Steel protective cylinder guiding and installing method and pile foundation construction platform and floating crane ship

A technology of a construction platform and an installation method, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as unsuitable steel casings, and achieve the effects of reducing installation difficulty, reducing volume, and avoiding the overturning of steel casings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

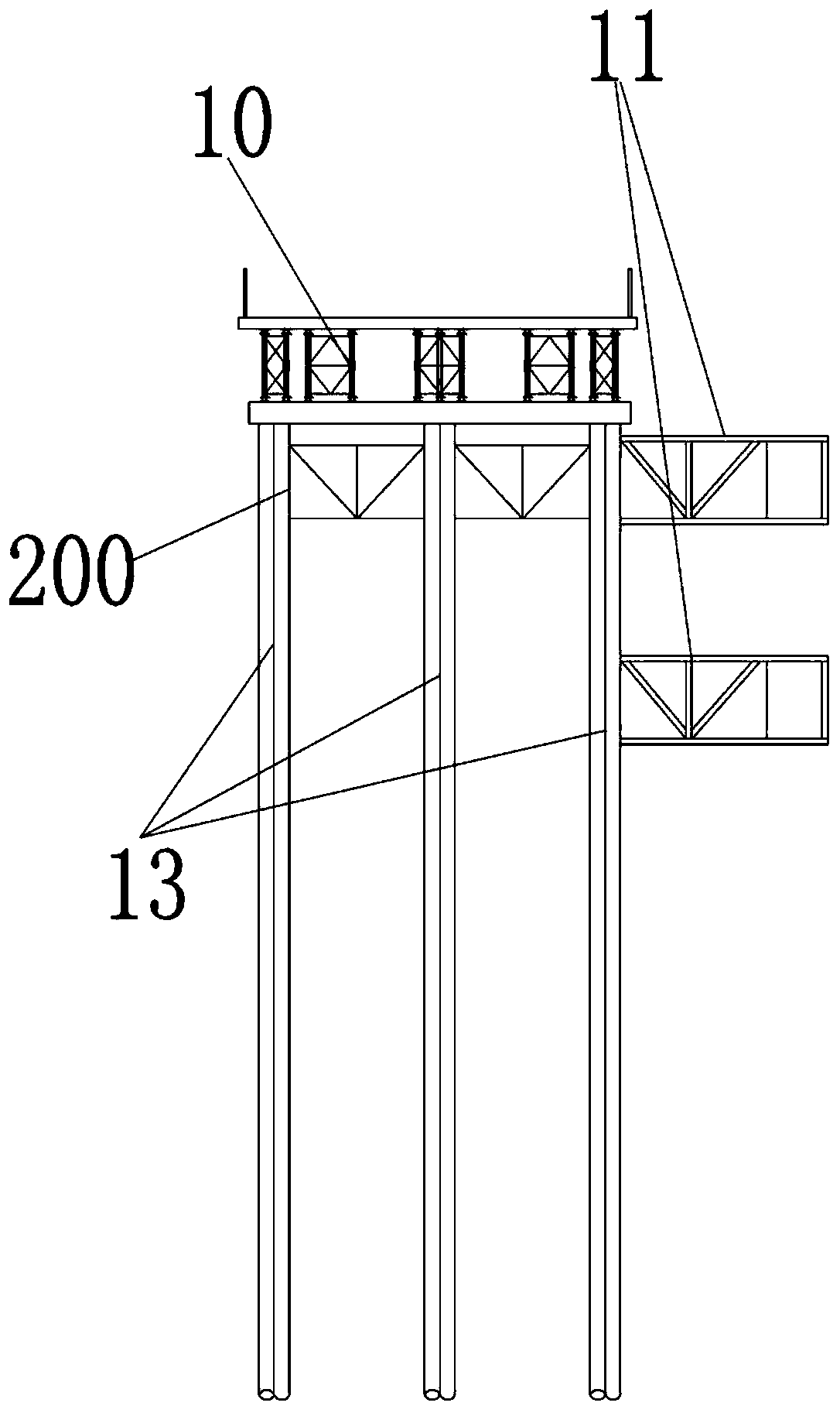

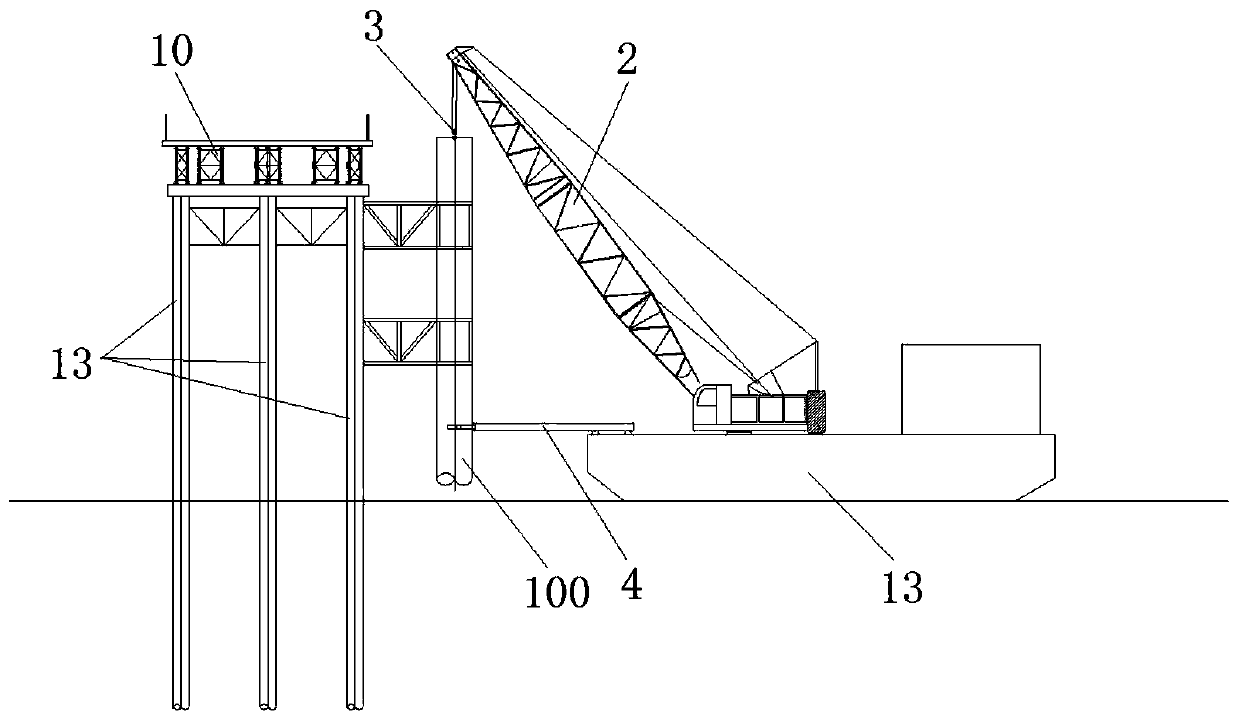

[0070] In order to realize the guide installation method of the above-mentioned steel casing, such as Figure 2 to Figure 4 Shown, the concrete embodiment of pile foundation construction platform of the present invention is as follows:

[0071] When building a pile foundation construction platform, it is necessary to guide and install the steel casing 100 on the already built construction platform 200. Correspondingly, for the convenience of guiding and installing the corresponding steel casing 100, a fixed positioning frame is fixed on the construction platform 200 11. Usually fixed by welding, because the fixed positioning frame 11 is used to position and place the steel casing 100, so the fixed positioning frame 11 is located on the construction platform 200 where the steel casing is preset to be installed.

[0072] The fixed positioning frame 11 includes a fixed fork head 110, and the corresponding end of the fixed fork head 110 facing away from the construction platform 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com