Preparation for feather keratin membrane and use of feather keratin membrane as medicament carrier

A keratin and drug technology, applied in the polymer field, can solve the problems of unstable structure, unsuitable for injection drug, low drug loading rate, etc., and achieve the effects of good mechanical properties, low cost, and easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

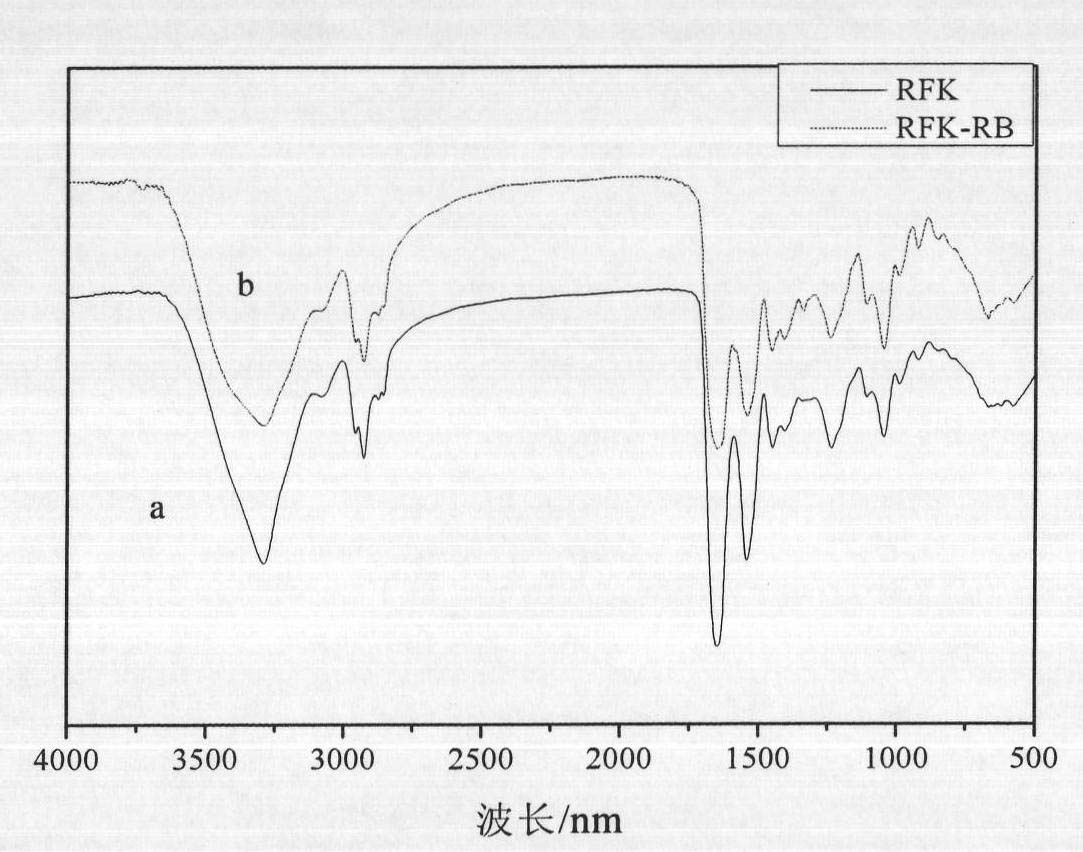

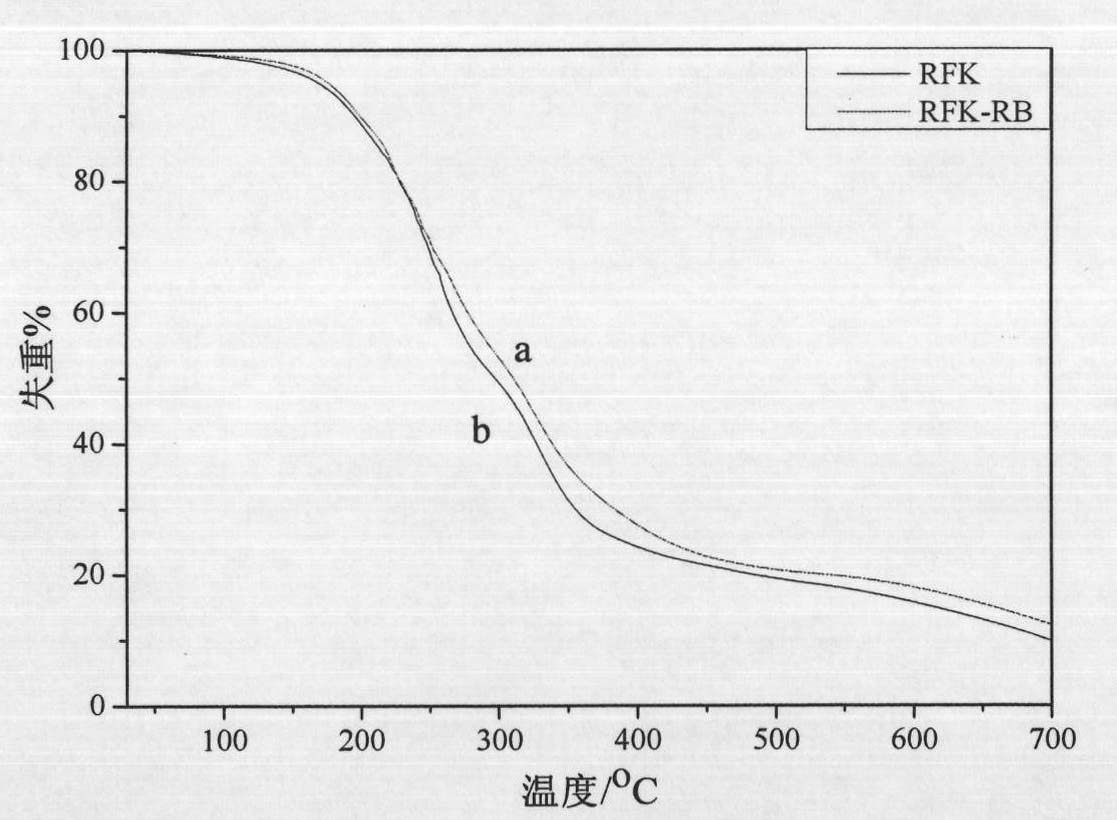

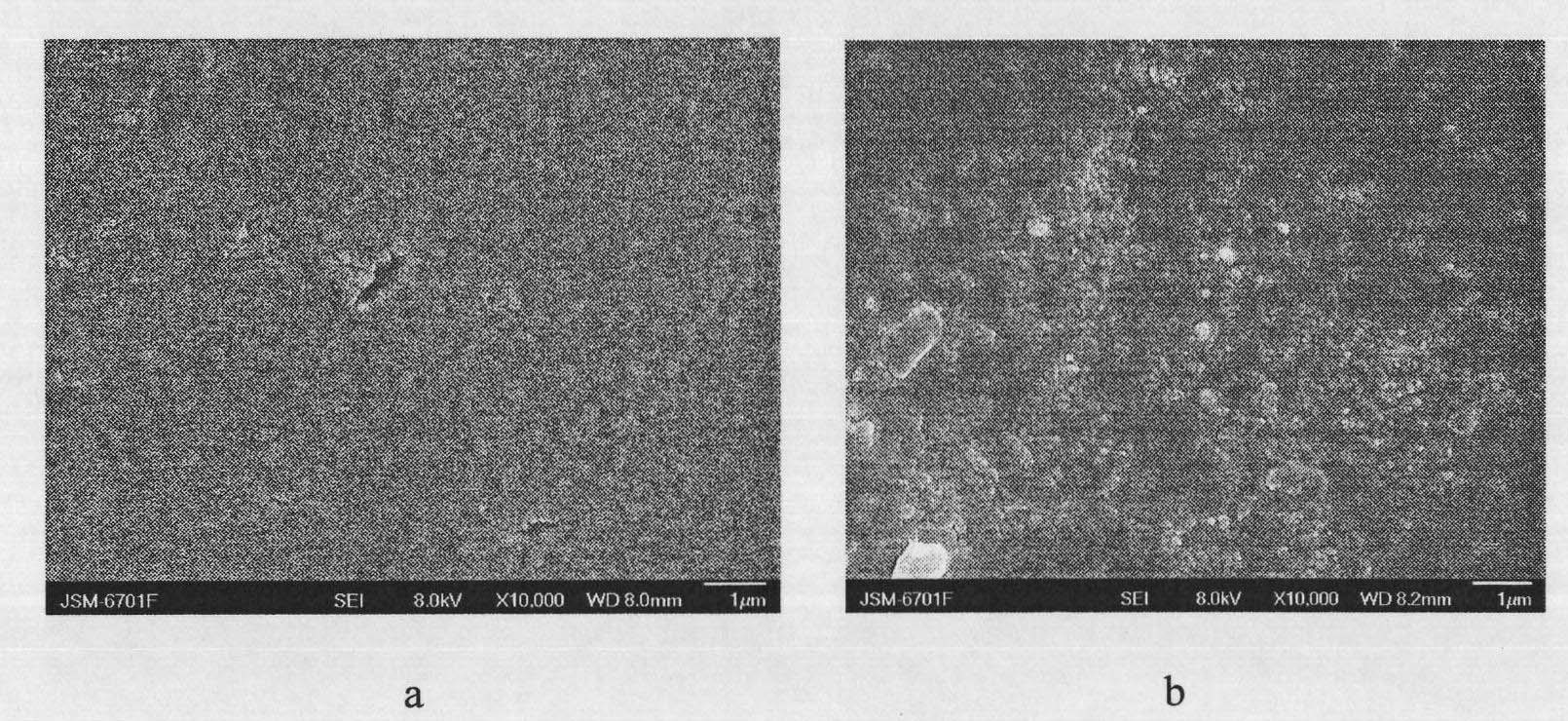

[0035]Embodiment 1: take by weighing 0.8g feather keratin powder, add 15mL secondary water wherein, add the mass concentration 1.5% sodium hydroxide solution of 8mL (the speed of dropping and the speed of stirring should be slower, contribute to like this The rapid dissolution of keratin, and the chemical properties of keratin will not change during the dissolution process), until the keratin powder is completely dissolved to obtain a keratin solution; Adjust to 7.3 (acid drop rate should also be appropriate, should not be too fast or too slow), then add 0.8g plasticizer, 0.002g rhodamine B to the keratin solution, stir at room temperature for 30min, make the keratin The protein solution, plasticizer, and drug are fully mixed to obtain a keratin drug film solution; finally, the keratin drug film solution is poured into a petri dish with a diameter of 8 cm, and a film is formed at 80°C.

[0036] The mechanical properties of the keratin drug-loaded film prepared in this example ...

Embodiment 2

[0037] Embodiment 2: take by weighing 0.8g feather keratin powder, add 15mL secondary water wherein, add the mass concentration 1.5% sodium hydroxide solution of 8mL (the speed of dropping and the speed of stirring should be slow, contribute to like this The rapid dissolution of keratin, and the chemical properties of keratin will not change during the dissolution process), until the keratin powder is completely dissolved to obtain a keratin solution; Adjust to 8.5 (acid drop rate should also be appropriate, should not be too fast or too slow), then add 0.8g plasticizer, 0.005g rhodamine B to the keratin solution, stir at room temperature for 30min, make the keratin The protein solution, plasticizer, and drug are fully mixed to obtain a keratin drug film solution; finally, the keratin drug film solution is poured into a petri dish with a diameter of 8 cm, and a film is formed at 80°C.

[0038] The mechanical properties of the keratin drug-loaded film prepared in this example a...

Embodiment 3

[0039] Embodiment 3: take by weighing 0.8g feather keratin powder, add 15mL secondary water wherein, add the mass concentration 1.5% sodium hydroxide solution of 8mL (the speed of dropping and the speed of stirring should be slow, contribute to like this The rapid dissolution of keratin, and the chemical properties of keratin will not change during the dissolution process), until the keratin powder is completely dissolved to obtain a keratin solution; Adjust to 9.3 (acid drop rate should also be appropriate, should not be too fast or too slow), then add 0.8g plasticizer, 0.012g rhodamine B to the keratin solution, stir at room temperature for 30min, make the keratin The protein solution, plasticizer, and drug are fully mixed to obtain a keratin drug film solution; finally, the keratin drug film solution is poured into a petri dish with a diameter of 8 cm, and a film is formed at 80°C.

[0040] The mechanical properties of the keratin drug-loaded film prepared in this example a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com