Electric step plate

A stepping board, electric technology, applied in the layout, transportation and packaging of pedals or ladders, vehicle parts, etc., can solve the problems of easy jamming, inconvenient manual return operation, sinking of the stepping board, etc., to avoid the bearing capacity. Small, stable and reliable transmission mechanism, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

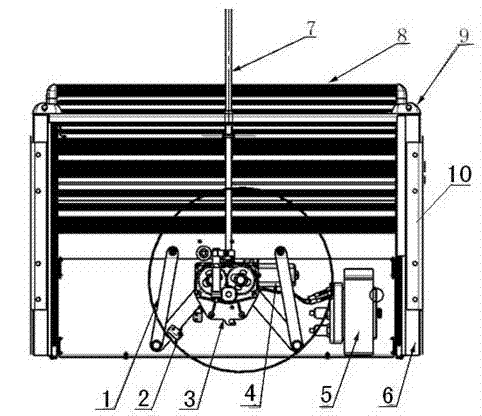

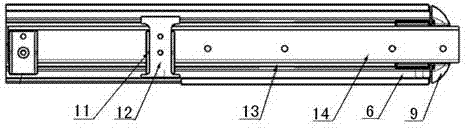

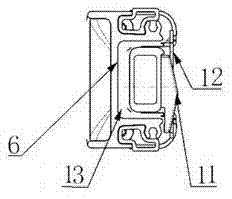

[0018] Depend on figure 1 It is known that the electric step board includes a frame mechanism, a link mechanism, a guide mechanism, a drive mechanism and a pedal assembly 8. The frame mechanism is composed of a front limit plate 9, a guide outer arm 6 and a side bracket 10, and the link mechanism is composed of The connecting rod I1 and the connecting rod II2 are composed, the driving mechanism is composed of the motor 4, the gear assembly 3 and the controller 5; The pedal assembly 8 is inserted into the frame mechanism and can slide along the frame side bracket 10, and the frame mechanism is connected with the vehicle body. The drive motor 4 is connected to the main shaft of the gear assembly 3, one end of the connecting rod I2 is connected to the shaft on one side of the gear assembly 3, the middle is connected to the connecting rod II1, one end of the connecting rod II1 is connected to the pedal assembly 8, and the two sides of the driving motor 4 Symmetrically arrange the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com