A kind of nano-starch-based microgel microsphere and its preparation method and application

A technology of nano-starch and microspheres, which is applied in chemical instruments and methods, pharmaceutical formulations, and other chemical processes. It can solve the problems of inability to control the particle size of starch microspheres, low preparation efficiency, and complex starch microspheres. Achieve controllable microsphere size, high biocompatibility, and avoid microsphere loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

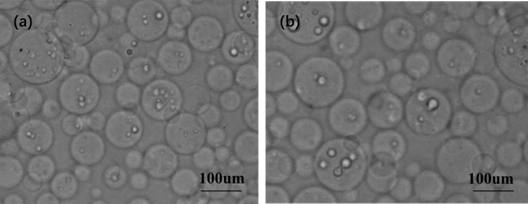

[0032] A preparation method of nano-starch-based microgel microspheres, comprising the following steps:

[0033] Using nano-starch as raw material, adding it into water to prepare nano-starch dispersion, wherein water can be distilled water or deionized water; adding emulsifier to organic solvent to obtain oil phase; adding nano-starch dispersion to oil phase , to obtain a water-in-oil type nano-starch inverse emulsion; and then adding a cross-linking agent and an alkali into the starch inverse emulsion, stirring, and carrying out a cross-linking reaction.

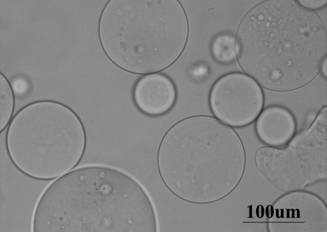

[0034] As a further embodiment, the reacted product is also separated, washed and sieved to obtain nano-starch-based microgel microspheres with a particle size of 75-250 microns.

[0035] The reversed-phase suspension method is to dissolve starch powder in water, and as the water phase, disperse it into an organic solution containing an appropriate amount of emulsifier to form a uniform, stable and transparent microemulsio...

Embodiment 1

[0045] Preparation of cross-linked nano-starch-based microgel microspheres

[0046] Weigh 5g of nano-starch powder, add it to 50g of deionized water, and stir to form a 10% (w / w) nano-starch dispersion; weigh 50ml of n-octane, add 2g of emulsifier Span 80, stir to dissolve, and then use a mechanical The stirring device conducts high-speed stirring at a stirring speed of 800 rpm, and the temperature is raised to 50 ° C during this process; the nano-starch dispersion is poured into the high-speed stirring n-octane while it is still hot, maintained at 50 ° C, and high-speed stirring for 30min; Keep at 50 °C, add 2 ml of 2 mol / L NaOH solution, 2 g of cross-linking agent epichlorohydrin, and stir at a reduced speed, with a stirring speed of 250 rpm, and cross-linking reaction for 0.5 h; then increase the reaction temperature to 95 ° C and continue the reaction for 2 h; The heating is removed, and the solution is layered after standing, and the lower layer is nano-starch-based micro...

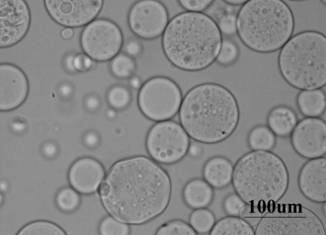

Embodiment 2

[0048] Preparation of cross-linked nano-starch-based microgel microspheres

[0049] Weigh 2.5g of nano-starch powder, add it to 50g of deionized water, and stir to form a 5% (w / w) nano-starch dispersion; weigh 50ml of n-octane, add 2g of emulsifier Span 85, stir to dissolve, and then use The mechanical stirring device conducts high-speed stirring at a stirring speed of 1000 rpm, and the temperature rises to 65 °C at the same time during this process; the completely dissolved nanostarch aqueous solution (with high viscosity) is poured into the high-speed stirring n-octane while hot, and maintained at 65 °C, Stir at high speed for 30min; reduce the temperature of the reaction system to 50°C, add 2ml of 2mol / L NaOH solution and 2g of epichlorohydrin, stir at a reduced speed, stir at a speed of 250rpm, and conduct cross-linking reaction for 0.5h; then increase the reaction temperature to 95°C, The reaction was continued for 2 hours; the heating was removed, the solution was layere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com