Sputtering target for forming transparent oxide film and manufacturing method thereof

A technology of transparent oxide and manufacturing method, which is applied in optical recording/reproduction, sputtering coating, optical record carrier manufacturing, etc., and can solve problems such as inability to implement sputtering, frequent occurrence, and abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

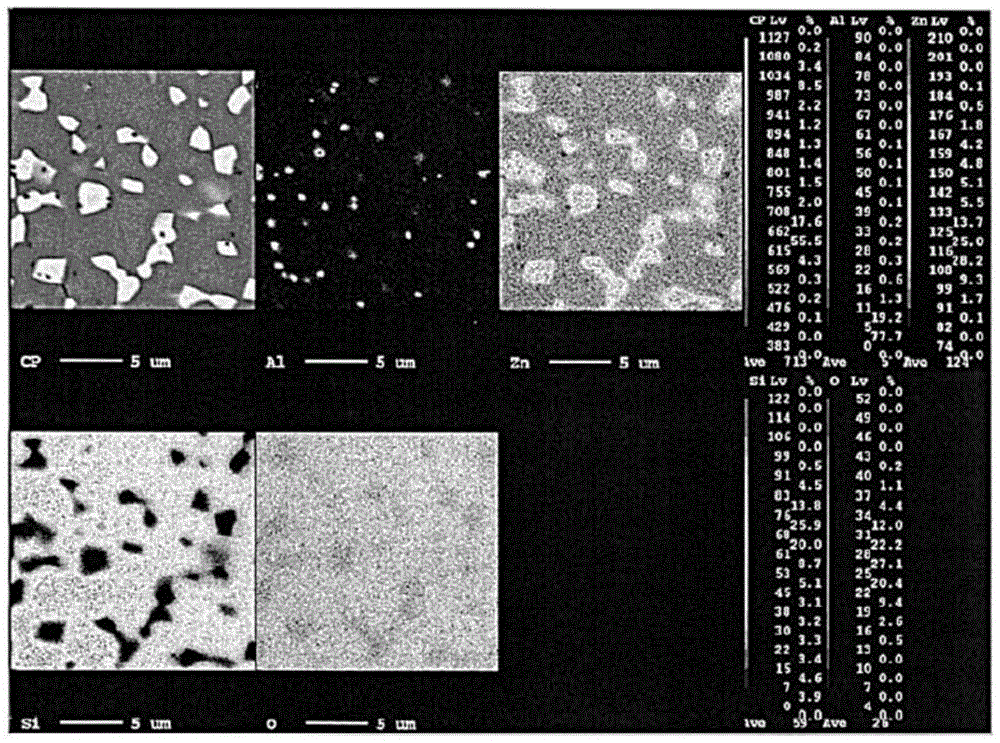

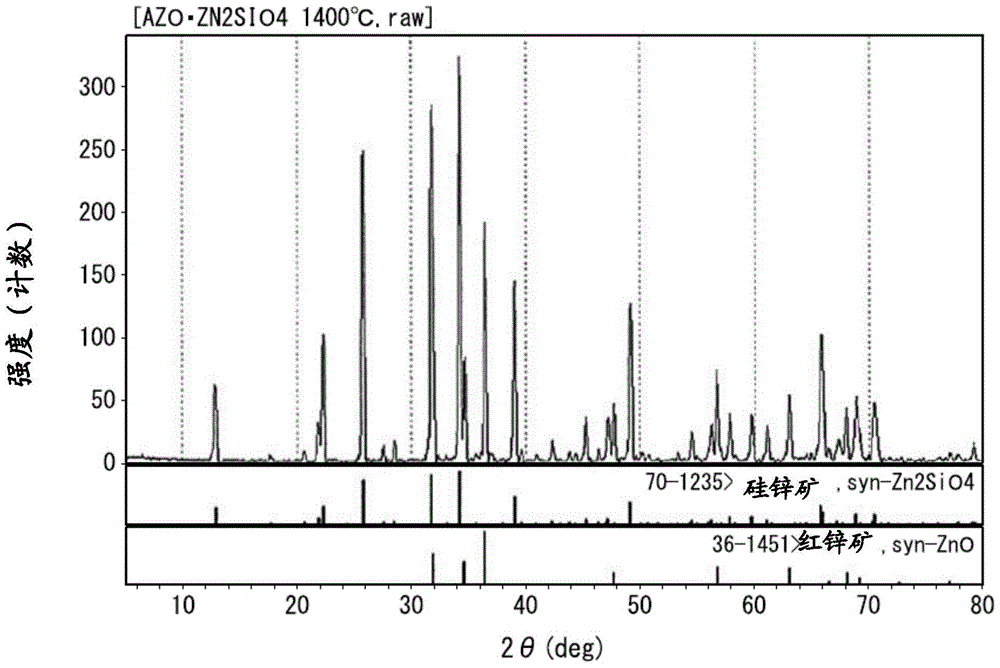

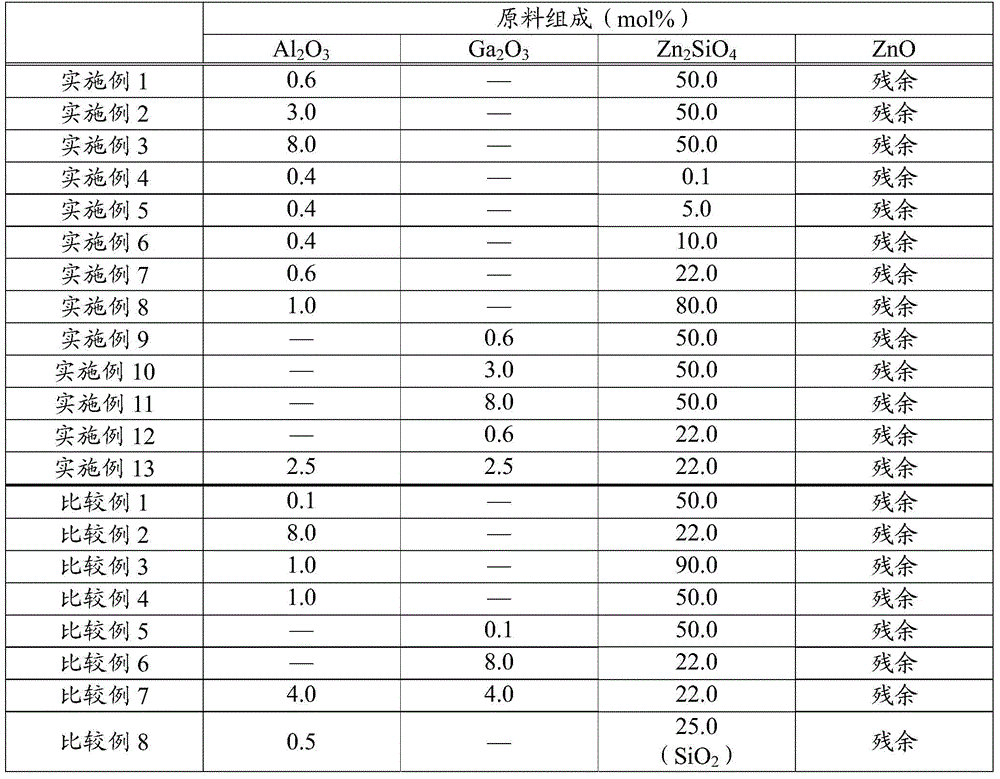

[0052] In the first example, when producing a sputtering target for forming a transparent oxide film, first, raw material powders of zinc oxide powder and silicon oxide powder are fired to produce a calcination body composed of a composite oxide of Zn and Si , and pulverize the calcined body to obtain a composite oxide powder of Zn and Si. Next, the obtained composite oxide powder of Zn and Si, zinc oxide powder, and a mixed powder of one or both of aluminum oxide powder and gallium oxide powder are molded and then fired to obtain a fired body. It is machined to produce a sputtering target. About this manufacture, it will describe in detail below.

[0053] 1) A case where a mixed powder of Zn and Si composite oxide powder, zinc oxide powder, and alumina powder is used will be described.

[0054] First, zinc oxide (chemical formula: ZnO, D 50 =1μm), silicon oxide (chemical formula: SiO 2 ,D 50 =2.0μm) each raw material powder to become ZnO:SiO 2 =2:1 (molar ratio) mode is...

no. 2 Embodiment

[0104] In the above-mentioned first embodiment, when manufacturing a sputtering target for forming a transparent oxide film, first, a mixture of zinc oxide (ZnO) powder and silicon oxide (SiO 2 ) The raw material powder of the powder is fired and then pulverized and fired, and is composed of a composite oxide of Zn and Si (Zn 2 SiO 4 ) composed of a calcined body, and pulverize the calcined body to obtain a composite oxide of Zn and Si (Zn 2 SiO 4 )powder. Second, in the obtained Zn 2 SiO 4 powder, ZnO powder, and alumina (Al 2 o 3 ) powder and gallium oxide (Ga 2 o 3 ) powders or mixed powders of two kinds of powders are molded and fired to obtain a fired body, and the fired body is machined to manufacture a sputtering target.

[0105] In the second example, in the manufacturing method of the above-mentioned sputtering target for forming a transparent oxide film, as shown in Table 4, the flexural strength and thermal conductivity related to the fired body of the mold...

no. 3 Embodiment

[0132] In the manufacturing method of the sputtering target for forming a transparent oxide film according to the above-mentioned first embodiment, pre-fired ZnO powder and SiO 2 Powder Zn and Si composite oxide (Zn 2 SiO 4 ) as the raw material powder, the mixed powder of the raw material composition shown in Table 1 was fired, but in the third embodiment, the production process of the calcined body was omitted, and Zn 2 SiO 4 powder, while using a large amount of ZnO powder and SiO 2 powder as raw material powder. In the manufacturing method of the sputtering target for forming a transparent oxide film according to the third embodiment described above, SiO 2 Powder, Al 2 o 3 Powder and ZnO powder are used as raw material powders. ZnO powder and SiO in raw powder 2 powder, the ZnO powder and SiO powder with the particle size shown in Table 6 are used 2 powder. In addition, as shown in Table 6, the firing temperature and firing retention time, which affect the flexur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com