Preparation of layered metal organic framework material nano-array water oxidation electrocatalyst using LDH as template

A nano-array and layered structure technology, applied in the three-dimensional field with highly regular arrangement, can solve the problems of increased contact resistance of active sites, reduced catalytic activity, high energy consumption and structural loss of MOFs derived materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

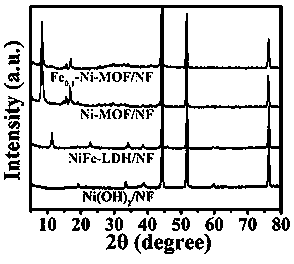

[0023] 1) Preparation A: Ni(NO 3 ) 2 ·6H 2 O (2.025 mmol), Fe(NO 3 ) 3 9H 2 O (0.225 mmol), CO (NH 2 ) 2 (10mmol) and NH 4 F (4 mmol), dissolved in 40 mL deionized water, stirred evenly, one piece size is 2×3 cm 2 Nickel foam (NF) was pretreated with 5% dilute hydrochloric acid, deionized water and absolute ethanol for 10 min of ultrasonication;

[0024] 2) Hydrothermal reaction: transfer the solution and treated NF in step 1) to a 50 mL polytetrafluoroethylene autoclave, seal the autoclave, place it in a vacuum oven, and react at 120 °C for 6 h;

[0025] 3) Washing and drying: After the reaction in step 2) is completed, put the polytetrafluoroethylene autoclave in the air to cool to room temperature, take out the NF uniformly covered by the yellow-green substance, and ultrasonically wash it with deionized water and absolute ethanol successively. After that, it was vacuum dried at 60 ℃ for 6 h to prepare the NiFe-LDH / NF precursor;

[0026] 4) Prepare material B: C ...

example 2

[0031] 1) Preparation A: Ni(NO 3 ) 2 ·6H 2 O (4.05 mmol), Fe(NO 3 ) 3 9H 2 O (0.45 mmol), CO (NH 2 ) 2 (20mmol) and NH 4 F (8 mmol), dissolved in 80 mL deionized water, stirred evenly, one piece size is 4×6 cm 2 Nickel foam (NF) was pretreated with 5% dilute hydrochloric acid, deionized water and absolute ethanol for 10 min of ultrasonication;

[0032] 2) Hydrothermal reaction: transfer the solution and treated NF in step 1) to a 100 mL polytetrafluoroethylene autoclave, seal the autoclave, place it in a vacuum drying oven, and react at 120 °C for 6 h;

[0033] 3) Washing and drying: After the reaction in step 2) is completed, put the polytetrafluoroethylene autoclave in the air to cool to room temperature, take out the NF uniformly covered by the yellow-green substance, and ultrasonically wash it with deionized water and absolute ethanol successively. After that, it was vacuum dried at 60 ℃ for 6 h to prepare the NiFe-LDH / NF precursor;

[0034] 4) Prepare material ...

example 3

[0039] 1) Preparation A: Ni(NO 3 ) 2 ·6H 2 O (4.05 mmol), Fe(NO 3 ) 3 9H 2 O (0.45 mmol), CO (NH 2 ) 2 (20mmol) and NH 4 F (8 mmol), dissolved in 80 mL deionized water, stirred evenly, one piece size is 4×6 cm 2 Nickel foam (NF) was pretreated with 5% dilute hydrochloric acid, deionized water and absolute ethanol for 10 min of ultrasonication;

[0040] 2) Hydrothermal reaction: transfer the solution and treated NF in step 1) to a 100 mL polytetrafluoroethylene autoclave, seal the autoclave, place it in a vacuum drying oven, and react at 120 °C for 6 h;

[0041] 3) Washing and drying: After the reaction in step 2) is completed, put the polytetrafluoroethylene autoclave in the air to cool to room temperature, take out the NF uniformly covered by the yellow-green substance, and ultrasonically wash it with deionized water and absolute ethanol successively. After that, it was vacuum dried at 60 ℃ for 6 h to prepare the NiFe-LDH / NF precursor;

[0042] 4) Prepare material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com