Substance for desulfurization as well as preparation method and application thereof

A substance and formula technology, applied in chemical instruments and methods, chemical/physical processes, removal of gas pollutants, etc., can solve problems such as increased device start-up time, desulfurization agent overheating, reactor damage, etc., to save enterprises Cost, efficient removal, low replacement frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The content of iron element in the material for desulfurization is 0.1 mg / g, the content of copper element is 0.1 mg / g, and the average particle size of the material for desulfurization is 2.0 mm.

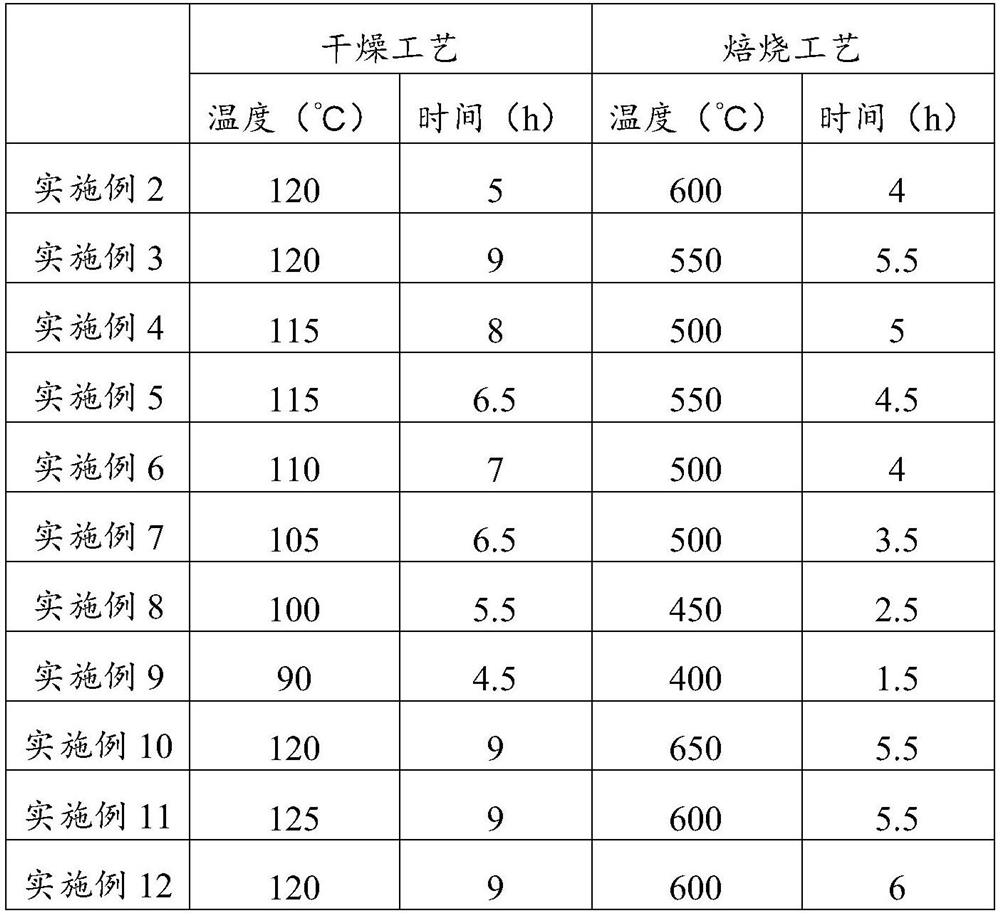

Embodiment 2-12

[0041] Table 1

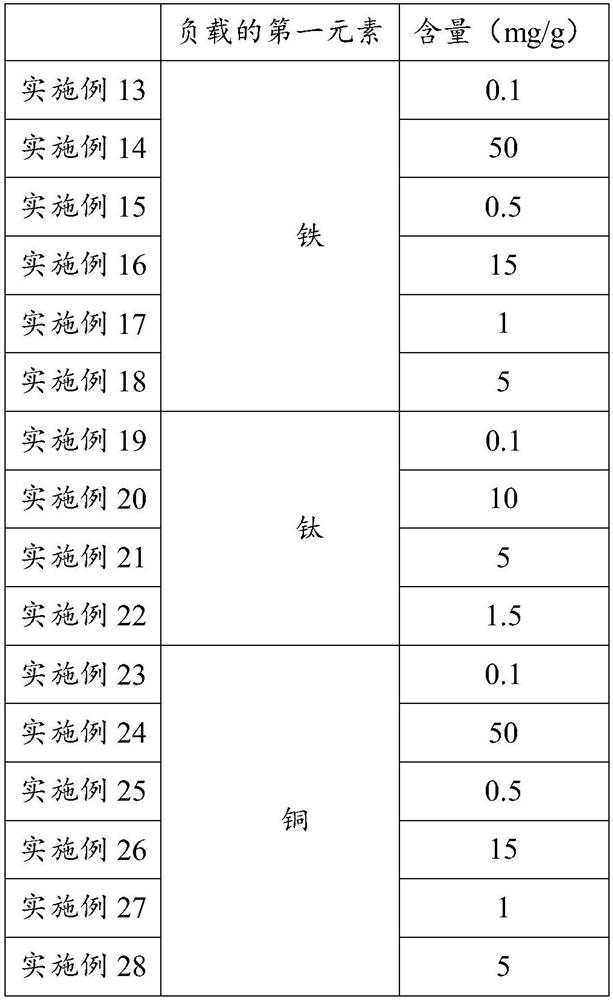

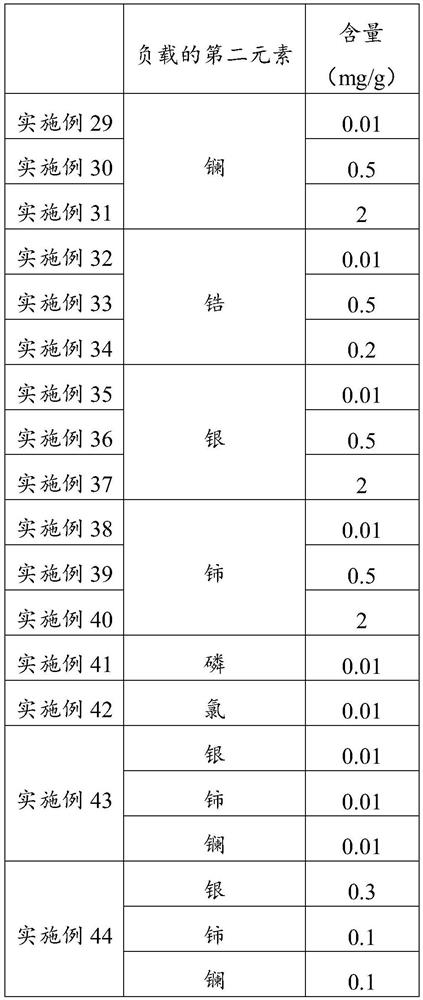

Embodiment 13-28

The elements of the first type supported in this part of the embodiments individually include one of iron, copper or titanium.

[0043] Referring to Example 1, according to the specific element formulation to be loaded, any acceptable form of compound is selected as a precursor to prepare a corresponding first impregnating liquid.

[0044] For example, when loading 0.1 mg / g of iron, weigh 43.2 mg of ferric nitrate and dissolve it in 100 ml of water to obtain the first immersion solution;

When 0.1 mg / g copper element is loaded, 29.6 mg of copper nitrate is weighed and dissolved in 100 ml of water to obtain another first dipping solution; and so on.

[0045] The content of the loaded elements in the materials for desulfurization prepared in each example is shown in the following table.

[0046] Table 2

For the above-mentioned embodiment, the investigation experiment of desulfurization performance was carried out, and found according to the experimental results:

(1) Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com