Intelligent warehouse-out device applied to bottom of horizontal warehouse

A one-story warehouse, intelligent technology, applied in the field of intelligent warehouse, can solve the problems of showing bulk materials in the warehouse, low efficiency of manual warehouse delivery, low automation of warehouse delivery, etc., to ensure operation safety, improve later operation accuracy, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

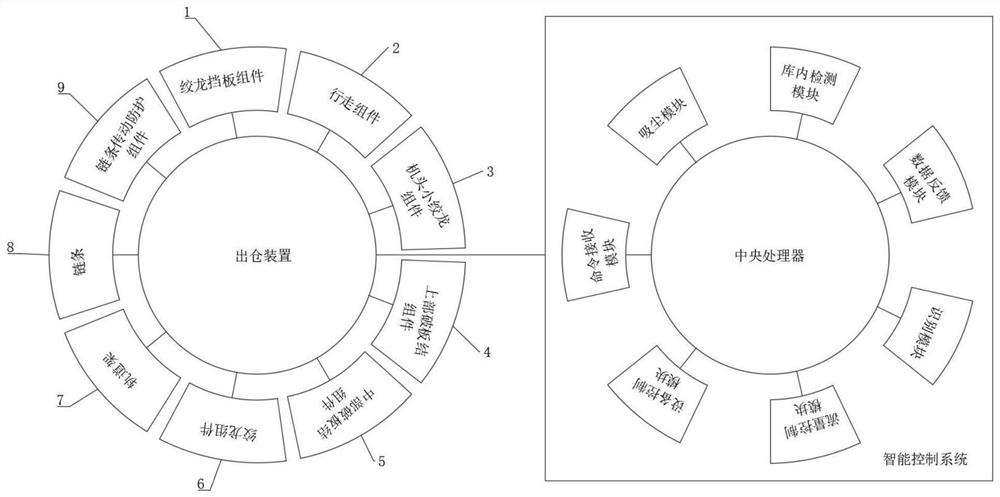

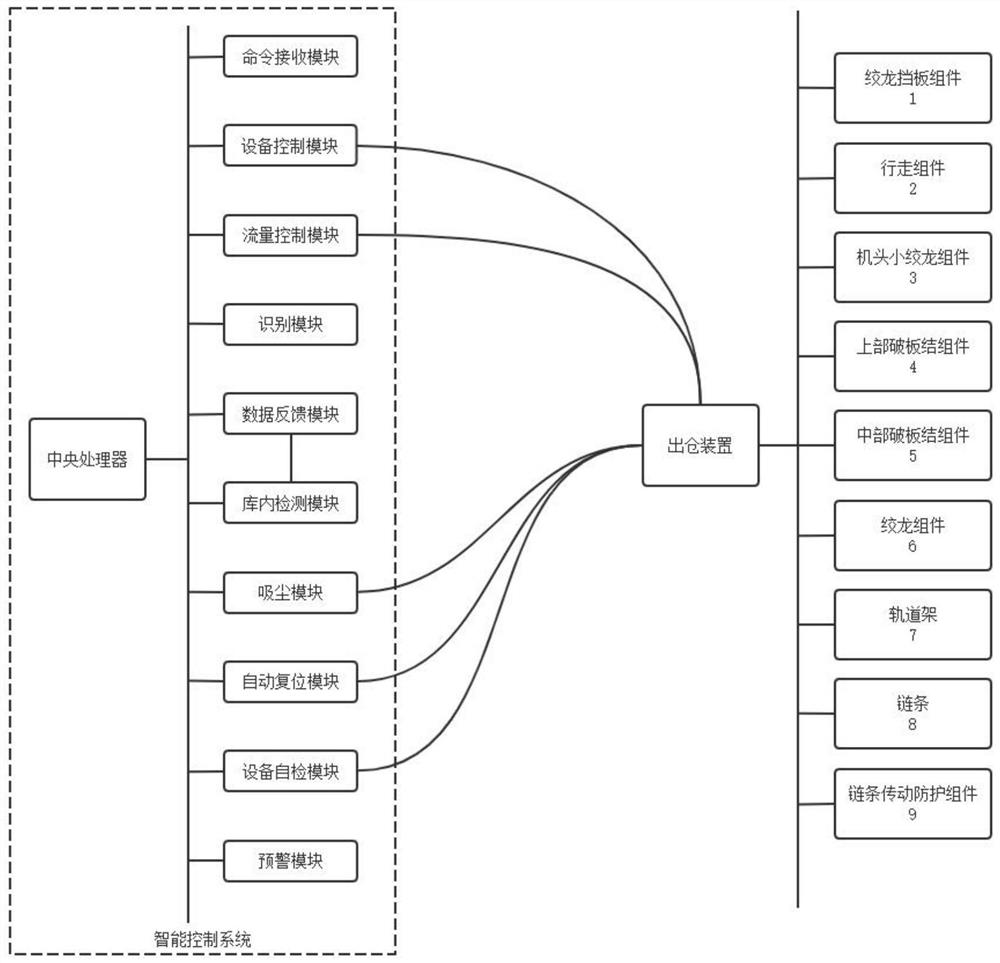

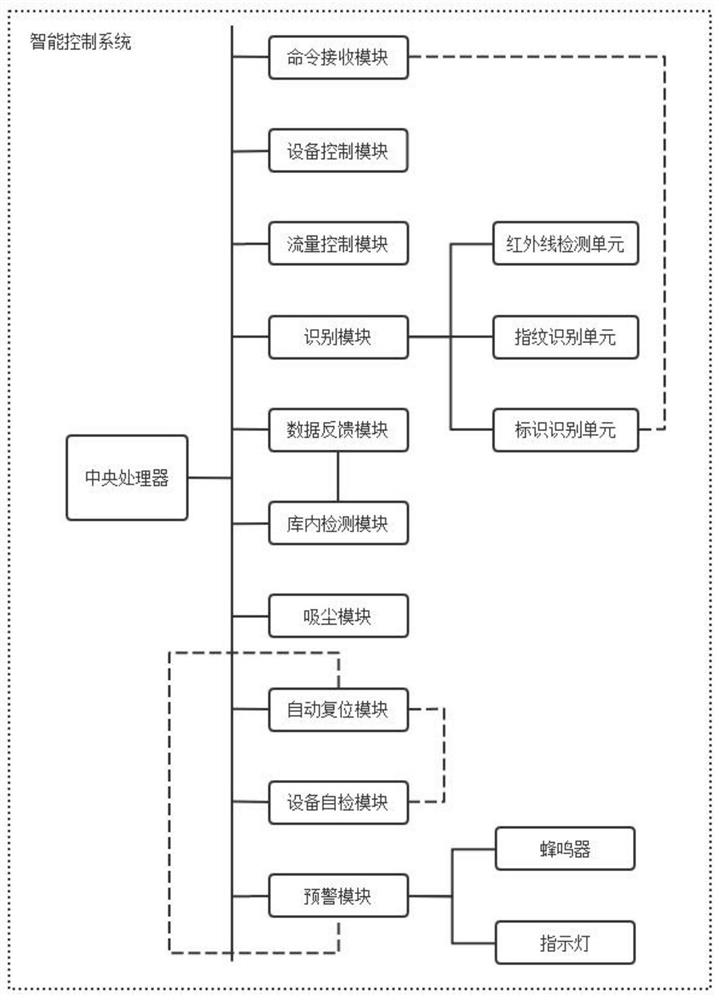

[0062] see Figure 1-10 , an intelligent warehouse-out device applied to the bottom of a bungalow warehouse, including a warehouse-out device, the warehouse-out device includes a mutually matching auger baffle assembly 1, a walking assembly 2, a small auger assembly 3 at the machine head, and an upper broken board assembly 4. The broken plate knot assembly 5 in the middle, the auger assembly 6, the track frame 7, the chain 8 and the chain transmission protection assembly 9, and an intelligent control system is provided on the warehouse-out device. The intelligent control system includes a central processing unit connected to a The command receiving module, equipment control module, flow control module, identification module, data feedback module, detection module in the warehouse and dust collection module, the central processing is fixedly installed on the warehouse-out device, and the equipment control module and flow control module are connected through wires and strands. D...

Embodiment 2

[0069] see Figure 1-10 , wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 are described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 4 , the method of using the central processor to control the self-inspection of the warehouse-out device:

[0070] S1. After the central processor receives the bulk material out-of-warehouse data, it pre-starts the equipment self-inspection module;

[0071] S2. Control each component of the warehouse-out device through the equipment self-inspection module to conduct a trial run, and detect the operating status;

[0072] S3. When the equipment self-inspection module detects that the operating status of each component of the warehouse-out device is normal, the data is fed back to the central processing unit, and the warehouse-out device completes t...

Embodiment 3

[0075] see Figure 1-10, where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 5 , the central processor controls the use of the warehouse-out device for self-resetting:

[0076] S1. After the central processor receives the information fed back from the flow control module and judges that the bulk material has been discharged from the warehouse, it starts the automatic reset module to control the warehouse discharge device to perform self-resetting;

[0077] S2. Check whether the warehouse-out device has run to the initial position through the equipment self-inspection module;

[0078] S3. When the equipment self-inspection module detects that the warehouse-out device returns to the initial position, the data is fed back t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com