Electrode of supercapacitor, preparation method of electrode and preparation method of slurry of electrode

A supercapacitor, electrode technology, applied in capacitors, electrolytic capacitors, protection/regulating hybrid/electric double-layer capacitors, etc., can solve the problems of clogging, weak bonding, and insufficient flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

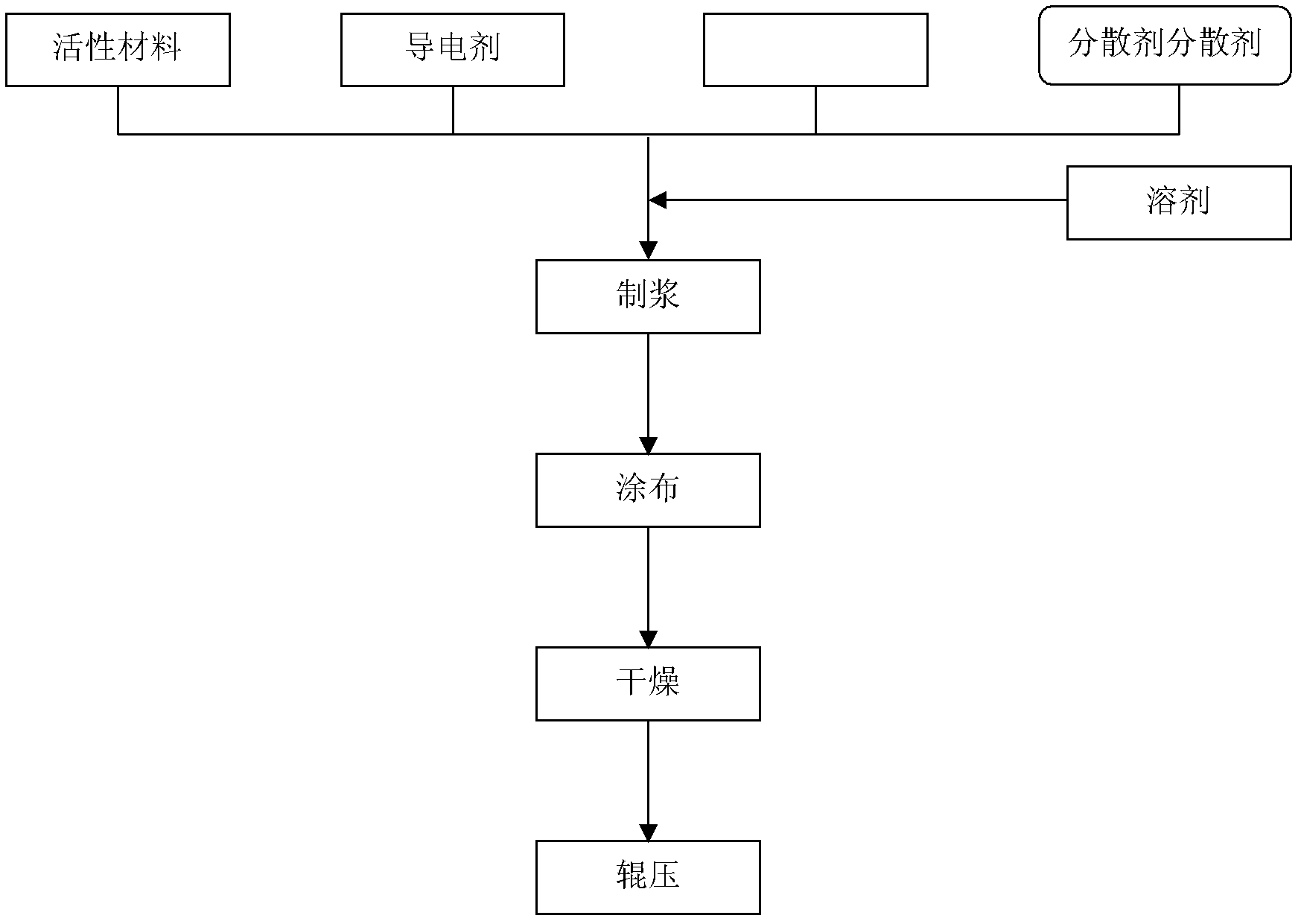

[0056] The schematic diagram of the preparation process of the electrode for the supercapacitor of the present invention is as follows figure 2 , which mainly includes the following steps:

[0057] A. Pulping, that is, mixing active materials, conductive agents, dispersants, binders and solvents to prepare slurry;

[0058] B. Slurry coating, that is, coating the slurry obtained in step A on the current collector to become a pretreatment electrode;

[0059] C. drying, that is, baking the pretreated electrode to remove volatile components therein;

[0060] D. Rolling, that is, rolling and compacting the pretreated pole piece obtained in step C to become an electrode.

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

Embodiment 1

[0063] First, mix 100 parts by mass of activated carbon, 9.3 parts by mass of conductive carbon black, 3.1 parts by mass of dispersant, 3.5 parts by mass of the first binder and 220 parts by mass of water to prepare slurry , the slurry preparation process is as follows:

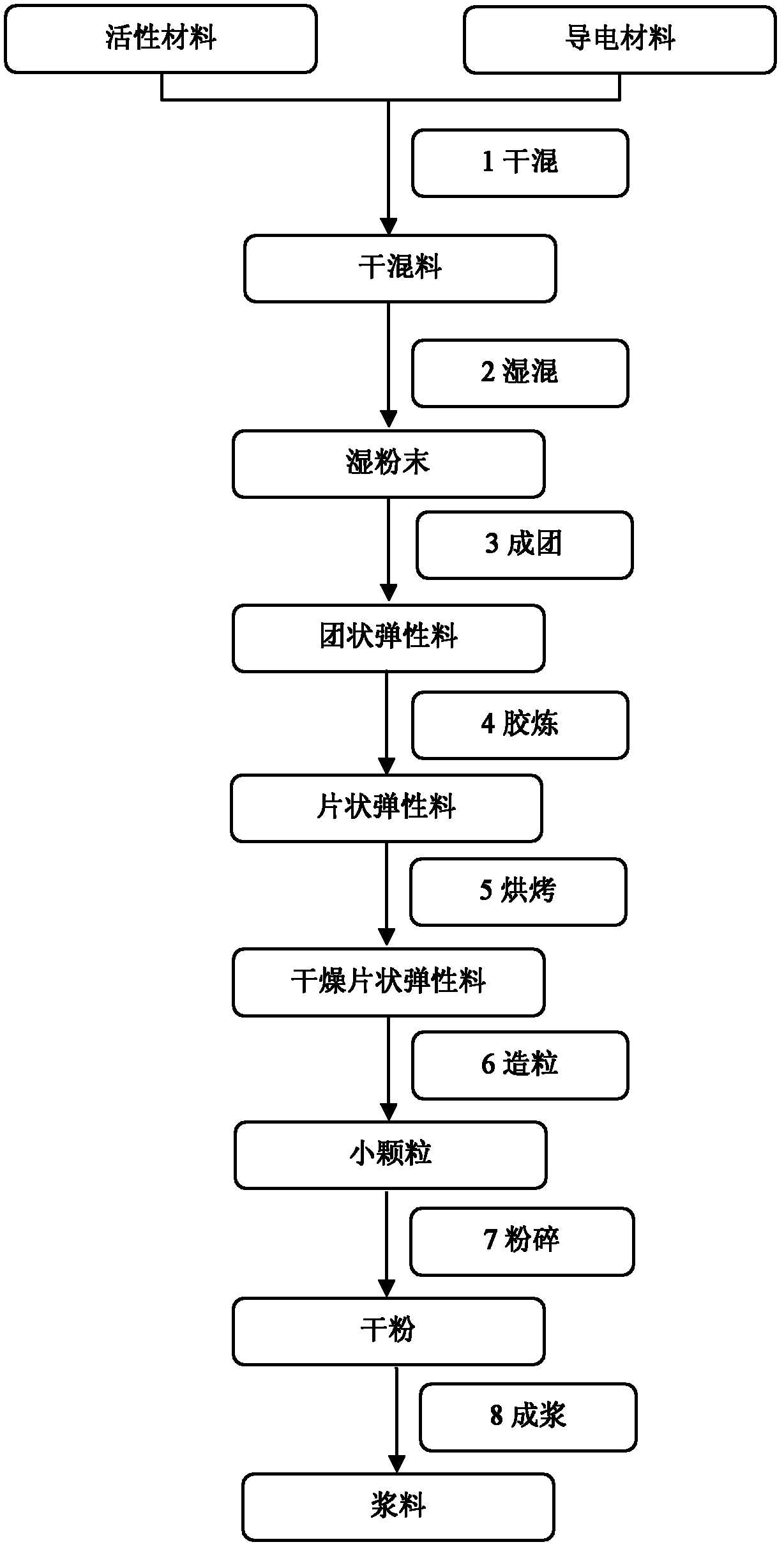

[0064] Place activated carbon and conductive carbon black in a sealed double-cone high-efficiency mixer for high-speed mixing for 8 hours to obtain a fully mixed and uniform dry mix; then add water and dispersant (the temperature of the dispersant is controlled at 20-55°C), Control the solid content at 70% to 80%, use a power mixer to stir for 1 hour, and mix the materials into wet powder. Continue to add dispersant, control the solid content at 50% to 60%, increase the stirring speed to form a flexible lump material (flexibility refers to the property that the object is not easy to break after being deformed by force); use noodles machine to knead the agglomerate material into a sheet-like elastic material;...

Embodiment 2

[0069] First, mix 100 parts by mass of activated carbon, 9.3 parts by mass of conductive graphite, 3.8 parts by mass of dispersant, 3.4 parts by mass of the first binder, and 272 parts by mass of water to prepare slurry , the slurry preparation process is as follows:

[0070] Place activated carbon and conductive carbon black in a sealed double-cone high-efficiency mixer for high-speed mixing for 8 hours to obtain a fully mixed and uniform dry mix; then add water and dispersant (the temperature of the dispersant is controlled at 20-55°C), Control the solid content at 70% to 80%, use a power mixer to stir for 1 hour, and mix the materials into wet powder. Continue to add dispersant, control the solid content at 50% to 60%, increase the stirring speed to form a flexible mass material; use a noodle machine to glue the mass material into a sheet-like elastic material; The material is baked in a blast oven at 120°C for 8 hours to obtain a dry sheet-shaped elastic material; use a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com