Method for improving flavor of potamocorbula enzymatic hydrolysate by photocatalysis combined with fermentation

An enzymatic hydrolysate and photocatalytic technology of blue clams, applied in food science, food preservation, application and other directions, can solve the problems of insufficient umami, restrict development and application, poor overall flavor, etc., improve taste and smell, prolong shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

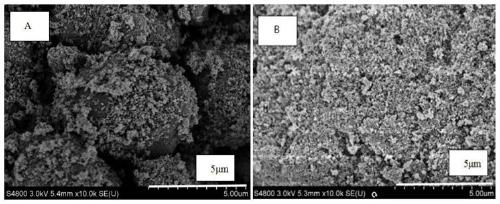

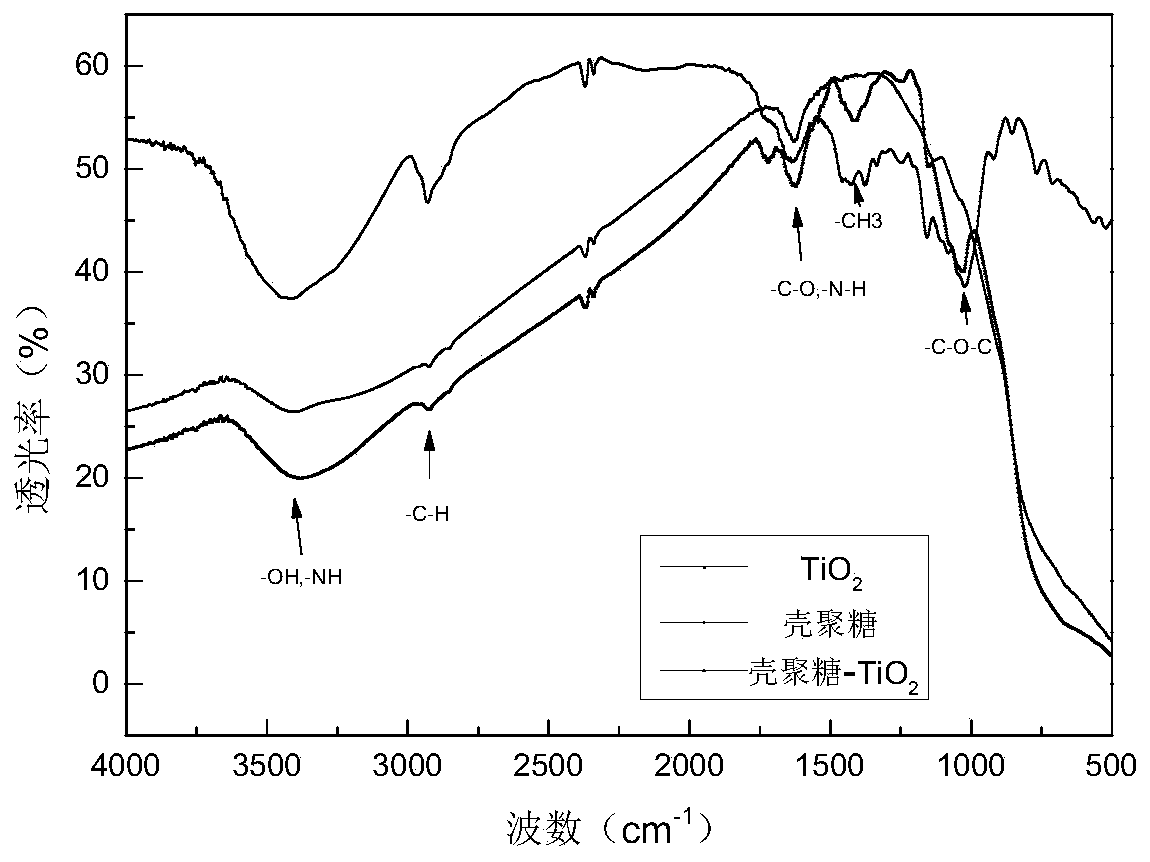

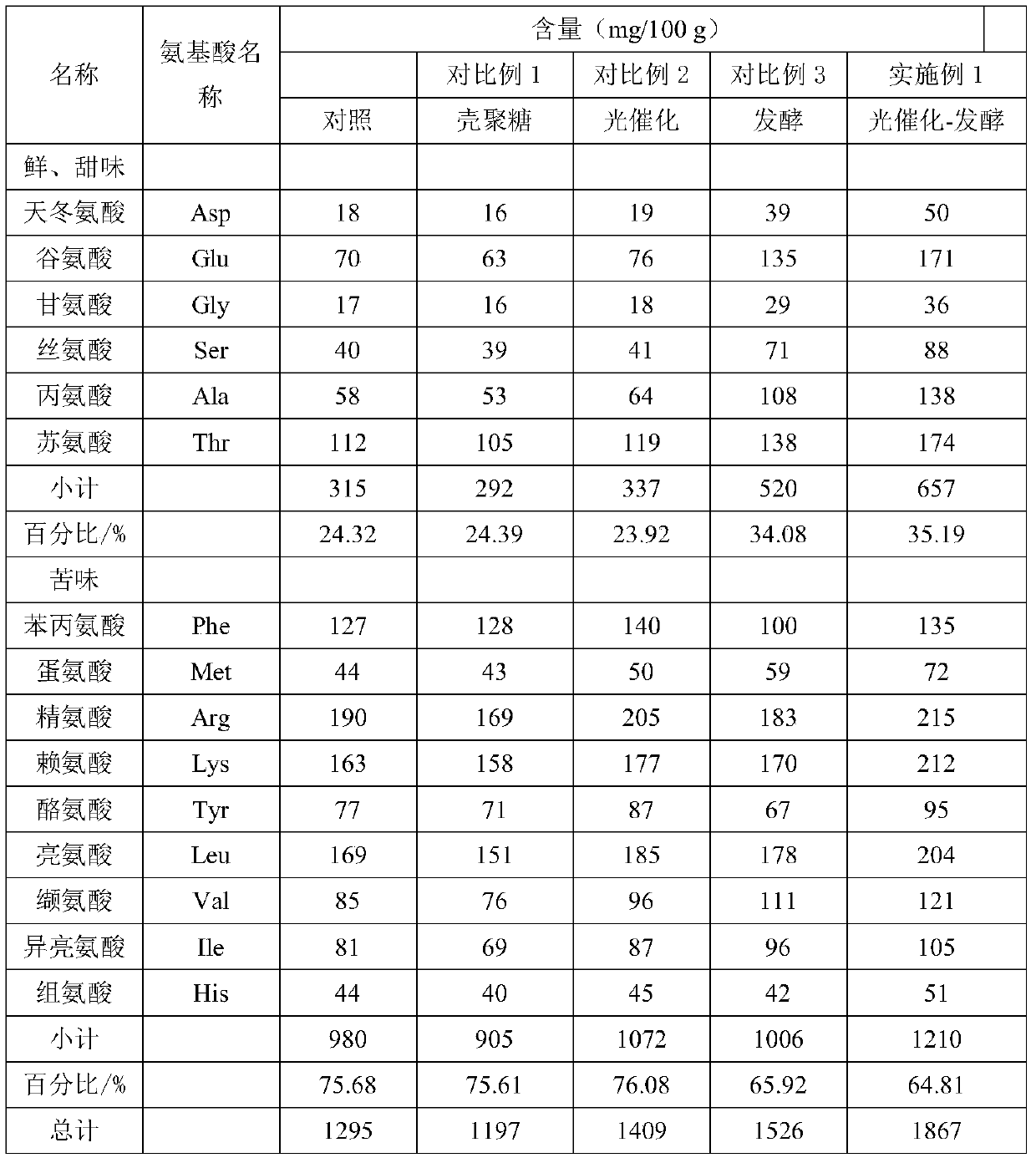

[0023] The invention discloses a method for improving the flavor of blue clam enzymatic liquid by combining photocatalysis and fermentation, that is, improving the flavor of blue clam enzymatic liquid by using the method combining yeast fermentation and photocatalytic technology.

[0024] A method for improving the flavor of clam enzymatic hydrolyzate in combination with photocatalysis and fermentation, comprising the following steps:

[0025] 1) Quick-freeze fresh and live blue clams after spitting sand, remove the shells and take the meat in the frozen state, add deionized water according to the mass ratio of material to liquid at 1:3, add 0.15% compound protease for enzymatic hydrolysis for 8 hours, and then inactivate the enzyme to prepare blue clams enzymatic solution;

[0026] 2) Add 1-3% activated yeast and 4-8% glucose to the blue clam enzymatic solution obtained in step 1), and ferment at 25°C for 120min;

[0027] 3) adding chitosan to mass concentration is 0.5% glac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com