Flexible lithium ion battery black phosphorus nanosheet-graphene composite film anode, and preparation thereof

A graphene composite and lithium-ion battery technology, applied in the field of electrochemical batteries, can solve the problems of poor conductivity and stability, achieve good flexibility and strength, high efficiency, and improve the effect of rate performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the specific implementation process, the present invention proposes a black phosphorus nanosheet-graphene composite film negative electrode for lithium ion batteries and a preparation method thereof. The black phosphorus block is combined with a mineral-assisted gas phase transport method, and then prepared by Tip ultrasound. Black phosphorous nano flake powder, black phosphorous nano flakes and graphene are dispersed in an organic solvent in a certain proportion, and then ultrasonicated and vacuum filtered on the organic membrane. After vacuum drying, the film is directly peeled off from the organic membrane to obtain black phosphorus Nanosheet-graphene composite film negative electrode. Specific steps are as follows:

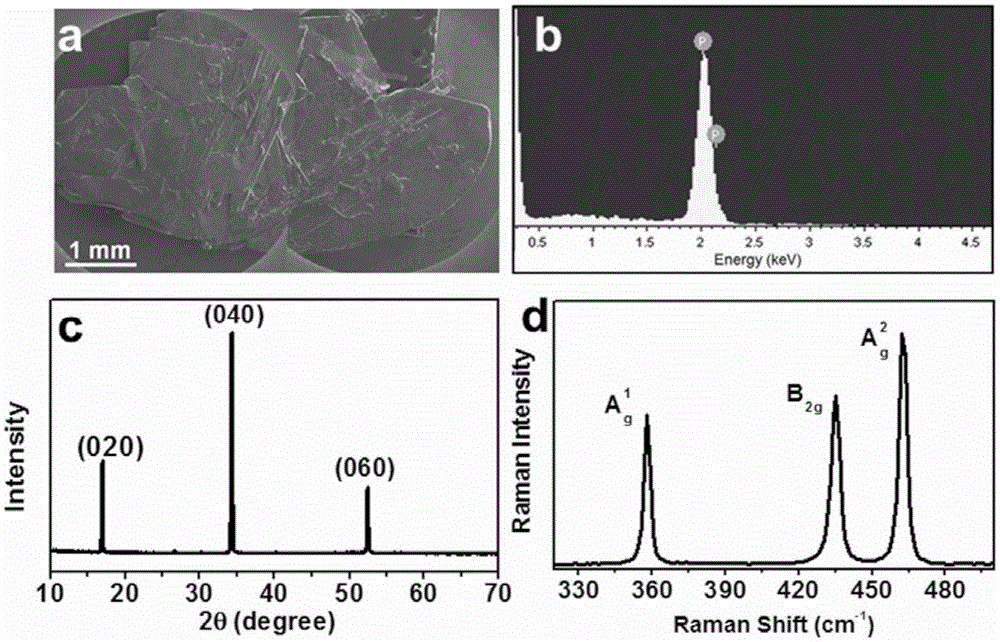

[0042] (1) Using mineral-assisted gas-phase transport method to synthesize black phosphorus bulk: red phosphorus, gold tin alloy (AuSn, alloy grades such as: AuSn20, AuSn27 or AuSn90, etc.) and tin tetraiodide according to 900:360:18 The weight ratio i...

Embodiment 1

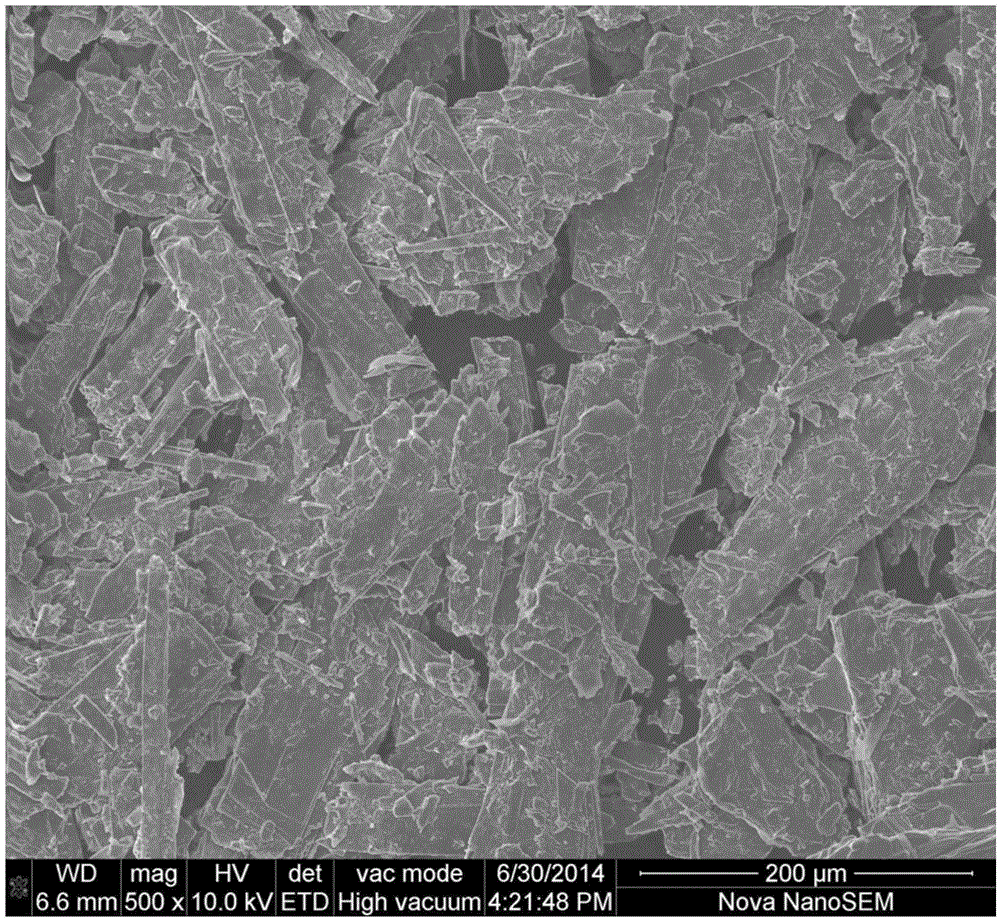

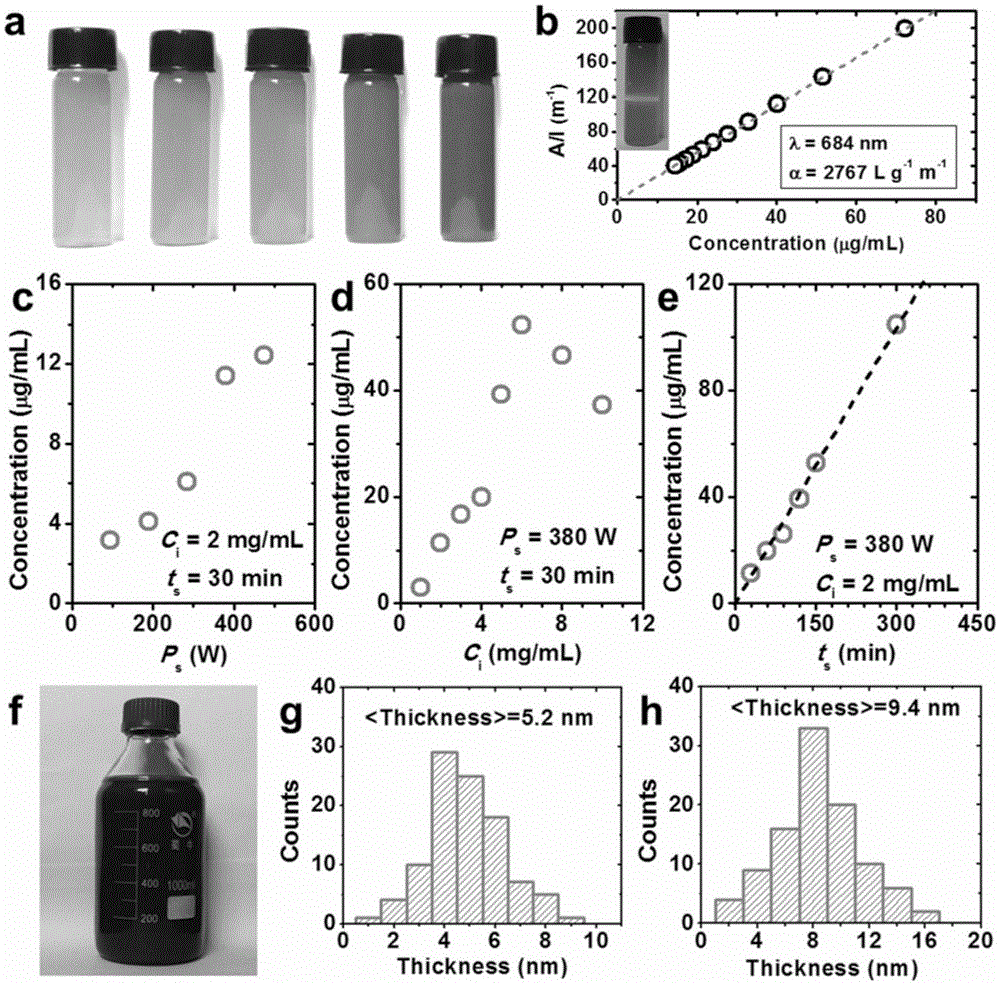

[0052] 1000mg of black phosphorus block is put into a mortar and ground into powder (see figure 2 ), put the black phosphorus powder into a glass bottle containing 200 mL of deionized water (the black phosphorus content is 5 mg / mL). Use Tip ultrasonic to peel off the black phosphorous block to prepare black phosphorous nanosheets (ultrasonic power is 380W, ultrasonic time is 3h), after the end of the ultrasonic, let stand for 12h, centrifuge at 5000 rpm for 30min, take out the supernatant, and obtain black phosphorous nano Dispersion of tablets in water. The above dispersion was vacuum filtered and washed with ethanol, and then dried under vacuum at 60°C for 12 hours to obtain black phosphorous nanosheet powder (average thickness of about 5.2nm, see image 3 g; the lateral dimension is 50~250nm, see Figure 4 a-c). 12mg (80wt%) of black phosphorus nanoplate powder and 3mg (20wt%) of graphene were added to N-methylpyrrolidone (40mL) organic solvent, and ordinary ultrasound (190...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com