Copper mine tailing slag porous ceramic material and preparation method thereof

A technology for porous ceramics and tailing slag, which is applied in the field of copper mine tailings slag porous ceramic materials and preparation to achieve the effects of enhancing compressive strength, large utilization and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

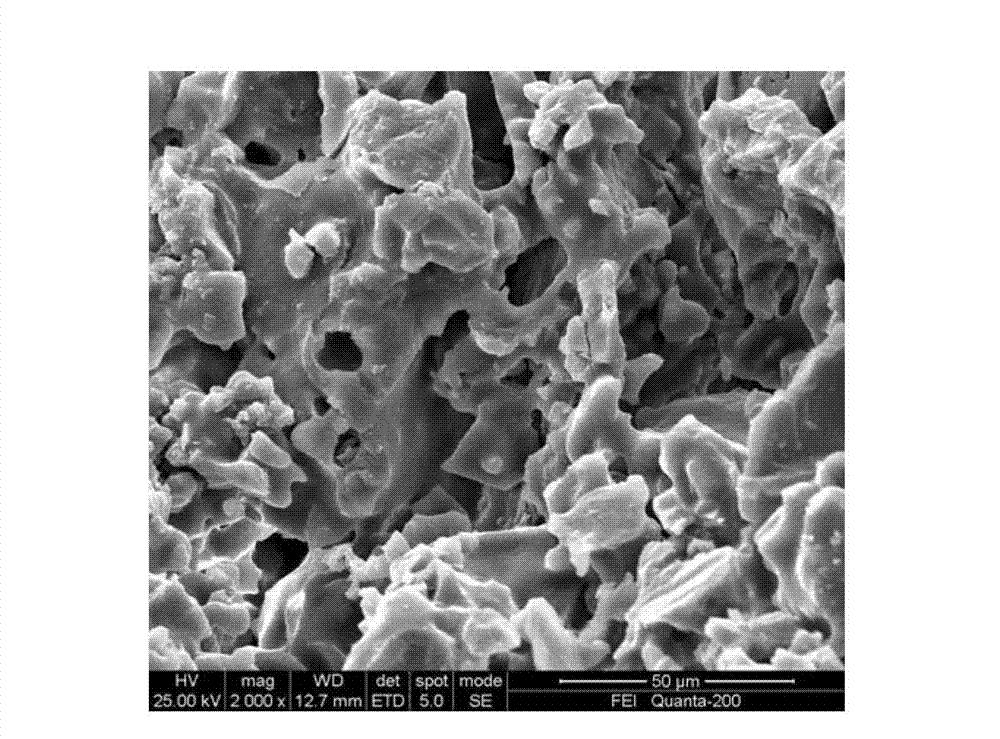

Image

Examples

Embodiment 1

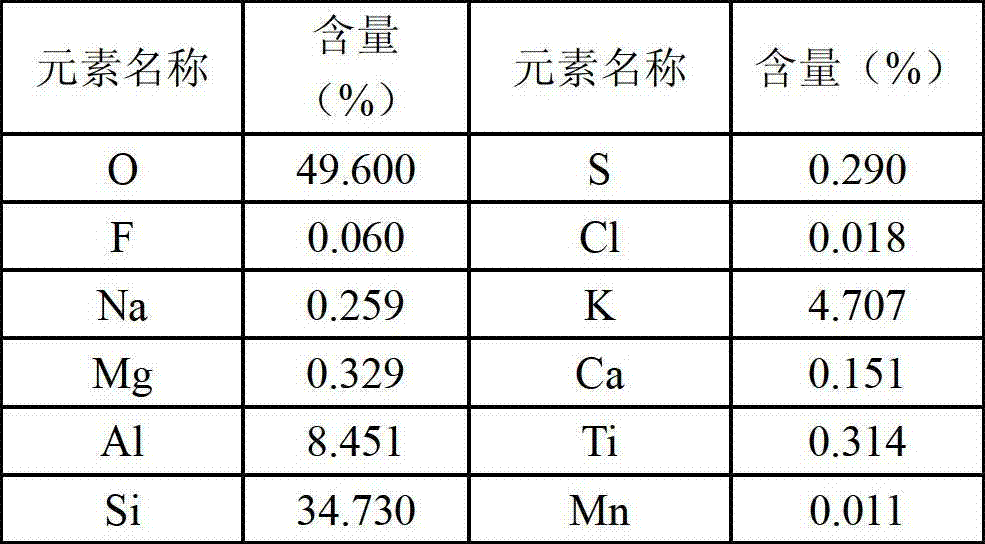

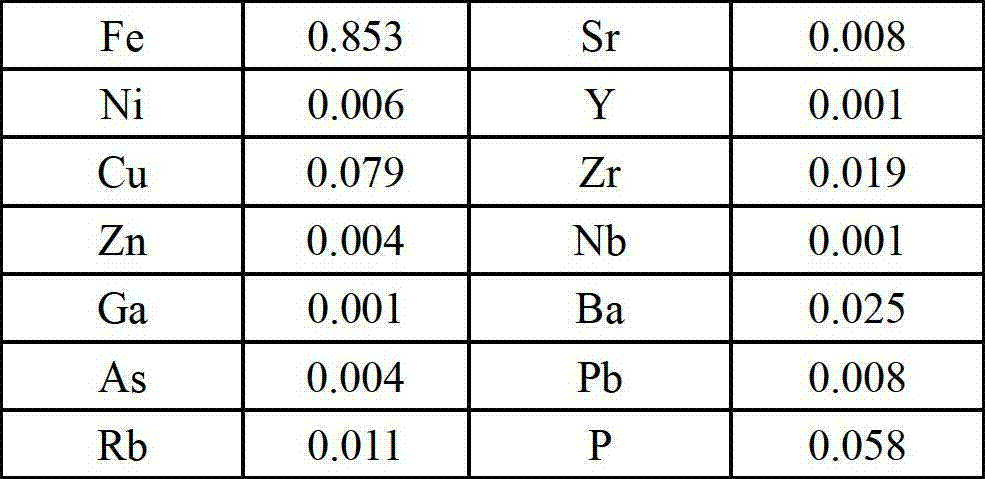

[0032] Example 1 Copper ore flotation tailings are used as raw material, and kaolin is used as binder. The copper ore tailings were taken from the tailings dam of the Dexing Copper Mine, and analyzed by XRF. The results are shown in Table 1:

[0033] Table 1

[0034]

[0035]

[0036] Take 100 parts of beneficiation tailings from Dexing Copper Mine, 30 parts of carbon powder, 20 parts of kaolin, and 3 parts of feldspar, mix them evenly, put them into a steel mold, press for 3 minutes under a pressure of 8MPa, take out the green body, and let it dry naturally , put it into a high-temperature electric furnace, raise the temperature from room temperature to 1100° C. at a rate of 5° C. / min, keep it for sintering for 1 hour, take it out after cooling, and obtain porous ceramics. The apparent porosity of porous ceramics is 41.07%, the water absorption rate is 30.68%, and the bulk density is 1.78g / cm 3 , the compressive strength is 2.7MPa, the acid resistance is 96.82%, and ...

Embodiment 2

[0037] Example 2 Copper ore flotation tailings are used as raw material (same as Example 1), and sodium lignosulfonate is used as binder.

[0038] Take 100 parts of Dexing copper mine beneficiation tailings, 30 parts of carbon powder, 3 parts of feldspar, 15 parts of sodium lignosulfonate, mix them evenly, put them into a steel mold, press for 3 minutes under a pressure of 8 MPa, and take out the green body , after natural air-drying, put it into a high-temperature electric furnace, raise the temperature from room temperature to 1100°C at a rate of 5°C / min, keep it for sintering for 1 hour, take it out after cooling, and obtain porous ceramics. The apparent porosity of porous ceramics is 56.93%, the water absorption rate is 52.78%, and the bulk density is 1.09g / cm 3 , the compressive strength is 15.8MPa, the acid resistance is 98.87%, and the alkali resistance is 99.13%. It can be found that using sodium lignosulfonate as a binder under the same conditions, compared with usin...

Embodiment 3

[0039] Example 3 Copper ore flotation tailings are used as raw material (same as Example 1), and water glass is used as binder.

[0040]Take 100 parts of Dexing copper mine beneficiation tailings, 30 parts of carbon powder, 5 parts of serpentine, and 25 parts of water glass, mix them evenly, put them into a steel mold, press for 3 minutes under a pressure of 10 MPa, take out the green body, and naturally After air-drying, put it into a high-temperature electric furnace, raise the temperature from room temperature to 1080°C at a rate of 3°C / min, keep it warm for sintering for 80min, take it out after cooling, and obtain porous ceramics. The apparent porosity of porous ceramics is 39.76%, the water absorption rate is 28.01%, and the bulk density is 1.91g / cm 3 , the compressive strength is 1.48MPa, the acid resistance is 98.65%, and the alkali resistance is 98.27%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com