Tuned mass damper for controlling vertical high-frequency vibration of floor slabs and manufacturing method thereof

A technology for tuning mass damping and high-frequency vibration. It is applied in building components and anti-vibration. It can solve the problems of high height and difficult to install inside the floor, poor device durability, and inability to completely separate the damping and stiffness of damping components, so as to improve the starting characteristics. And the effect of durability, material saving and reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

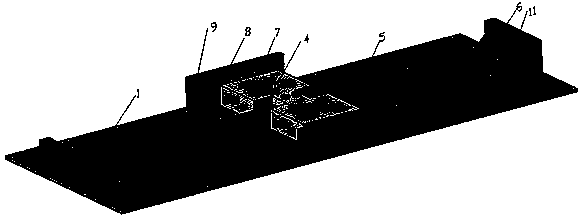

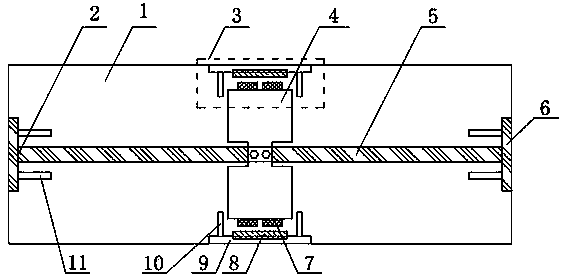

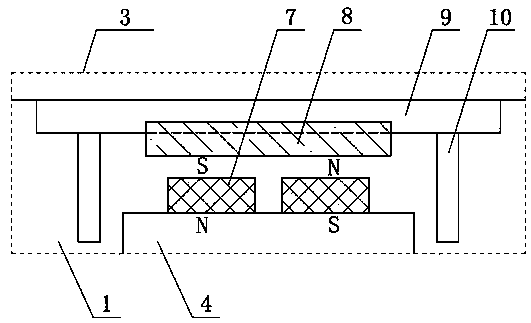

[0035] Example one, see Figure 1 to Figure 3, the present invention includes a portal rigid frame 2 , an eddy current damper 3 and a mass 4 . The portal frame 2 consists of a horizontal steel beam 5 and columns 6 fixed at both ends of the horizontal steel beam 5. The portal frame 2 is fixed on the concrete floor 16 through the base plate 1, and the mass block 4 is fixed on the portal frame 2 through bolts. At the middle position of the horizontal steel beam 5; the eddy current damper 3 is provided with two sets, each set consists of a pair of rectangular permanent magnets 7 installed on the mass block 4 with the N and S poles staggered and a vertical permanent magnet 7 welded on the bottom plate 1. The steel plate 9 and the conductor copper plate 8 installed on the inner surface of the vertical steel plate 9 are formed. The conductor copper plate 8 is thin in the middle along the vertical direction, and the upper and lower ends are thickened, which is equal to the net distanc...

Embodiment 2

[0049] Example 2, see Figure 5 The difference between this embodiment and the first embodiment is that the bottom plate in this embodiment is a cross steel plate, which can reduce the proportion of the non-moving mass of the tuning mass damper, which is suitable for when the tuning mass damper is installed above or below the floor slab, That is, top-mounted installation or suspension-type installation, other contents are the same as those in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com