Self-healing polymer material and preparation method thereof

A polymer material and self-healing technology, applied in the field of polymers, can solve the problems of low loading of repairing agent, inability to achieve multiple reversible self-repairing, restricting marketization, etc., to achieve the effect of easier adjustment of content and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Specifically, one aspect of the present invention provides a self-healing polymer material, comprising at least one polyurethane polymer formed by random copolymerization of an oligomer diol, a chain extender, and a first diisocyanate, said The chain extenders comprise at least one multiple hydrogen bond chain extender prepared by:

[0031] Step i) reacting 2-amino-4[1H]-pyrimidinone compound with a second diisocyanate to prepare an intermediate whose terminal group is an isocyanate group;

[0032] Step ii) reacting the intermediate obtained in step i) with a diol with a single amino group to prepare a multiple hydrogen bond chain extender;

[0033] Wherein, the 2-amino-4[1H]-pyrimidinone compound is that the 5-position and / or 6-position is replaced by H, C 1-4 Alkyl or C 1-4 Hydroxyalkyl-substituted 2-amino-4[1H]-pyrimidinones.

[0034] Preferably, when the 2-amino-4[1H]-pyrimidinone compound is 5 and / or 6 by H, C 1-4 In the case of alkyl-substituted 2-amino-4[1H]-...

Embodiment 1

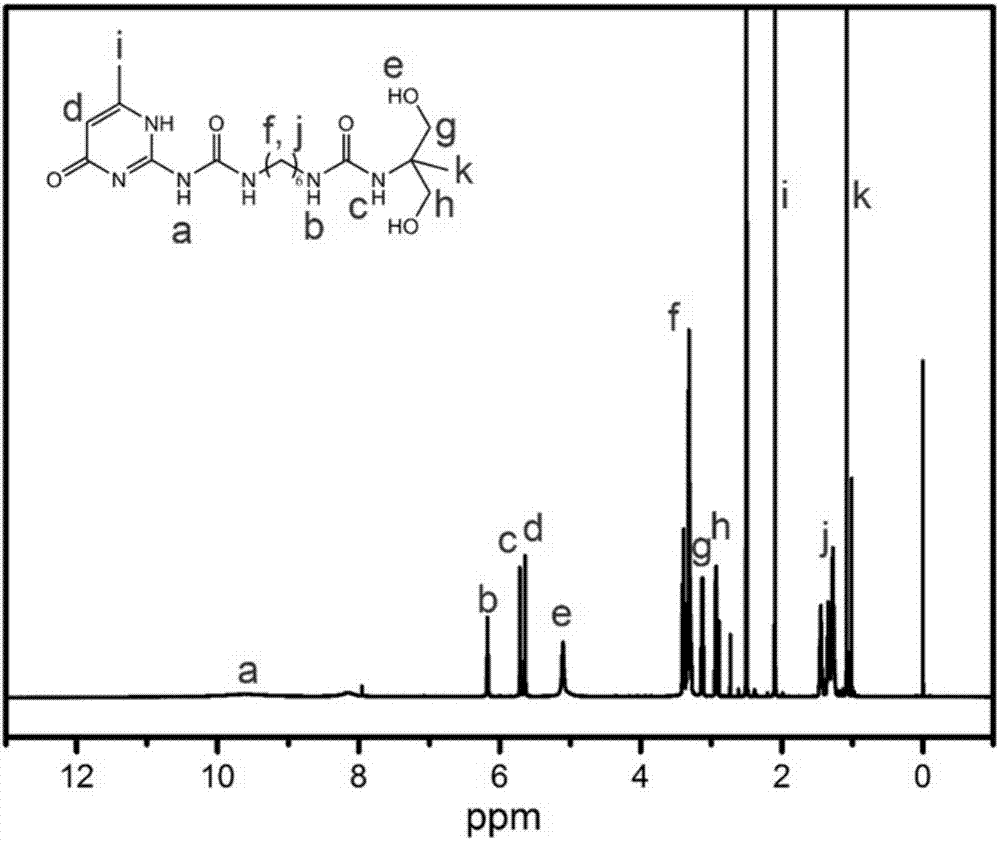

[0059] Synthesis of UPy-NCO end-capping agent and corresponding chain extender: by mole fraction, 1 part of 2-amino-4-carbonyl-6-methylpyrimidine was mixed with 12 parts of hexamethylene diisocyanate at 100 °C React for 18 hours under the protection of an inert gas. After the reaction is completed, cool to room temperature, add petroleum ether to precipitate, suction filter, and wash to obtain a white powder, and transfer it to a vacuum oven at 30°C to dry for 12 hours to obtain a UPy-NCO capping agent whose terminal group is isocyanate ; In molar fractions, mix 1 part of UPy-NCO with 1.2 parts of 2-amino-2-methyl-1,3-propanediol and 150 parts of dry chloroform, and reflux for 6 hours under the protection of nitrogen. After the reaction was complete, it was precipitated with petroleum ether, suction filtered and washed to obtain a chain extender with multiple hydrogen bond groups in the form of a white solid, which was dried in a vacuum oven with a yield of 68%.

[0060] Prepa...

Embodiment 2

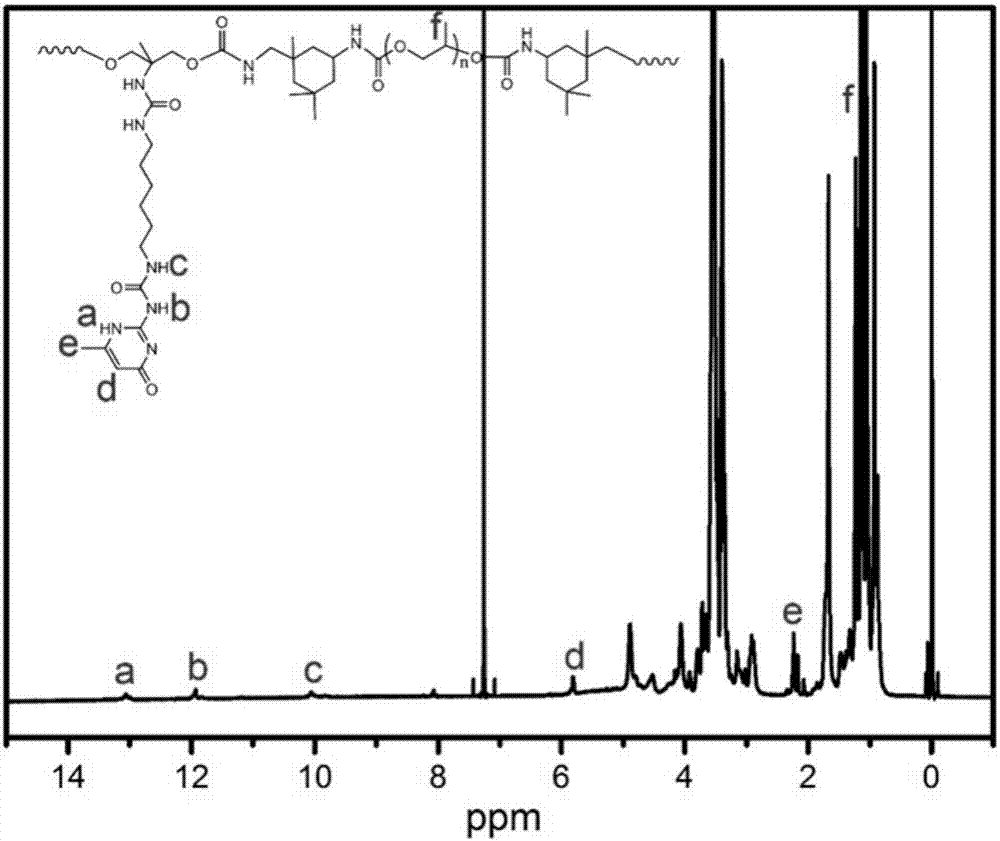

[0065] Synthesis of UPy-NCO end-capping agent and corresponding chain extender: in mole fraction, 1 part of 2-amino-4-carbonyl-6-methylpyrimidine was mixed with 15 parts of dicyclohexylmethane diisocyanate at 100 °C React for 15 hours under the protection of an inert gas. After the reaction is completed, cool to room temperature, add cyclohexane to precipitate, suction filter, and wash to obtain a white powder, and transfer it to a vacuum oven at 30°C to dry for 12 hours to obtain UPy-NCO capped with isocyanate. agent; in mole fractions, mix 8 parts of UPy-NCO capping agent with 2 parts of 2-amino-1,3-propanediol and dry N,N-dimethylformamide, and reflux for 8 hours under nitrogen protection. After the reaction was complete, it was precipitated with petroleum ether, suction filtered and washed to obtain a white solid of multiple hydrogen bond group chain extender, which was dried in a vacuum oven with a yield of 67%.

[0066] Preparation of self-healing polymer material: In te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com