Automatic line-cross device for seats

A seat, automatic technology, applied in the direction of lifting device, hoisting device, transportation and packaging, etc., can solve the problems of weight concentration, difficult to achieve precise adjustment, complex structure, etc., to improve efficiency, ensure integrity, and improve operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

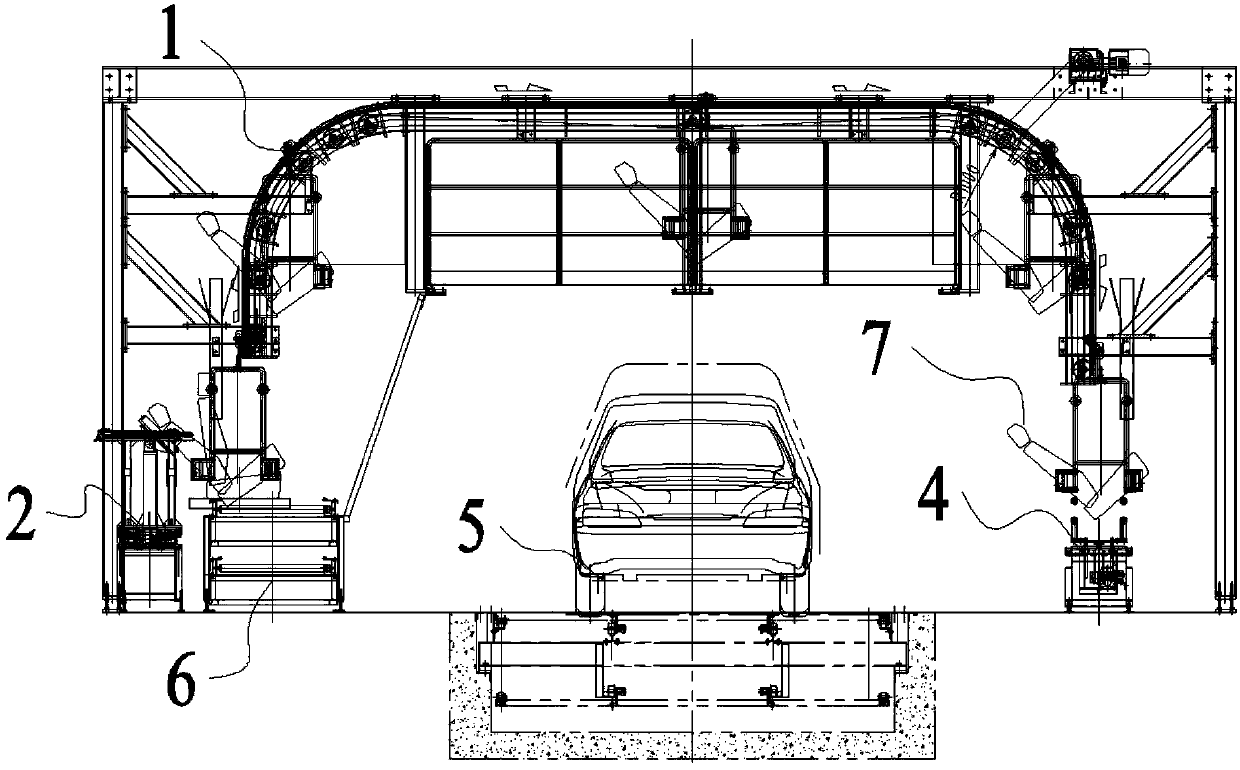

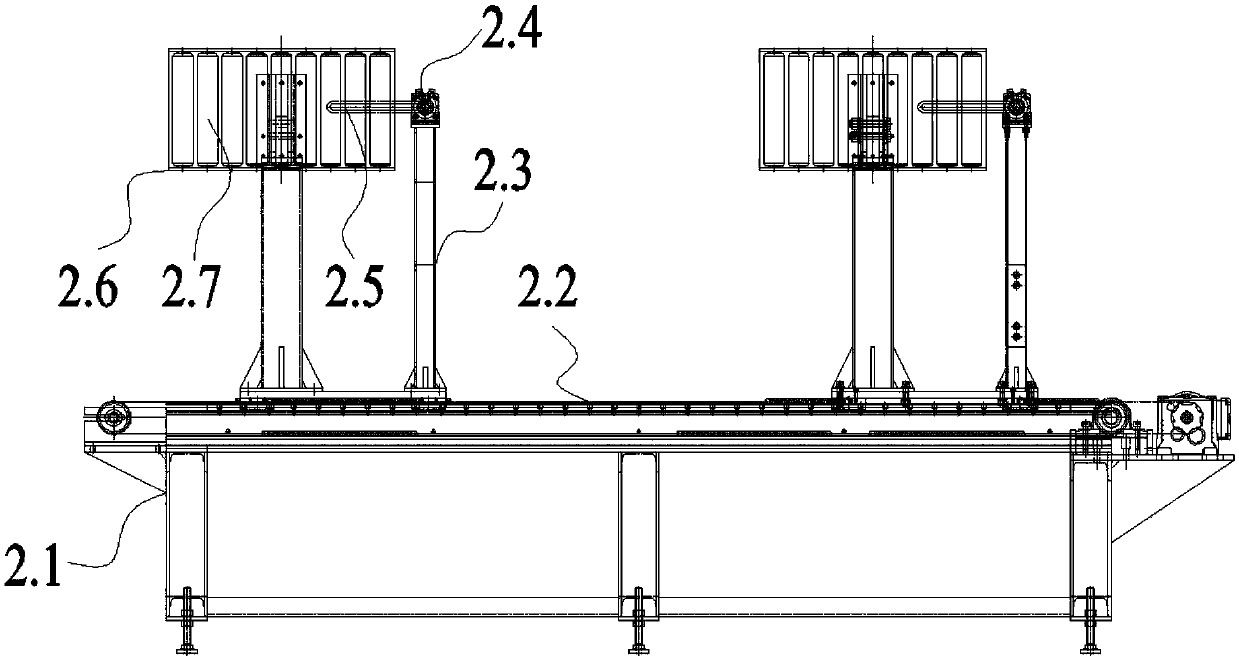

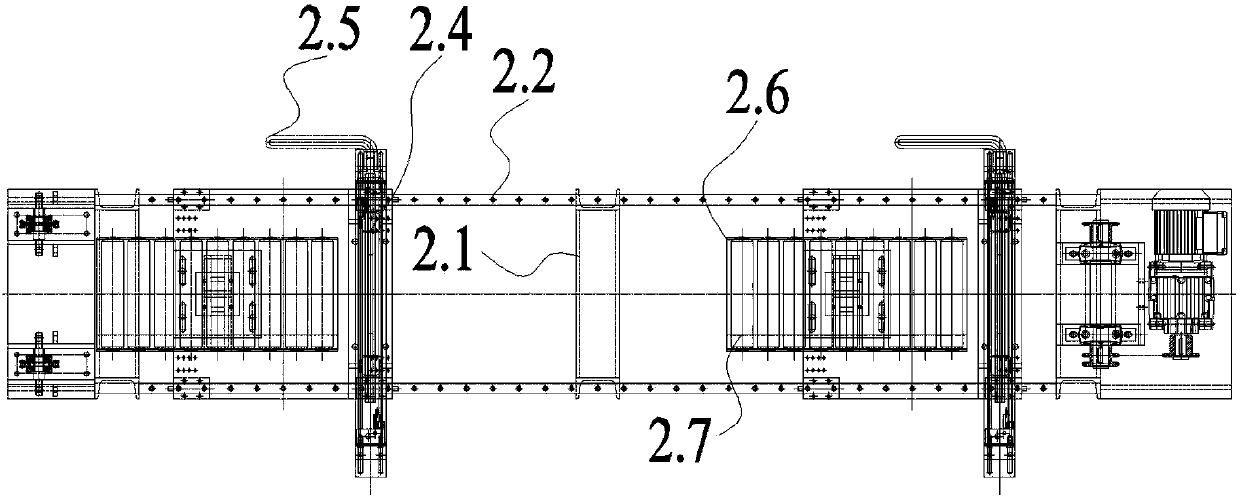

[0039] like Figure 1-9 , an automatic seat crossing device, an assembly line 5 is arranged on both lateral sides in turn with an overturning device 2 and a righting device 3 , and a transplanter 1 is installed above the assembly line 5 . The transplanter 1 is used to move the seat 7 from the first lateral side of the assembly production line 5 to the second lateral side; Pull it down to make it vertically rotate and offset an angle; the righting device 3 is located on the second lateral side of the assembly line 5 and is used to push the seat 7 in a tilted deflection state to make it stand upright. The lateral direction of this embodiment figure 1 In the left and right direction, vertical refers to the vertical figure 1 The direction of the drawing, the up and down direction refers to figure 1in the up and down direction.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com