods to be d...

Embodiment 2

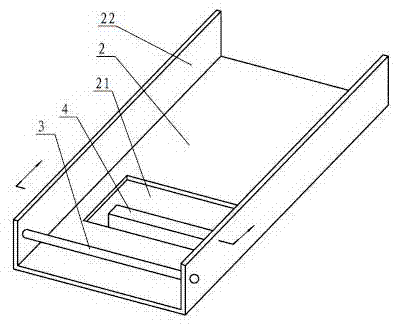

[0025] A storage rack used for storing goods in the storage rack, comprising: a bracket 1, a storage board 2 is connected to the bracket 1 and the storage board 2 is arranged obliquely, and a limit position is set on the storage board 2 Component 3 and the limiting element 3 are located at the downstream of the storage plate 2 which is inclined. The storage plate 2 is provided with a through hole 21 and the through hole 21 is adjacent to the limiting element 3. Below the through hole 21, there is a The cargo lifting mechanism, when the cargo to be shipped needs to be shipped, the lifting mechanism rises and lifts the cargo to be shipped. In this example,

[0026] A wing plate 22 is provided on the side of the storage board 2 .

[0027] The limiting element 3 is an object located on the sliding track of the storage on the storage plate, and its function is to block the sliding of the storage on the storage plate. Therefore, the limiting element 3 can be one of the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com