Drill rod centralizer

A technology for centralizers and drill pipes, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., which can solve the problems of high labor costs and low applicability, and achieve the effects of reducing labor costs, wide application range, and saving disassembly and assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

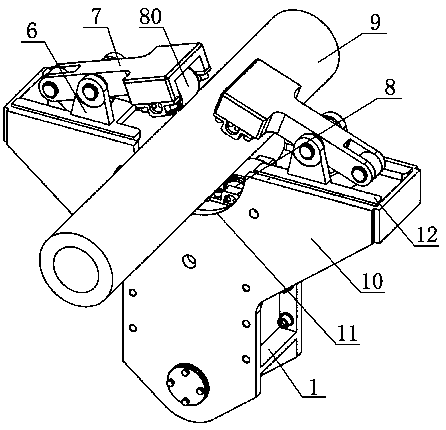

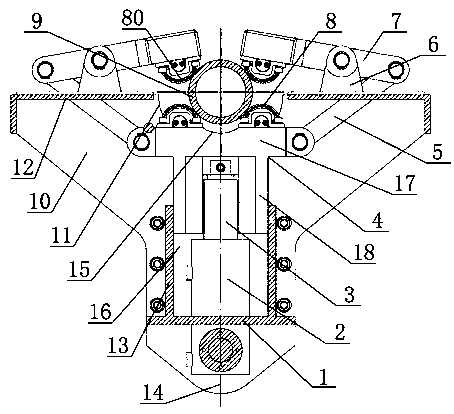

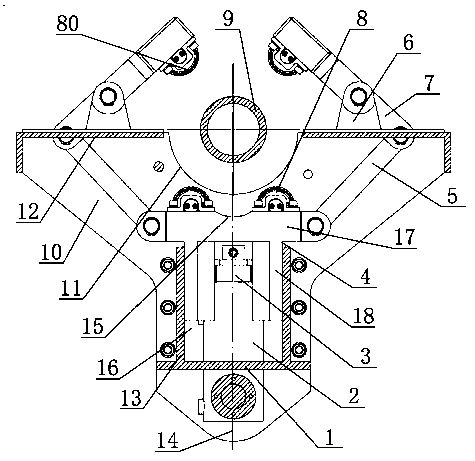

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0034] like figure 1 As shown, the upper end of the base 1 of the present invention is open and the lower end is closed. The height is less than the height of the vertical plate 10, and the top surface of the baffle plate 13 has a certain distance from the top of the vertical plate 10, and the bottom plate of the base 1, the vertical plate 10 and the baffle plate 13 encircle an internal cavity 16 with an upper opening; the vertical plate The center of the upper end of 10 is provided with a semicircular first opening 11. The first opening 11 is recessed, which can avoid interfering with the drill pipe 9 during straightening, and scratch the outer surface of the drill pipe 9. At the same time, the first opening 11 can also avoid damage to other parts because the drill rod 9 outer diameter is too large. like figure 2 As shown, an oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com