Production line for automatically stripping off shrimp shells

An assembly line and shrimp peeling technology, which is applied in the processing of crustaceans, shrimp/lobster processing, slaughtering, etc., can solve the problems of being easily scratched by blades, more broken shrimp skins, and slow peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The embodiments in the following description are only examples, and those skilled in the art can think of other obvious modifications.

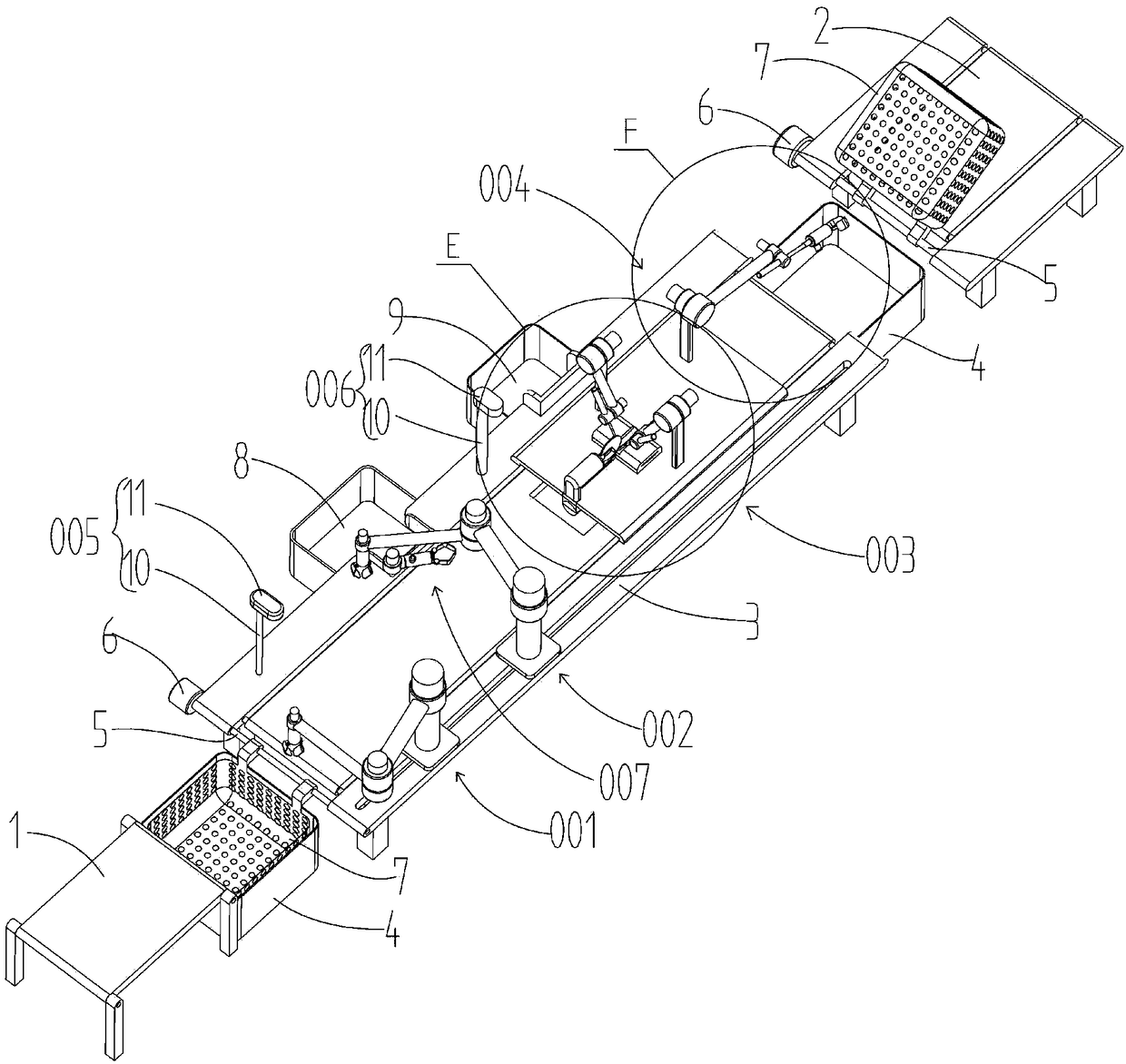

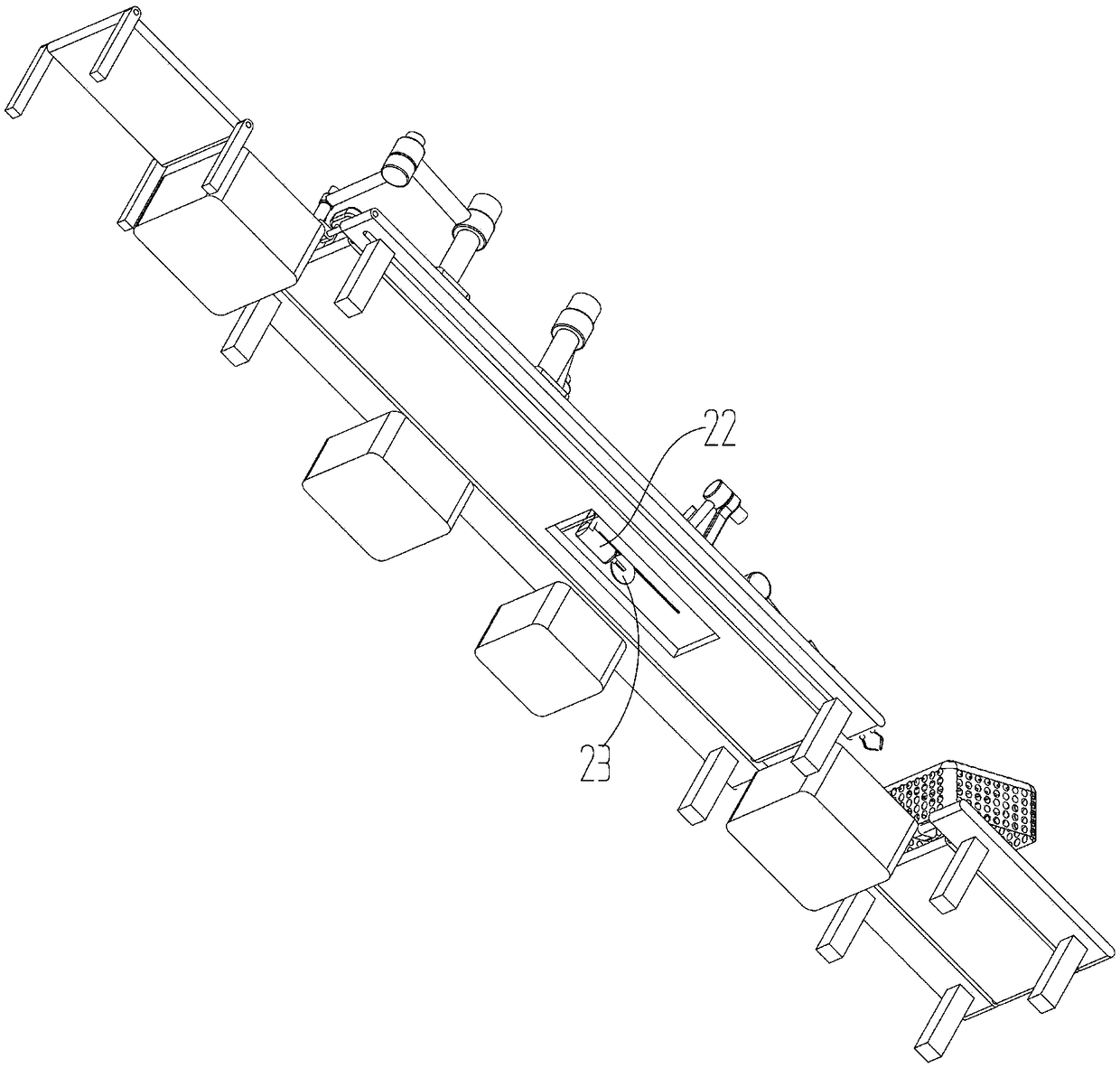

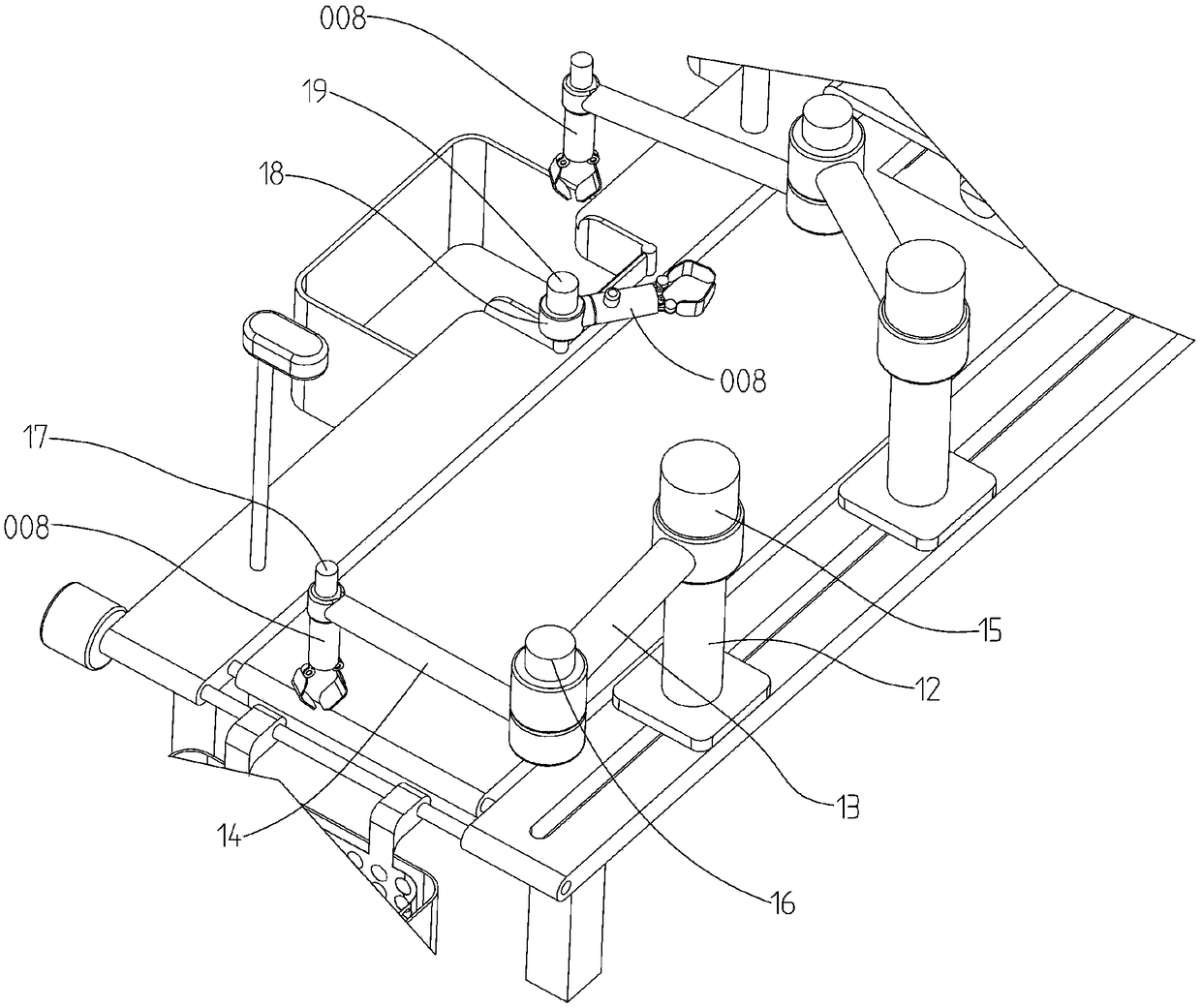

[0025] Such as Figure 1-8 As shown, an automatic shell peeling assembly line includes a first conveyor belt 1, a second conveyor belt 2, and a shrimp peeling console 3, and the first conveyor belt 1 and the second conveyor belt 2 are respectively located at both ends of the shrimp peeling console 3; An ultrasonic cleaning pool 4 is placed between one end of the shrimp peeling operation platform 3 and the first conveyor belt 1, and between the other end and the second conveyor belt 2; And on the second conveyer belt 2, a rotating shaft 5 and a driving motor 6 for driving the rotating shaft 5 are installed on the end close to the shrimp peeling operation table 3, and the rotating shaft 5 is fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com