Preparation method of manganese dioxide/ carbon microspheres composite material and application of composite material serving as supercapacitor electrode material

A supercapacitor, manganese dioxide technology, applied in the field of electrochemical materials and composite materials, can solve the problems of poor cycle stability, low electrochemical utilization, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

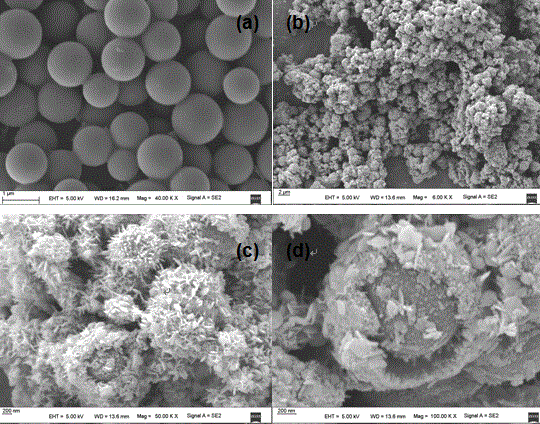

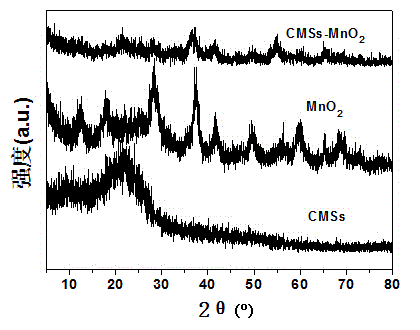

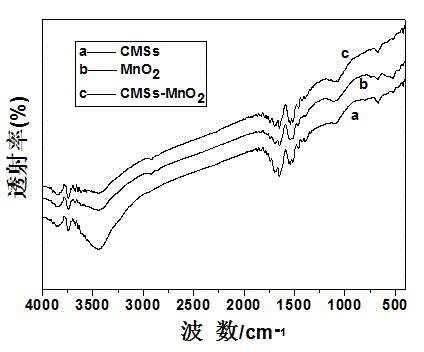

[0047] (1) Manganese dioxide / carbon microspheres (MnO 2 / CMSs) composites

[0048] Add 6 g of glucose powder into a beaker containing 100 mL of deionized water, stir for 1 h, then place the mixed solution in an autoclave, and conduct a hydrothermal reaction at 180 °C for 24 h, and after the autoclave is cooled to room temperature, pump the product Filter, wash several times with absolute ethanol and deionized water, and vacuum dry at 60°C for 12 hours to obtain carbon microspheres (CMSs). Then 0.86g KMnO 4 and 0.15g CMSs were added to 100mL deionized water and stirred continuously. After the mixture was stirred for 5min, 1mL of concentrated sulfuric acid was added to make the pH of the reaction system 1~2. Stir at room temperature for 30min, and then the mixture was heated to 80 ℃, reflux for 1h; after the reaction system was cooled to room temperature, suction filtered, the product was washed several times with absolute ethanol and deionized water, and dried at 60°C for 12h...

Embodiment 2

[0053] 1) Manganese dioxide / carbon microspheres (MnO 2 / CMSs) composites

[0054] Add 5.5% glucose powder into a beaker filled with 100mL deionized water, stir for 1h, then place the mixed solution in an autoclave, and conduct a hydrothermal reaction at 185°C for 12h. After the autoclave is cooled to room temperature, filter the product with suction 1. Washing several times with absolute ethanol and deionized water, and drying in vacuum at 60° C. for 12 hours to obtain carbon microspheres (CMSs). Then 0.9g KMnO 4 and 0.15g CMSs were added to 100mL deionized water and stirred continuously. After the mixture was stirred for 5min, 1mL of concentrated sulfuric acid was added to make the pH of the reaction system 1~2. Stir at room temperature for 50min, and then the mixture was heated to 80 ℃, reflux for 1h; after the reaction system was cooled to room temperature, suction filtered, the product was washed several times with absolute ethanol and deionized water, and dried at 60°C ...

Embodiment 3

[0059] 1) Manganese dioxide / carbon microspheres (MnO 2 / CMSs) composites

[0060]Add 6 g of glucose powder into a beaker with 100 mL of deionized water, stir for 2 h, then place the mixed solution in an autoclave, and conduct a hydrothermal reaction at 180 ° C for 24 h. After the autoclave is cooled to room temperature, the product is extracted Filter, wash several times with absolute ethanol and deionized water, and vacuum dry at 60°C for 12 hours to obtain carbon microspheres (CMSs). Then 0.8g KMnO 4 and 0.16g CMSs were added to 100mL deionized water and stirred continuously. After the mixture was stirred for 5min, 1mL of concentrated sulfuric acid was added to make the pH of the reaction system 1~2. Stir at room temperature for 30min, and then the mixture was heated to 80 ℃, reflux for 1h; after the reaction system was cooled to room temperature, suction filtered, the product was washed several times with absolute ethanol and deionized water, and dried at 60°C for 12h to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com