Vibratory discharge silo with central discharge hopper and discharge method

A technology for discharging hoppers and barrels, which is applied in the field of silos, which can solve the problems that the discharging process requires manual supervision, is easily corroded and damaged, and has high costs, and achieves the effects of avoiding structural defects, fast discharging speed, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

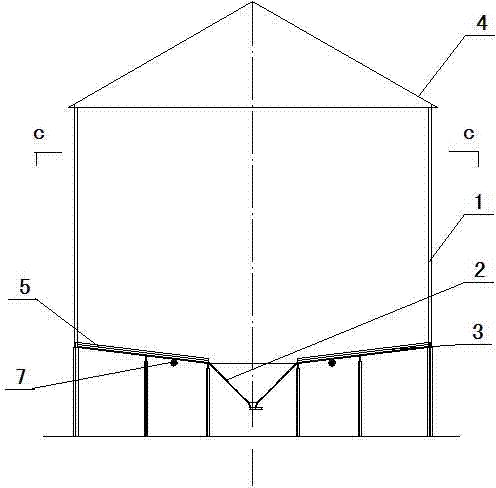

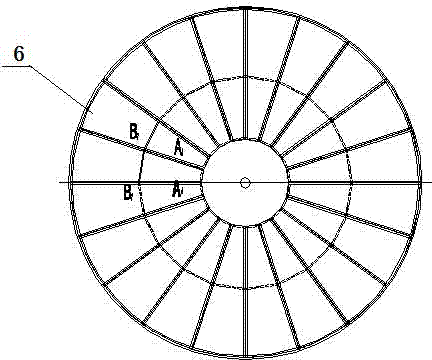

[0031] The vibrating unloading silo with a central discharge hopper is composed of: a silo body 1, a silo bottom 3 with a central gravity hopper 2 and a silo cover 4. A set of sloping installations around the central gravity hopper 2 The unloading tray 5, the disc 6 of the unloading tray 5 can be made into a fan-shaped, strip-shaped or polygonal shape, and the unloading tray is connected to a vibration source 7. The feeding tray is divided into 4-50 pieces according to the diameter of the silo body, mainly divided into sectors, which can be divided into several rings first, and then divided along the diameter.

[0032] The vibration source is a vibration motor, or an impact head driven by a pneumatic pump or a hydraulic pump, or an eccentric cam driven by a motor can be used to generate vibration.

Embodiment 2

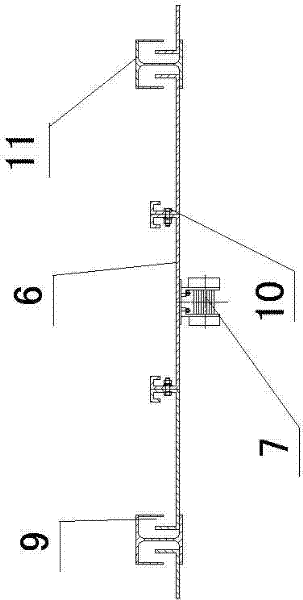

[0034] In the vibrating unloading silo with a central discharge hopper described in Example 1, a reset spring 8 is provided at the lower part of the lowering tray. The reset spring can be a leaf spring used in a car, or a tension spring or a compression spring. , The main function is to lift the disc to a certain distance from the bottom of the warehouse, which can reduce wear and facilitate vibration work.

Embodiment 3

[0036] In the above-mentioned vibration unloading silo with a central discharge hopper, the vibration source is a vibration motor or a cam structure connected to the motor, which generates bump vibration through the rotation of the cam or through the impact of a pneumatic piston or a hydraulic pulse piston. The vibration source of the environment where the warehouse is located can also be provided in other ways. The vibration motor is the best. It is confirmed by experiments that when the vibration source is installed on the side of the disc off the center of the gravity bucket , The effect is better, the following materials will speed up the flow rate and increase the flow during the process of collapse and self-flow. Generally, the vibration source can be installed on the downward side of the disc, which is convenient for maintenance and can avoid moisture erosion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com