Line pressing machine for corrugated carton production

A corrugated box and wire press technology, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as adjusting the wire pressing knife, reducing the wire pressing efficiency of the wire pressing machine, and reducing the pressing quality of the wire pressing machine. , to achieve the effect of improving the crimping efficiency, preventing edge warping and improving crimping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

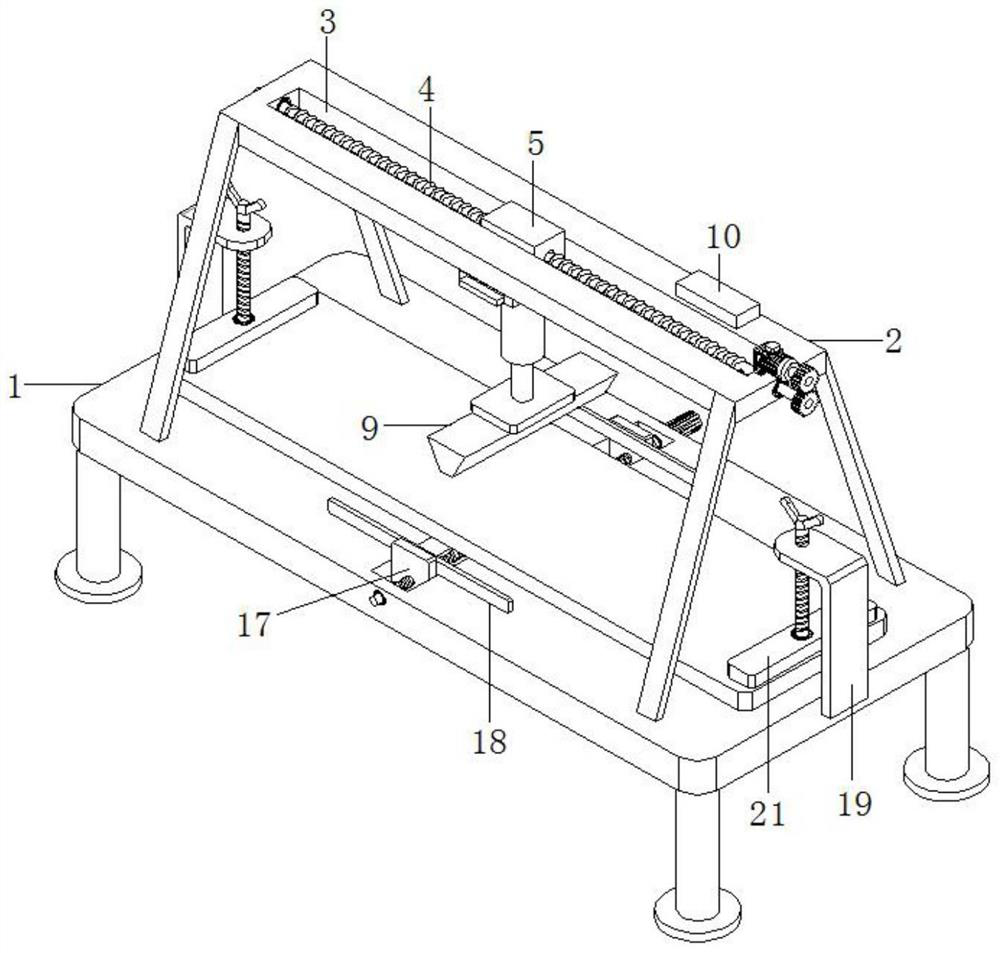

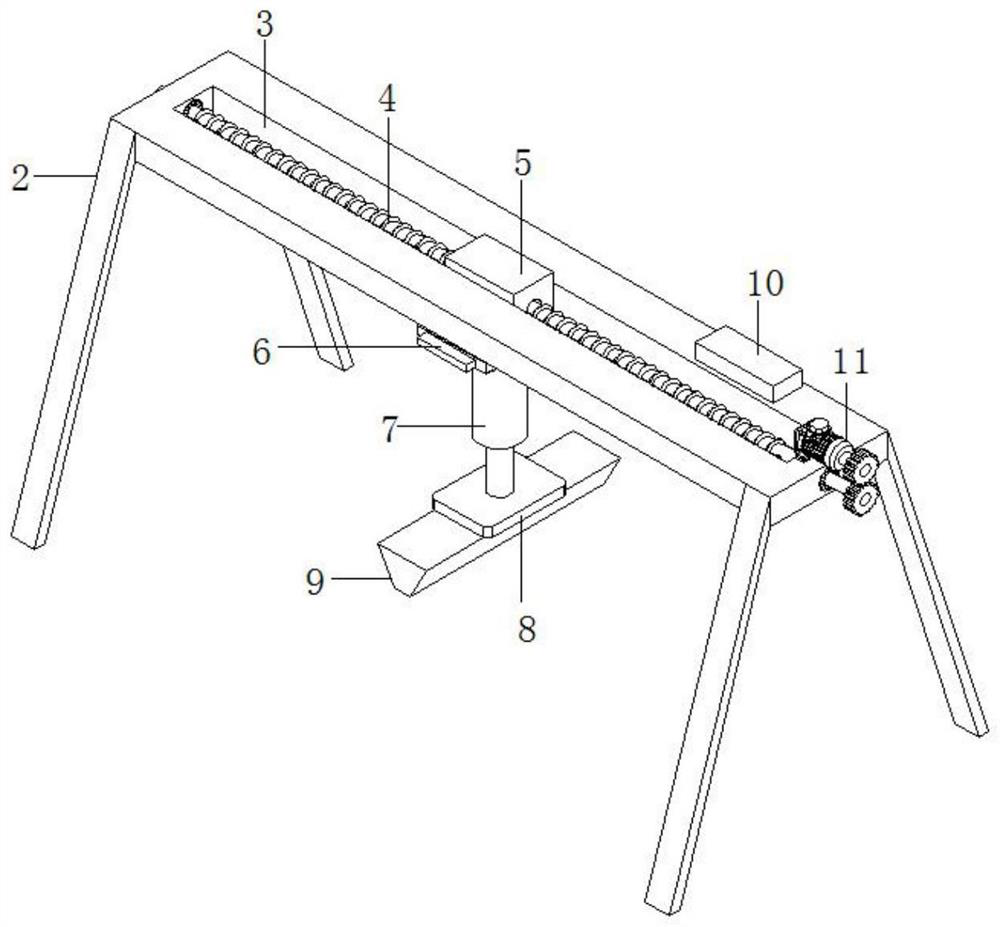

[0023] Example 1, refer to Figure 1-4 , a corrugated box production line press, including a processing table 1, a frame 2 and an adjustment mechanism;

[0024] The frame 2 is welded to the top outer wall of the processing table 1, and the adjustment mechanism is specifically composed of a slideway 3, a lead screw 4, a T-shaped slider 5, an infrared sensor 6, a pressing component and a control component;

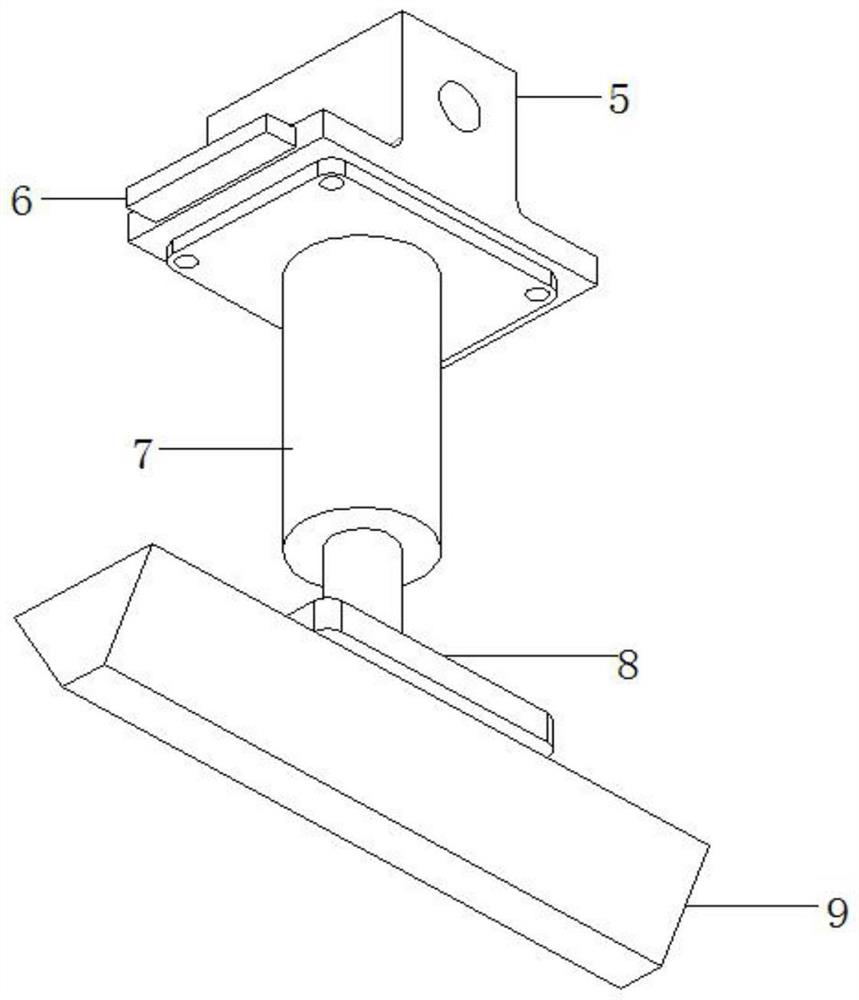

[0025] The slideway 3 is opened on the top of the frame 2, the lead screw 4 is connected to the inner walls on both sides of the slideway 3 through two bearings, the T-shaped slider 5 is screwed to the middle of the lead screw 4, and the infrared sensor 6 is connected by screws On the front outer wall of the T-shaped slider 5;

[0026] The outer wall of the T-shaped slider 5 is slidably connected with the inner wall of the slideway 3, which is convenient for the movement of the T-shaped slider 5 to be well limited. 9, the control assembly is specifically composed of a micr...

Embodiment 2

[0030] Example 2, refer to figure 1 and Figure 5 , This embodiment is optimized on the basis of Embodiment 1, specifically: a corrugated box production line press, also comprising two anti-warping mechanisms and a righting mechanism;

[0031] The centralizing mechanism is specifically composed of a chute 14, a servo motor 15, a bidirectional screw 16, two movable blocks 17 and two centralizing plates 18. The two anti-warping mechanisms are both composed of an L-shaped plate 19, a butterfly-shaped screw Block 21 consists of;

[0032] Through the cooperation of the righting mechanism and the two anti-warping mechanisms, the corrugated cardboard that is placed inclined is easy to be righted, and the two sides of the corrugated cardboard can be easily pressed after the righting is completed, thereby preventing the occurrence of warping during the pressing process. In this way, the crimping quality of the entire crimping machine can be improved;

[0033] The chute 14 is opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com