Treatment production line for testacean marine products

A production line and seafood technology, applied in the field of shell seafood processing production line, can solve the problems of limited production efficiency and production volume, low degree of automation, time-consuming and laborious, etc., achieve high degree of automation, improve production efficiency and processing efficiency and guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

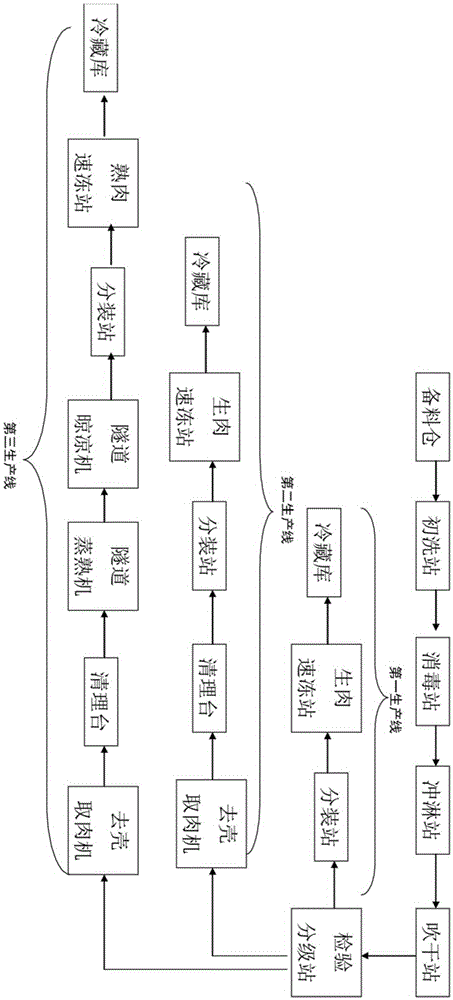

[0018] Such as figure 1 As shown, the shellfish processing production line according to the present invention mainly includes a pretreatment production line, a first production line, a second production line and a third production line, wherein:

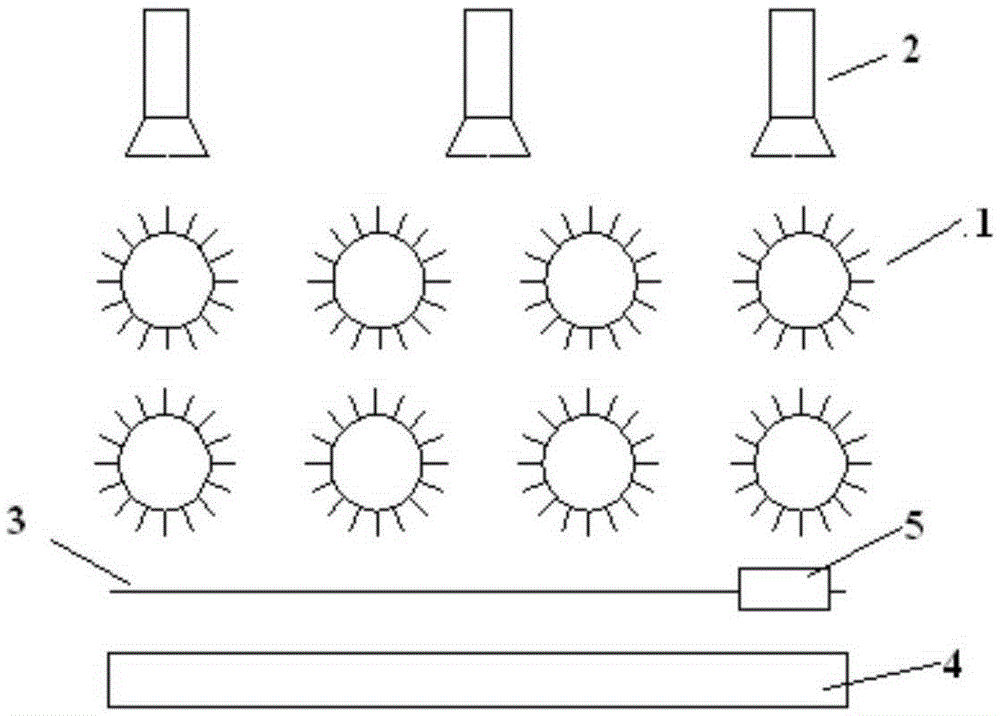

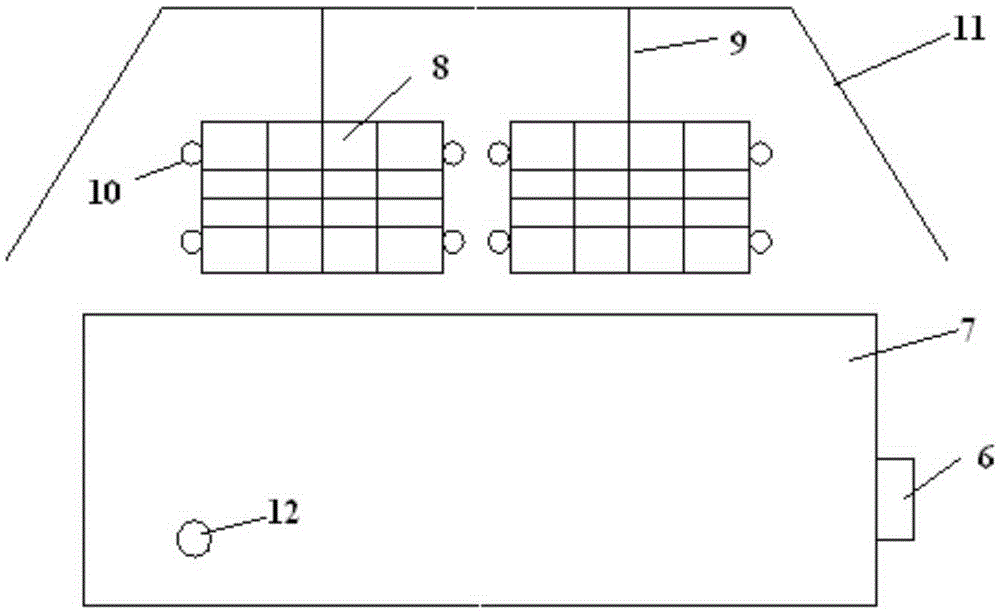

[0019] The pretreatment production line is used for preliminary cleaning and grading of seafood, including: stock preparation bin, primary washing station, disinfection station, shower station, drying station and inspection and grading station according to the processing sequence. The seafood that needs to be processed is first transported to the storage bin, stacked as needed, and waits for subsequent processing. Such as figure 1 As shown, the initial washing station is used to perform preliminary cleaning on the outside of the seafood, including the upper and lower brush roller groups 1, the high-pressure nozzle 2, the filter screen 3 arranged under the brush roller group, and the filter screen below the filter screen. sink4. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com