Horizontal-moving movable frame delivery device

A technology of horizontal movement and movable racks, which is applied in the field of logistics and warehousing, can solve the problems of increasing warehouse load, low degree of automation, and heavy adjustment workload, etc., and achieves a high-speed warehouse-out, controllable quantity of warehouse-out, and a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

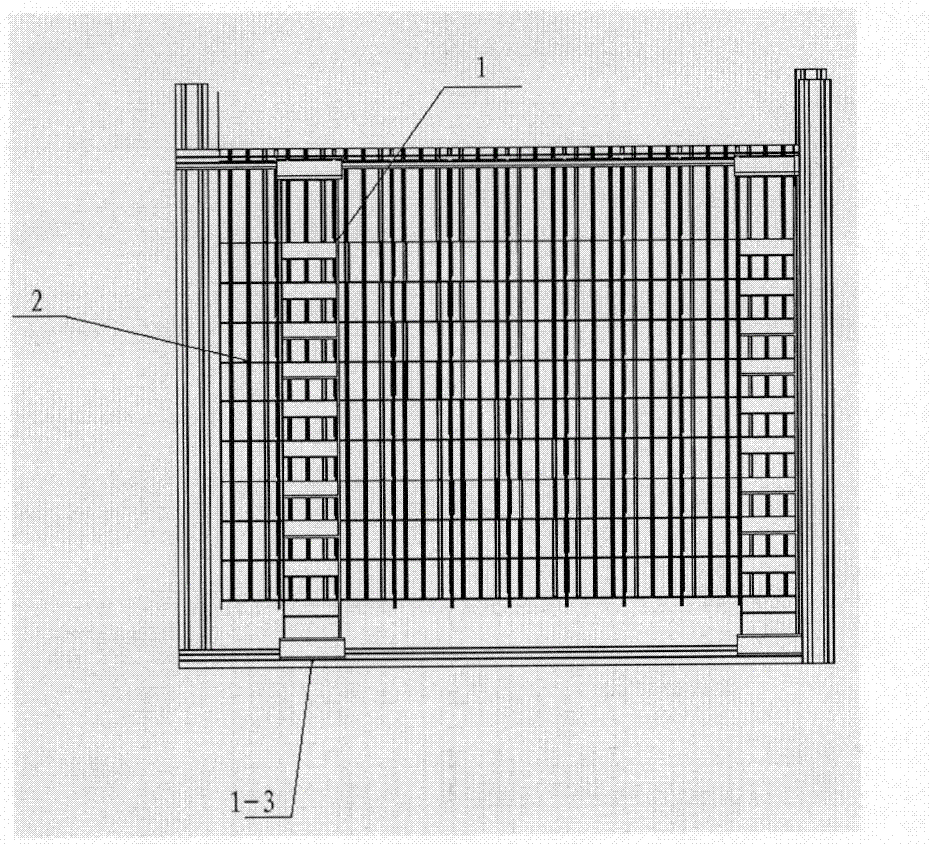

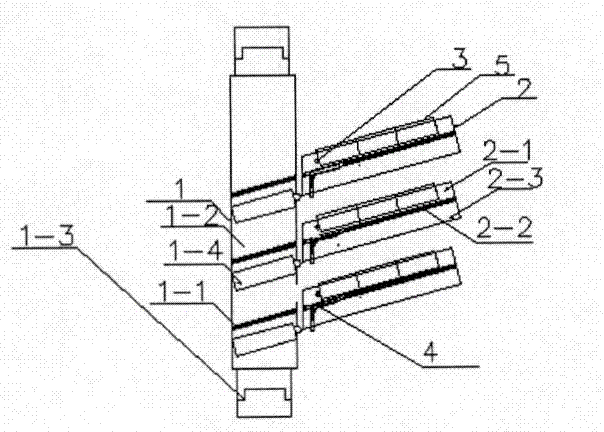

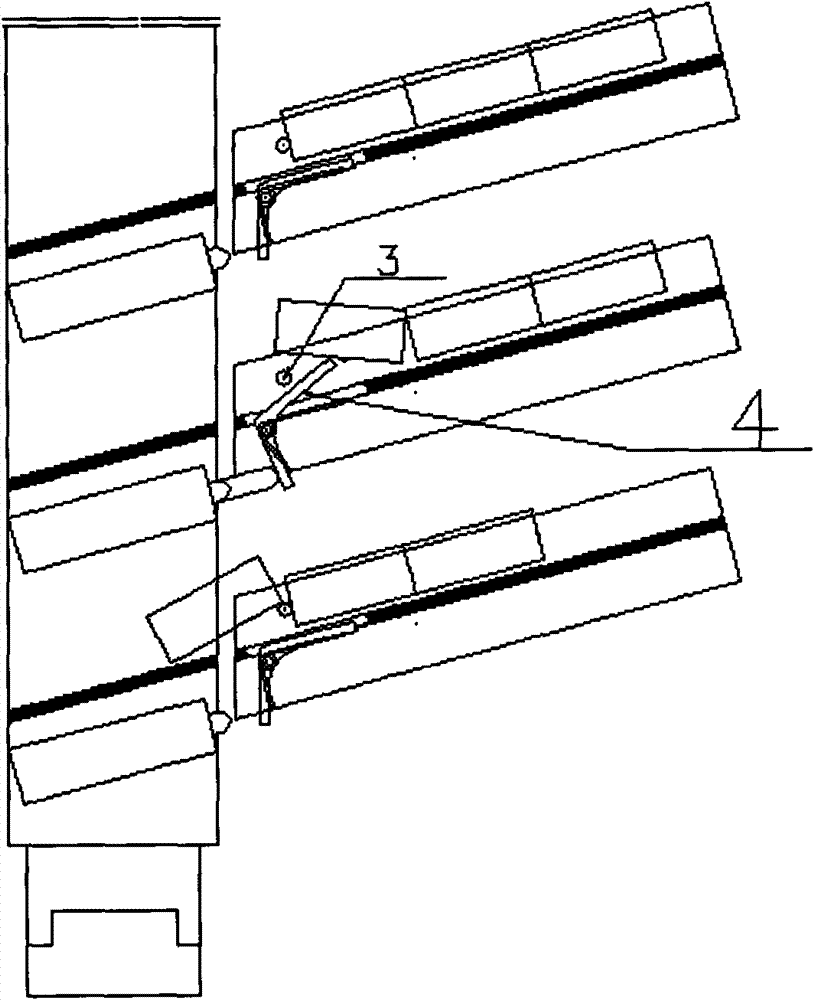

[0020] The fast movable frame 1 includes a frame 1-2 and a slide plate 1-1. The bracket is used to support the slide board and the power source, the guide rail is used to fix the fast movement of the bracket, the slide board provides a receiving and guiding function for the storage, and the power source is used to provide turning power for the reset part. The storage tank is composed of side plates, bottom plates and ribs 2-3, wherein the side plates play a position-limiting and guiding role, the bottom plate is used to carry goods 5, and the ribs are located below the bottom plate, which can strengthen the strength of the storage tank; A row of queues is formed in the storage tank; the storage tank is installed obliquely, and a fixed stopper is installed in front of the storage tank to prevent the storage from sliding out freely; the opening on the front bottom plate of the storage tank is equipped with a reset piece for storage. ejected.

[0021] combine figure 2 , imag...

Embodiment 2

[0024] The quick movable frame 1 includes a bracket 1-2 and a slide plate 1-1. When the cargo 5 is stored on the storage tank 2, the cargo 5 tends to slide due to gravity. At this time, the fixed block 3 plays a role in blocking the cargo 5 from sliding. In this embodiment, the power source 1-4 is a motor. The motor drives the "L"-shaped reset part 4 to turn over. When the power source 1-4 is working, the reset part 4 turns over under the action of the power source 1-4 to raise the storage 5. When the storage 5 is higher than the fixed stop At 3 o'clock, due to the effect of gravity, a piece of goods at the front of the storage queue slides out and falls onto the slide plate 1-1 of the fast movable frame 1. At this time, the motor drives the "L" shaped reset part 4 to turn over to restore it to its original position. position, the next storage item slides forward to the position of the fixed stopper 3 due to its own weight, and is blocked by the fixed stopper 3, so that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com