Centering adjusting device for top-drive guide rail

A technology of adjusting device and top drive guide rail, which is applied in the field of guide rail to achieve the effect of simple structure, convenient installation and disassembly, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is further described:

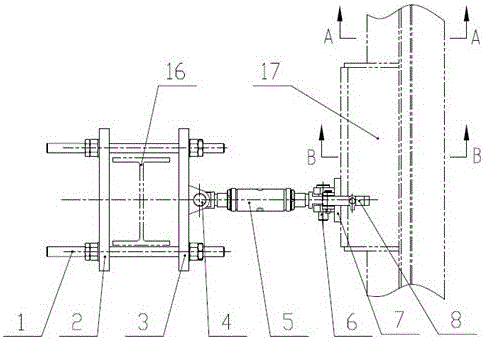

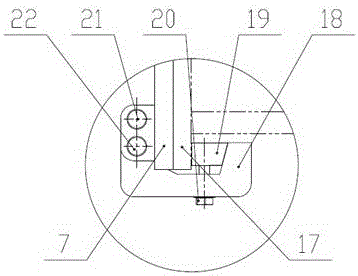

[0022] Such as figure 1 As shown, a top drive guide rail righting adjustment device includes a derrick beam 16 and a guide rail 17, the pressure plate 2 and the connecting seat 3 are connected by a stud 1 and clamped to the derrick beam 16; the first pin shaft 4 is arranged horizontally and simultaneously Connect the connecting seat 3 and the adjusting screw 5, and the other end of the adjusting screw 5 passes through the second pin shaft 6 arranged vertically and the adjusting lug 7 (for details, see Figure 5 ) is connected in the middle, and the two ends of the adjusting ear seat 7 are clamped and connected with the guide rail 17 by the clamping device 8 .

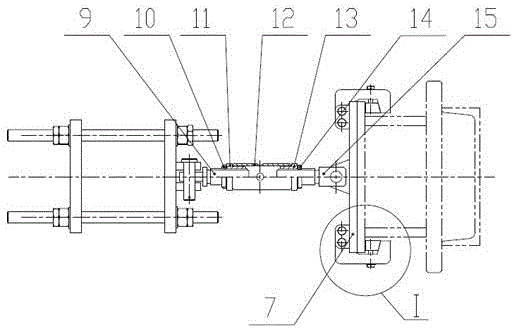

[0023] Such as figure 2 As shown, the adjusting lead screw 5 is composed of a thick lead screw, a lock nut 10, a weld nut 11, an intermediate pipe 12, a left-hand weld nut 13, a left-hand lock nut 14 and a left-hand t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com