Shrimp peeling cutting device and shrimp peeling machine

A cutting device and shrimp peeling technology, applied in shrimp/lobster processing, slaughtering, crustacean/bivalve classification/classification, etc. The equipment has the advantages of light operation structure, simplified processing procedures and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

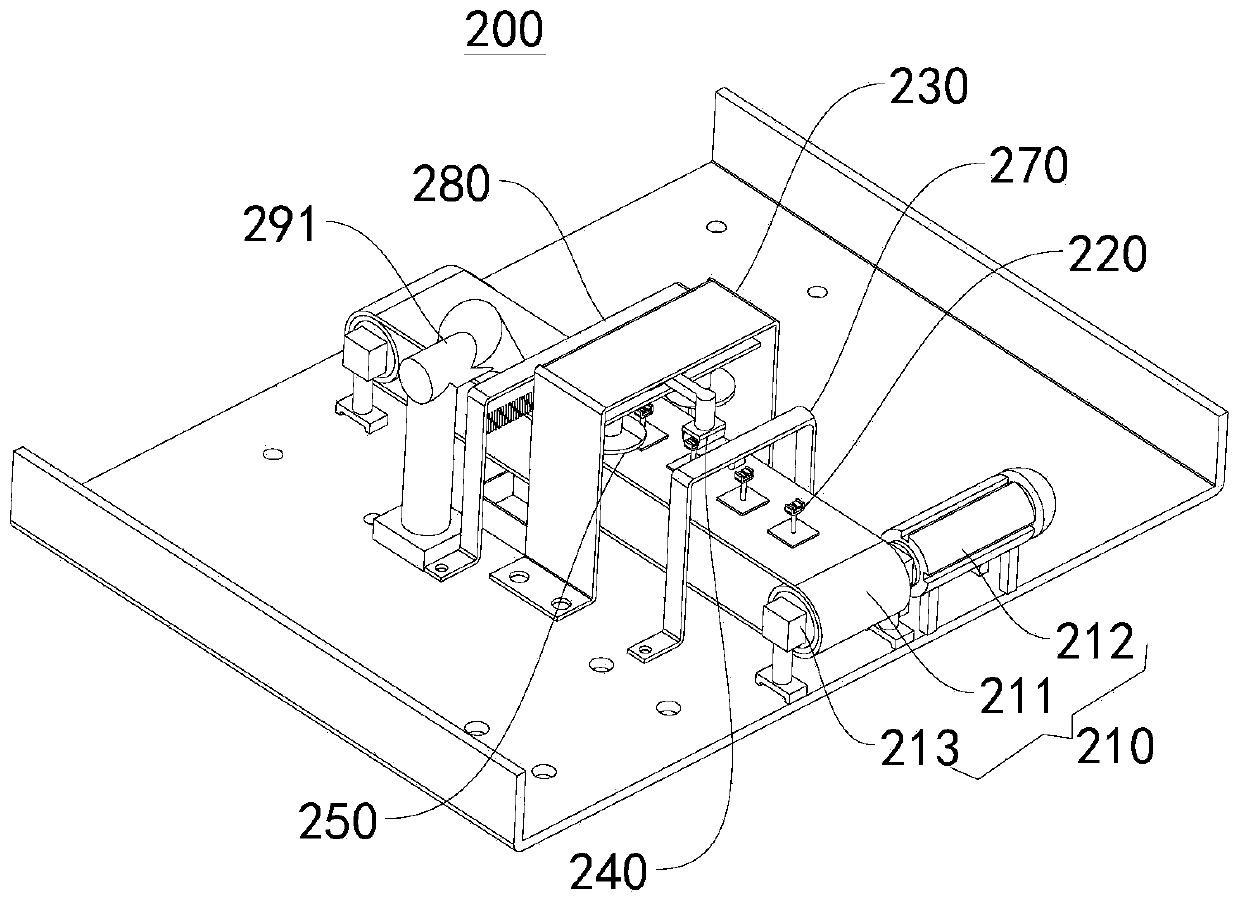

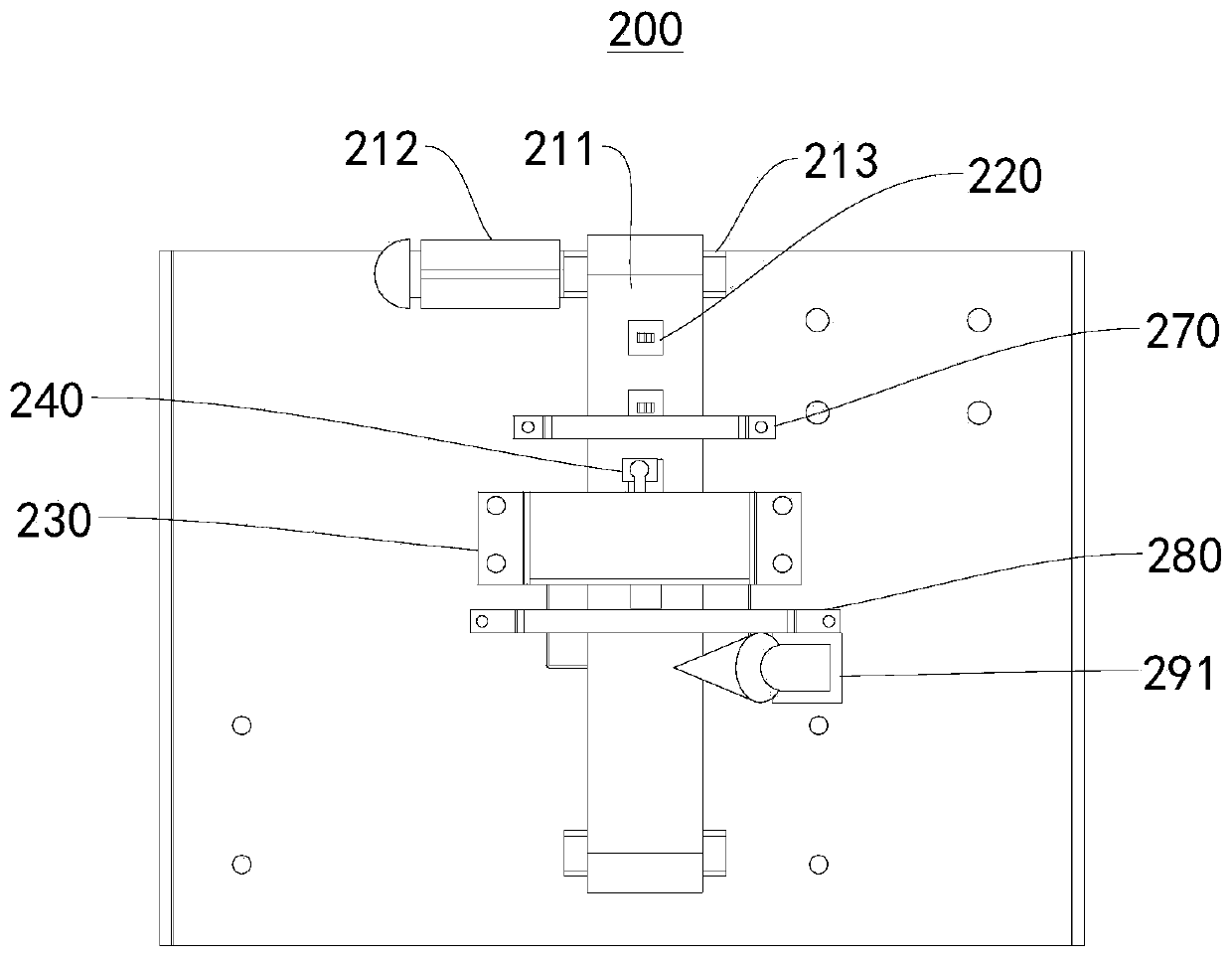

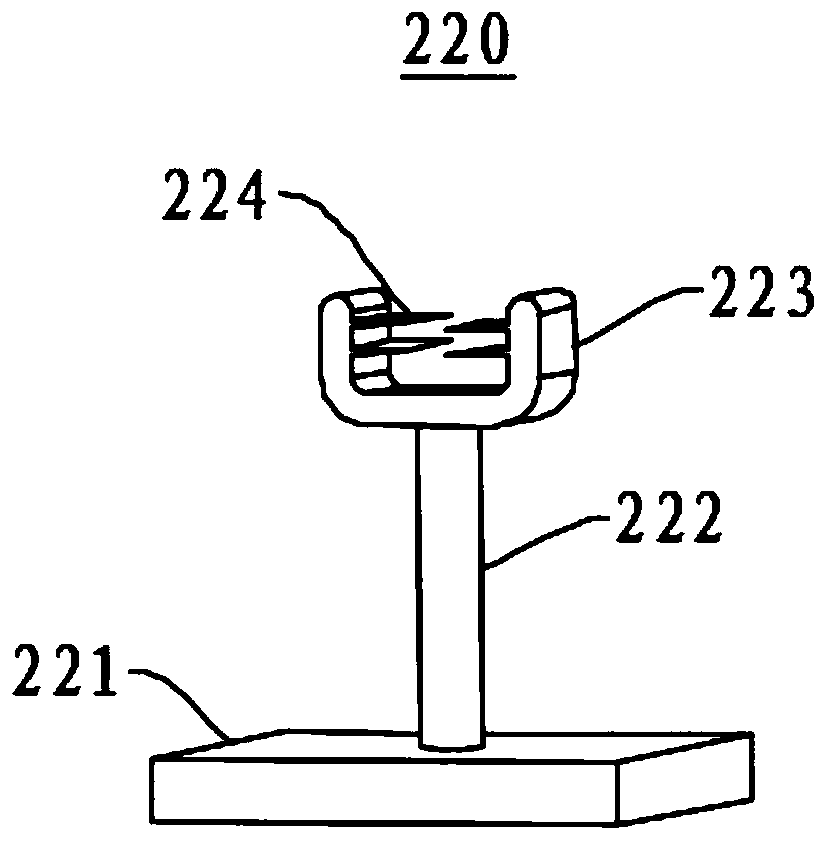

[0044] see figure 1 and figure 2 , the present embodiment provides a shrimp peeling and cutting device 200, which includes a transmission mechanism 210, a clamping mechanism 220, a knife holder 230, a head and tail cutter 240, a side cutter 250, a back cutter 260, a pressing mechanism 270, an intestine Wire brush 280 and cleaning mechanism 290. The clamping mechanism 220 is arranged on the transmission mechanism 210 and moves with the transmission mechanism 210 . The tool holder 230 is disposed above the conveyor belt 211 . The head and tail cutter 240 , the side cutter 250 and the back cutter 260 are respectively arranged at the front section, the middle section and the rear section of the knife holder 230 . Under the action of the conveying mechanism 210, the clamping mechanism 220 passes through the head and tail cutter 240, the side cutter 250 and the back cutter 260 in sequence, and undergoes head and tail cutting, side cutting and back cutting in sequence, thereby re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com