In-situ monitoring fidelity continuous coring tool for horizontal well

A horizontal well, in-situ technology, applied in the direction of extracting undisturbed core devices, measurements, boreholes/well components, etc., can solve problems such as inapplicability, and achieve the effect of core fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

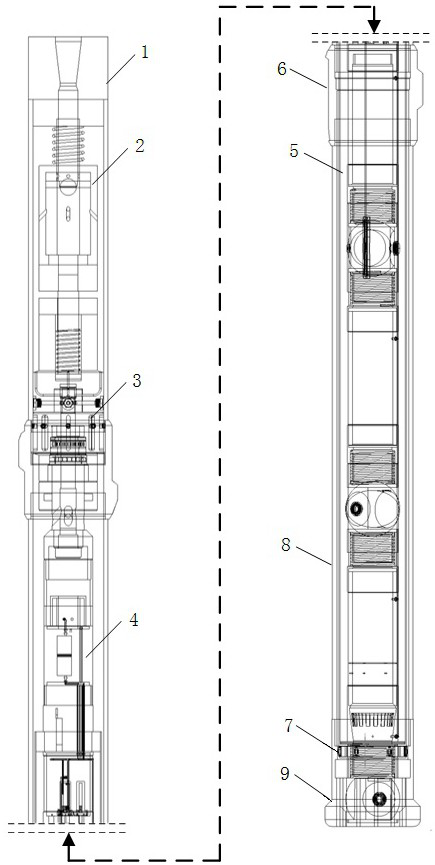

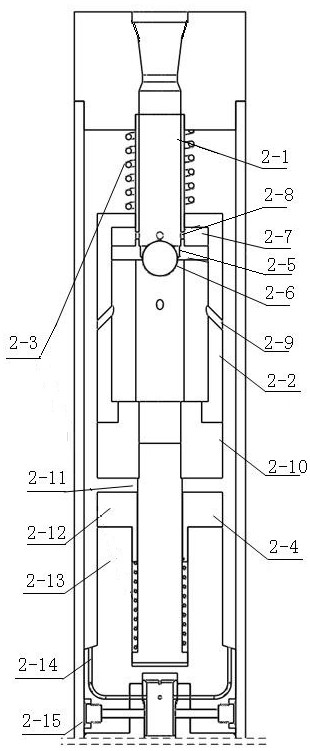

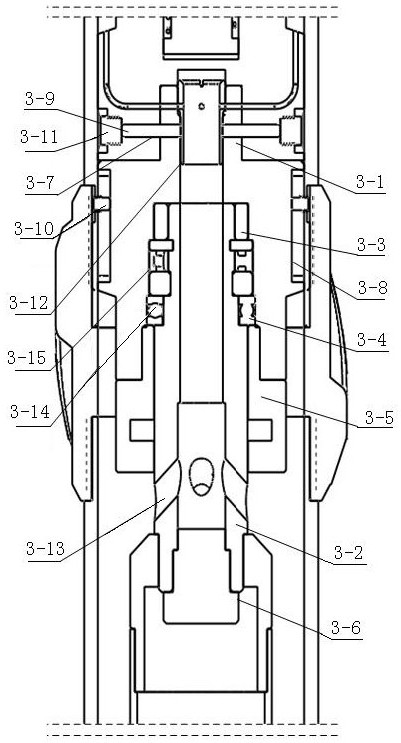

[0035] Such as figure 1 As shown, this horizontal well in-situ monitoring fidelity continuous coring tool includes a safety assembly 1, a hexagonal differential anti-lift mechanism 2, a suspension rotation assembly 3, an in-situ fidelity intelligent control assembly 4, and a storage inner cylinder assembly 5. Lower outer centralizer 6, inner cylinder centralizer 7, outer cylinder 8, core bit 9. Among them, the safety assembly 1, the outer cylinder 8, the lower outer centralizer 6, and the core bit 9 are fixedly connected in sequence to form the outer cylinder assembly, the six-way differential anti-lifting mechanism 2, the suspension rotation assembly 3, and the in-situ intelligent control assembly 4. The storage inner cylinder assembly 5 is fixedly connected in turn to form the inner cylinder assembly. The upper part of the safety assembly 1 is provided with a safety mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com