Dynamic load simulating device and method for automobile power system test

A power system and dynamic load technology, which is applied in the field of dynamic load simulation devices, can solve problems such as long cycle period, difficult to accurately measure speed differential, and large size of flywheel group, so as to improve dynamic stability, shorten development cycle, and simulate accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

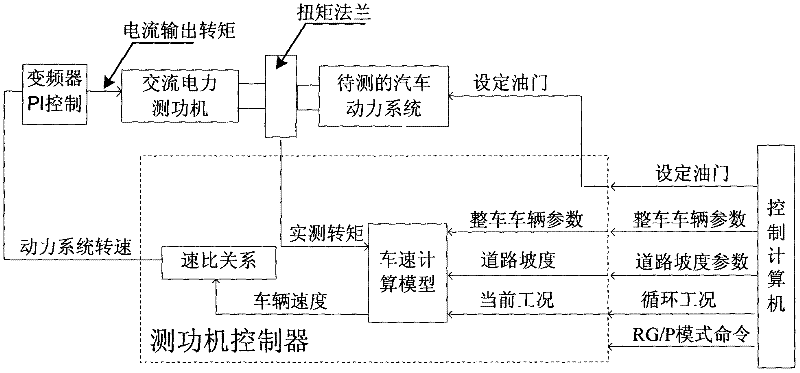

Embodiment 1

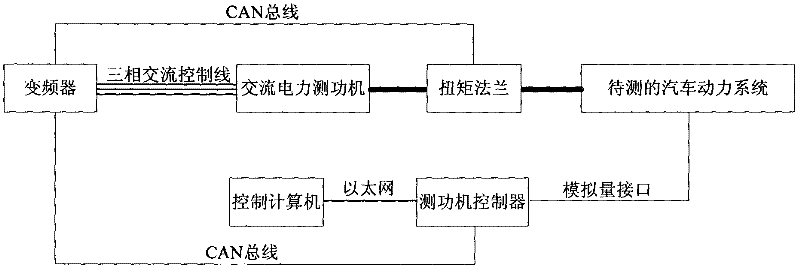

[0043] A dynamic load simulator for automotive powertrain testing, such asfigure 1 As shown, it includes a control computer, a dynamometer controller, a frequency converter, an AC power dynamometer and a torque flange with a controller, and its peripheral equipment is the vehicle power system to be tested;

[0044] The vehicle power system to be tested includes engine, clutch and transmission;

[0045] The power output shaft of the vehicle power system to be tested is connected to the power shaft of the AC power dynamometer through a torque flange with a controller; the inverter and the AC power dynamometer are connected through a three-phase AC control line; the frequency converter and the dynamometer The machine controller and the torque flange with the controller are connected through the CAN bus; the control computer and the dynamometer controller are connected through Ethernet; connected to the analog output port used to simulate the throttle;

[0046] The above-mentione...

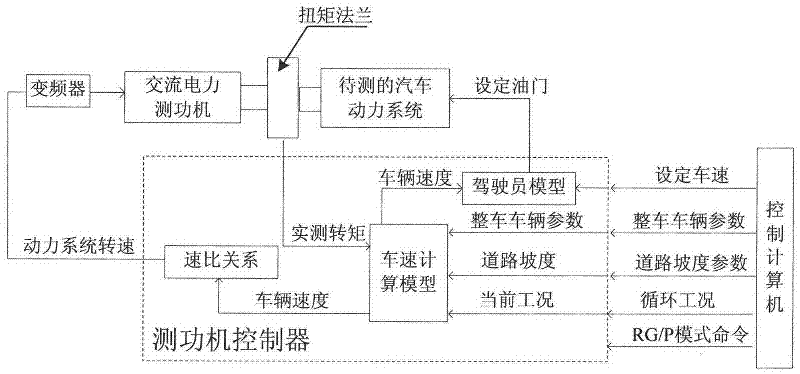

Embodiment 2

[0065] A dynamic load simulator for automotive powertrain testing, such as figure 1 As shown, it includes a control computer, a dynamometer controller, a frequency converter, an AC power dynamometer and a torque flange with a controller, and its peripheral equipment is the vehicle power system to be tested;

[0066] The vehicle power system to be tested includes engine, clutch and transmission;

[0067] The power output shaft of the vehicle power system to be tested is connected to the power shaft of the AC power dynamometer through a torque flange with a controller; the inverter and the AC power dynamometer are connected through a three-phase AC control line; the frequency converter and the dynamometer The machine controller and the torque flange with the controller are connected through the CAN bus; the control computer and the dynamometer controller are connected through Ethernet; connected to the analog output port used to simulate the throttle;

[0068] The above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com