Anti-oxygenation maillard flavor peptides and method for preparing same

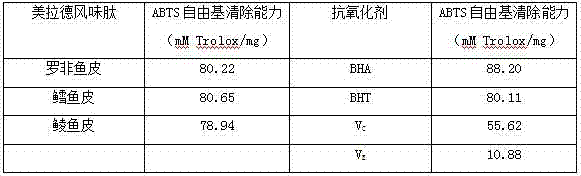

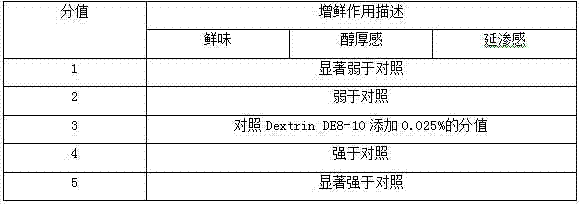

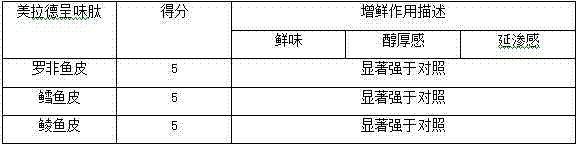

A technology of anti-oxidation and taste peptide, applied in the field of food science, can solve problems such as fishy smell and deep color, and achieve the effect of enhancing umami, simple process and strong anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Raw material pretreatment: Accurately weigh 0.5 kg of tilapia skin, wash and mince, add 5 L of 0.05 mol / L NaOH solution to soak for 30 min, and wash with water until neutral. Then add 5L of 0.2% sulfuric acid solution to soak for 30min, wash with water until neutral, finally add 5L of water, extract at 50°C overnight, centrifuge at 5,000×g for 20min, and the supernatant is collagen extract;

[0021] (2) Controllable enzymatic hydrolysis of collagen: take collagen extract, concentrate, adjust its concentration to 10%, adjust its pH to 8.0 with 1mol / L NaOH solution, heat to 50°C, add collagen 0.5% by weight Protease and 1% alkaline protease, hydrolyze at constant temperature, monitor the degree of hydrolysis, when the degree of hydrolysis is about 20%, heat the hydrolyzate to 90°C, keep it for 10 minutes to kill the enzyme, after cooling, centrifuge at 5,000×g for 15 minutes, collect the supernatant, The supernatant is an enzymatic hydrolysis solution;

[0022] (3) U...

Embodiment 2

[0025] (1) Raw material pretreatment: Accurately weigh 0.5kg of cod skin, wash and mince, add 2.5L of 0.1mol / L NaOH solution to soak for 10min, and wash with water until neutral. Then add 2.5L of 0.5% sulfuric acid solution to soak for 10min, wash with water until neutral, finally add 2.5L of water, extract overnight at 70°C, centrifuge at 5,000×g for 20min, collect the supernatant, which is the collagen extract;

[0026] (2) Controllable enzymatic hydrolysis of collagen: Concentrate the collagen extract, adjust its concentration to 1%, adjust its pH to 8.0 with 1mol / L NaOH solution, heat to 45°C, add 2% of collagen weight alkali Protease, constant temperature hydrolysis, monitor the degree of hydrolysis, when the degree of hydrolysis is about 23%, heat the hydrolyzate to 90°C, keep it for 10 minutes to inactivate the enzyme, after cooling, centrifuge at 5,000×g for 15 minutes, collect the supernatant, which is the enzyme Solution;

[0027] (3) Ultrafiltration enrichment of 1...

Embodiment 3

[0030] (1) Raw material pretreatment: Accurately weigh 0.5kg of dace skin, wash and mince, add 7.5L of 0.01mol / L NaOH solution to soak for 60min, and wash with water until neutral. Then add 7.5L of 0.05% sulfuric acid solution to soak for 60min, wash with water until neutral, finally add 7.5L of water, extract overnight at 30°C, centrifuge at 5,000×g for 20min, collect the supernatant, which is the collagen extract;

[0031] (2) Controllable enzymatic hydrolysis of collagen: Concentrate the collagen extract, adjust its concentration to 15%, adjust its pH to 7.0 with 1mol / L NaOH solution, heat to 55°C, add trypsin with 1% collagen weight , constant temperature hydrolysis, monitor the degree of hydrolysis, when the degree of hydrolysis is about 17%, raise the temperature of the hydrolyzate to 90°C, keep it for 10min to inactivate the enzyme, after cooling, centrifuge at 5,000×g for 15min, collect the supernatant, which is the enzymatic hydrolyzate ;

[0032] (3) Ultrafiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com