Method for preparing vanadium disulphide nano powder

A nano-powder, vanadium disulfide technology, applied in chemical instruments and methods, nanotechnology, vanadium compounds, etc., can solve the problem of difficult to obtain VS2 pure phase, high cost of preparation of vanadium disulfide powder, difficulty in large-scale production, etc. problems, to achieve the effect of low cost, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

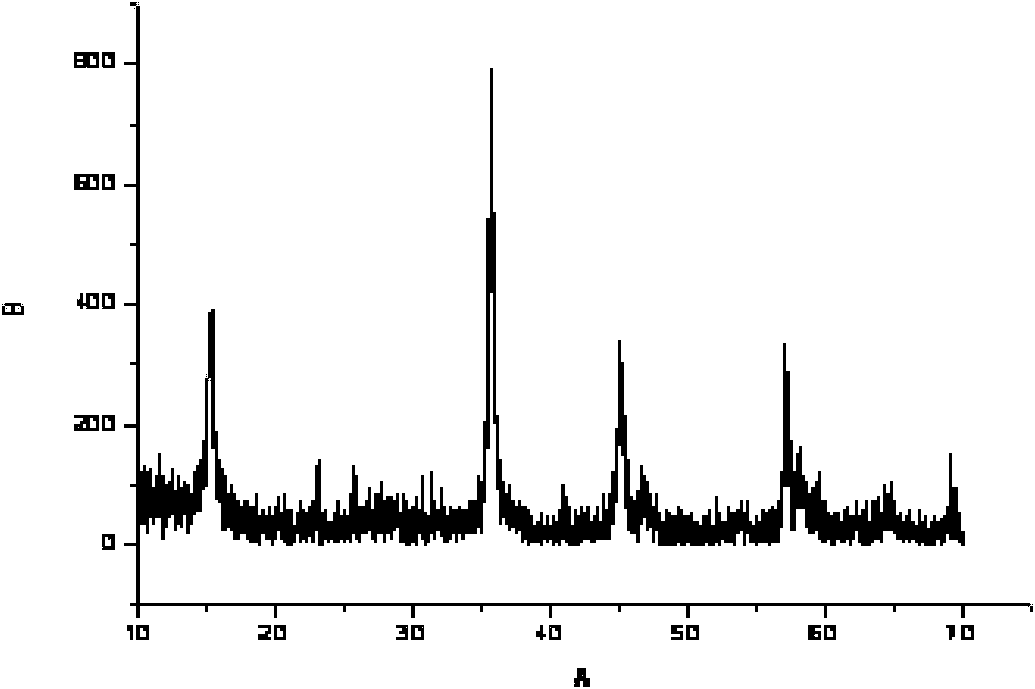

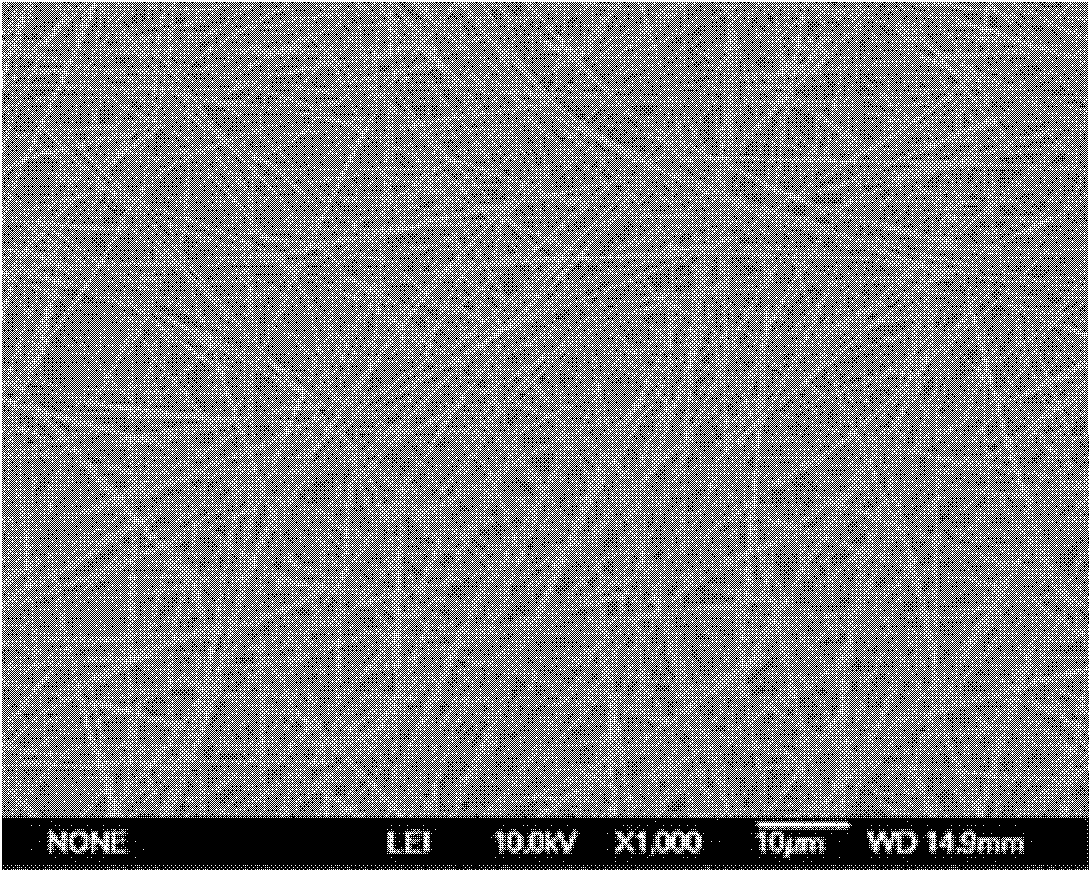

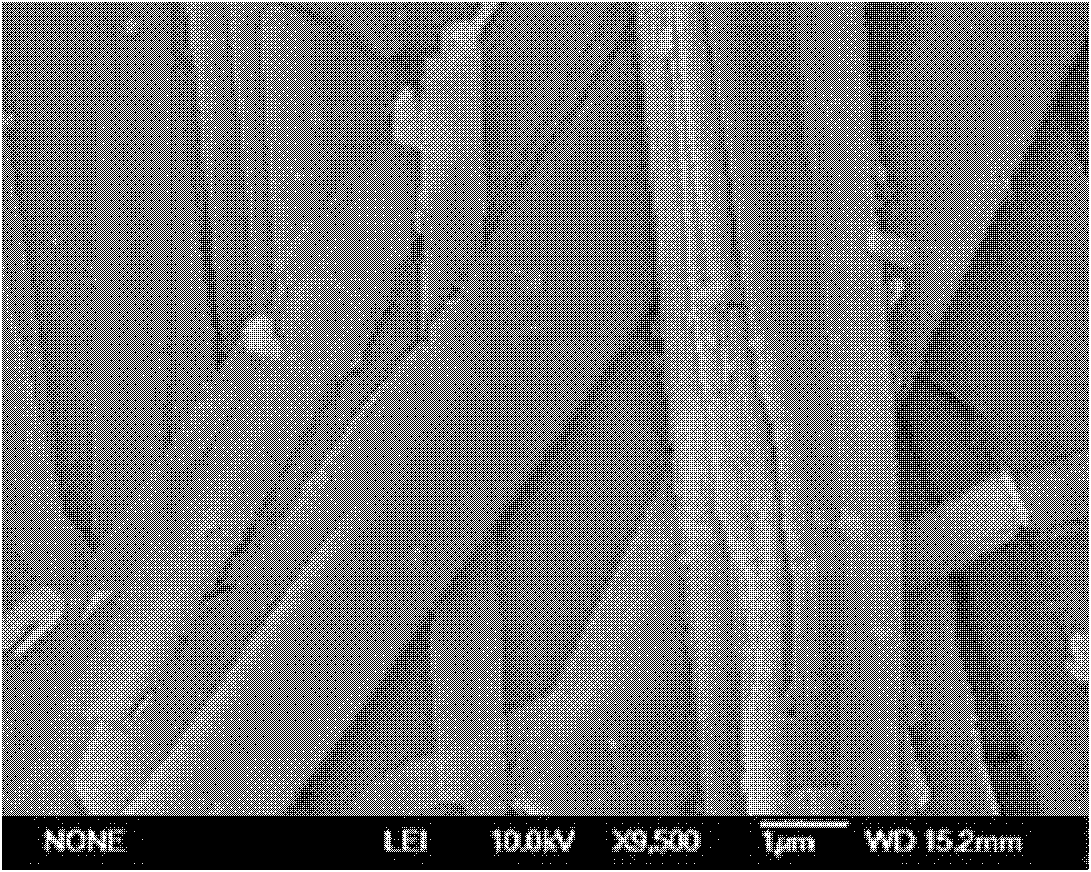

[0039] Hydrothermal synthesis of vanadium disulfide uniform ultra-long nanowires: Take a laboratory hydrothermal reaction kettle, which has a stainless steel shell and a polytetrafluoroethylene liner. Add 3mmol ammonium metavanadate (NH 4 VO 3 ), and added 40ml of water, and then added 1ml of 1mol / L ammonia water to completely dissolve ammonium metavanadate in the alkaline aqueous solution, then added 15mmolTAA, and stirred for 10min. After sealing the hydrothermal autoclave, place it in an oven at 180° C. for 20 h. After natural cooling, the obtained product was washed with deionized water and absolute ethanol to remove possible impurities. Such as figure 1 as shown, figure 1 For the XRD analysis figure of the vanadium disulfide prepared in this embodiment, all X-ray powder diffraction peaks can be indexed as VS 2 powder, and no other impurity peaks appear, so what is synthesized in Example 1 is high-purity VS 2 nanomaterials. figure 2 The FE-SEM photographs of the va...

Embodiment 2

[0041]Hydrothermal synthesis of vanadium disulfide uniform ultra-long nanowires: add 2mmol vanadium pentoxide (V 2 o 5 ), and add 30ml of water, then add 10ml of 1mol / L ammonia water to completely dissolve vanadium pentoxide in the alkaline aqueous solution, then add 12mmolTAA, and stir for 10min. After sealing the hydrothermal autoclave, place it in an oven at 200° C. for 25 h. After natural cooling, the obtained product was washed with deionized water and absolute ethanol to remove possible impurities.

Embodiment 3

[0043] Hydrothermal synthesis of vanadium disulfide uniform ultra-long nanowires: Add 2mmol sodium orthovanadate and 40ml water to the polytetrafluoroethylene liner of a 50ml hydrothermal reaction kettle, then add 14mmol copper reagent, and stir for 10min. After sealing the hydrothermal autoclave, place it in an oven at 150° C. for 30 h. After natural cooling, the obtained product was washed with deionized water and absolute ethanol to remove possible impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com