Method for preparation of nitrogen doped porous nano carbon material with biomass as carbon source by gel process

A nano-carbon material, nitrogen-doped technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of easy falling off of metal particles, poor energy storage performance, low specific surface, etc., to increase the storage charge. capacity, increased added value, and the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

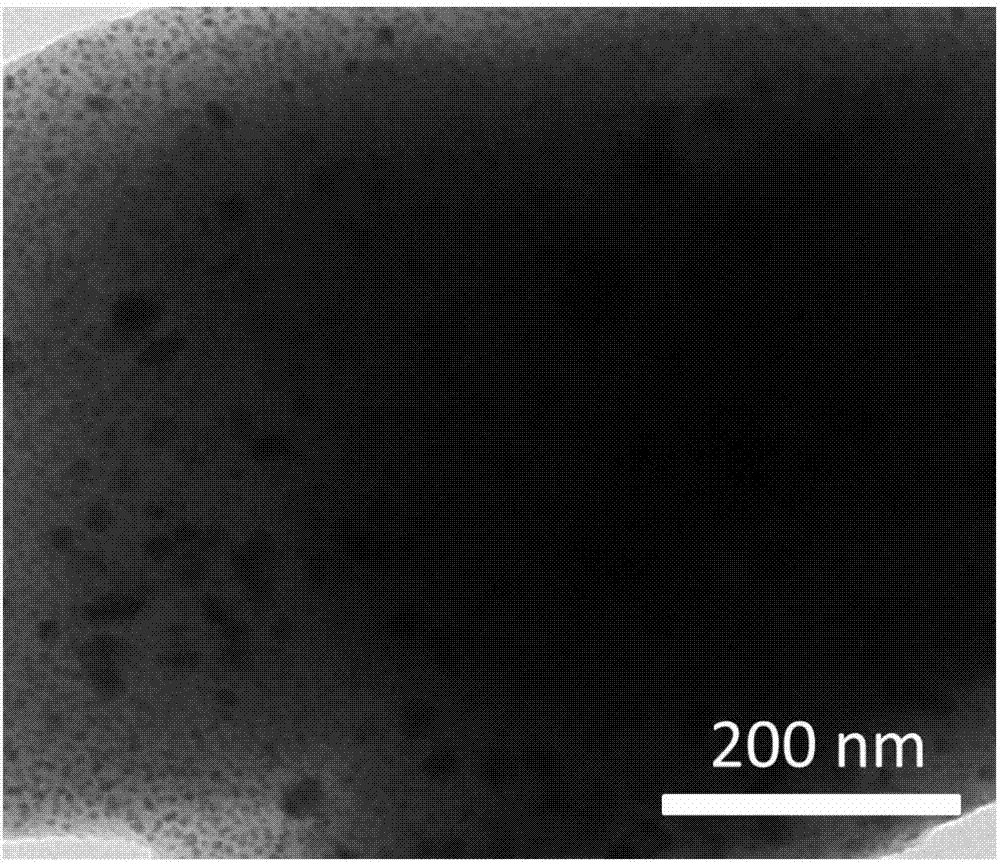

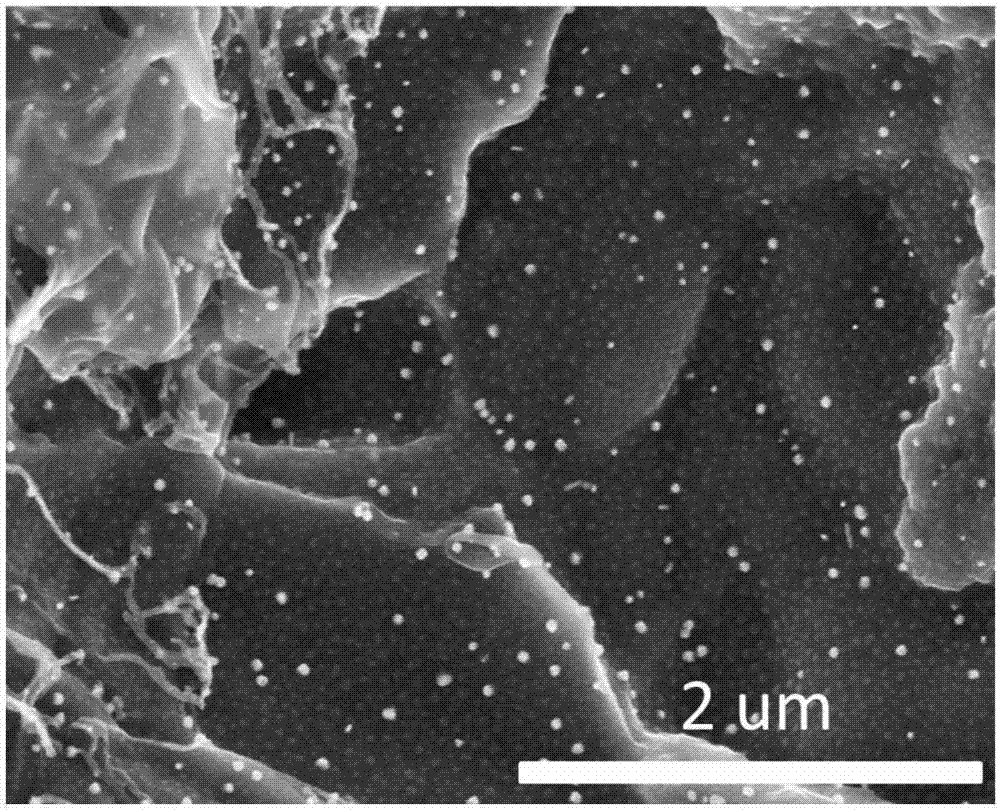

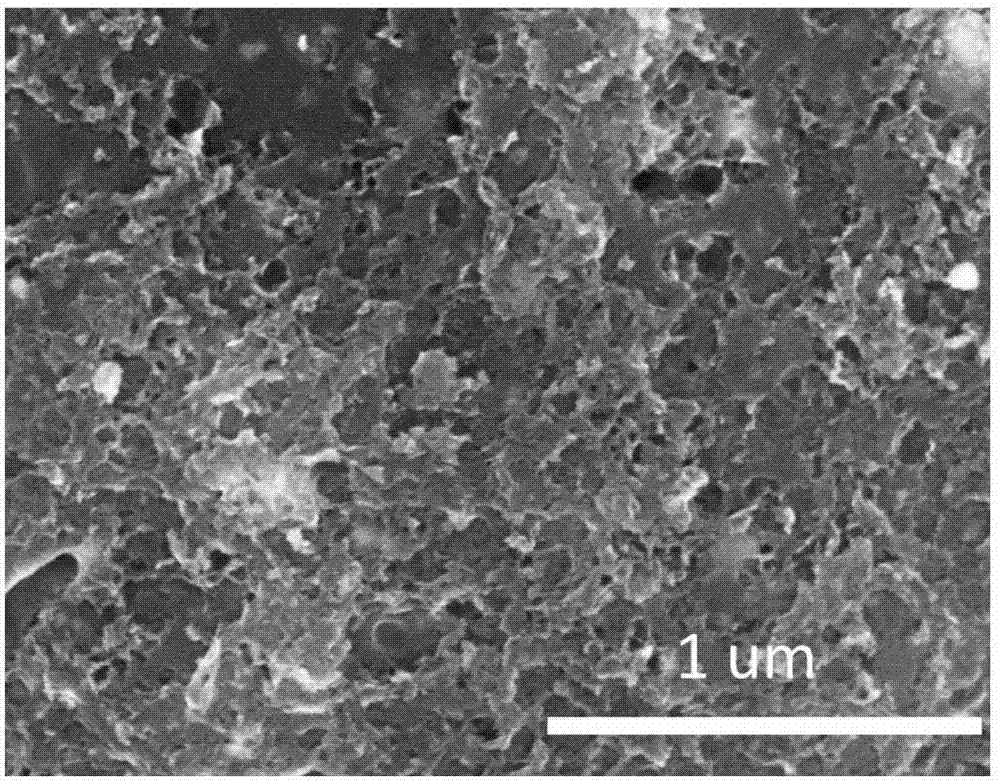

[0044] (1) Weigh a certain amount of bean dregs, soak them in ethanol for 24 hours at room temperature, and then soak them in deionized water for 10 hours; grind the soaked bean dregs and water into soybean milk at a mass ratio of 1:10, and the temperature is at 80°C , adding nickel nitrate to form tofu gel;

[0045] (2) Freeze-dry the tofu gel obtained in step (1), wherein the conditions of the freeze-dryer are: the temperature of the freeze-dryer is -55°C, and the air pressure is 0-150Pa;

[0046](3) Put the freeze-dried tofu gel in step (2) into a high-temperature furnace for heat treatment for pre-carbonization, and continuously feed nitrogen; wherein, the heat treatment conditions of the high-temperature furnace are: in the high-temperature furnace, at 5°C / min The heating rate was raised to 750°C, the nitrogen flow rate was 30mL / min, and the temperature was kept for 3h;

[0047] (4) Disperse the pre-carbonized material obtained in step (3) in water, add an activator KOH,...

Embodiment 2

[0051] Similar to Example 1, the difference is that the coagulant selected in this example is cobalt nitrate.

[0052] The nitrogen-doped porous nano-carbon material prepared in the above examples was characterized by XRD, as Figure 5 As shown, the diffraction peaks appearing at the 2θ angle of 22.44° on the map are the diffraction peaks of the graphite (002) crystal plane; On the Co[1 1 1], Co[2 0 0], Co[2 2 0] crystal planes, it shows that Co exists in a face-centered cubic structure, and it also proves that the product contains both carbon and cobalt.

Embodiment 3

[0054] Similar to Example 1, the difference is that the coagulant selected in this example is copper nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com