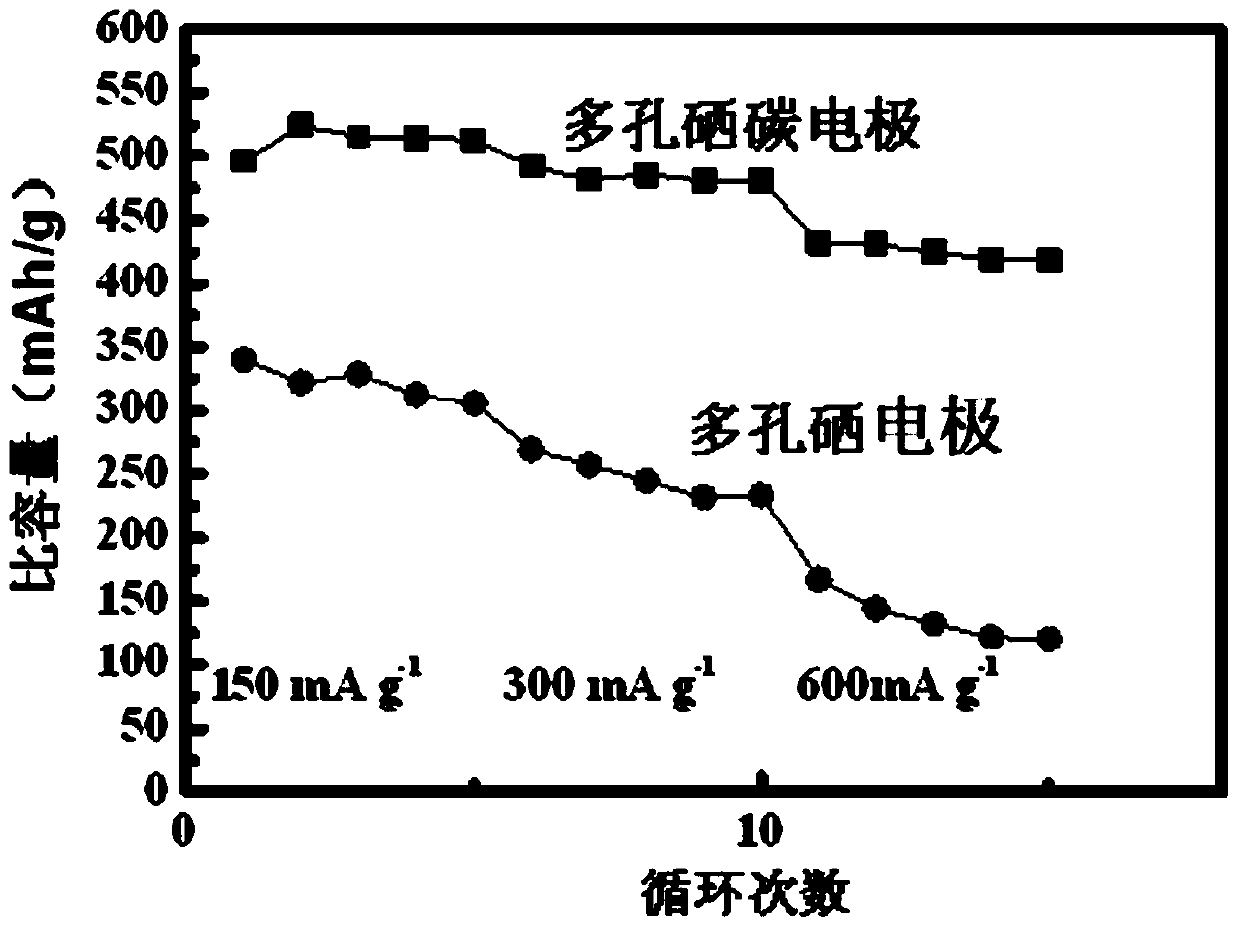

Preparation method of selenium-carbon electrode material with porous structure and application of selenium-carbon electrode material

A technology of electrode material and porous structure, applied in the field of electrochemistry, can solve the problems of not being suitable for large-scale production, etc., and achieve good electrochemical performance, good rate performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The synthetic method of porous selenium carbon electrode material:

[0031] (1) Selenium-carbon compound: mix graphene, elemental selenium and nano-calcium carbonate, add ball milling tank for 36 hours, and the rotating speed of the ball-milling tank is 5000rpm; wherein, the mass ratio of graphene and elemental selenium is 1:50, and nano-calcium carbonate The mass ratio with elemental selenium is 1:1;

[0032] (2) The product of step (1) is heat-treated at 250°C for 20h under an inert gas atmosphere; cooled and ground for 2h; then treated in 50% concentrated hydrochloric acid for 12h to remove nano-calcium carbonate;

[0033] (3) After the product of step (2) is washed and dried, it is heat-treated at 250° C. for 3 hours under an argon atmosphere to obtain the final product.

Embodiment 2

[0035] The synthetic method of porous selenium carbon electrode material:

[0036] (1) Selenium-carbon composite: mix graphene, elemental selenium and nano-calcium carbonate, add it into a ball milling tank for ball milling for 4 hours, and the rotating speed of the ball-milling tank is 30000rpm; wherein, the mass ratio of carbon source and elemental selenium is 1:100, and nano-calcium carbonate The mass ratio with elemental selenium is 1:10;

[0037] (2) The product of step (1) is heat-treated at 100° C. for 32 h under an inert gas atmosphere; cooled and ground for 1 h; then treated in 50% concentrated hydrochloric acid for 2 h to remove nano-calcium carbonate;

[0038] (3) After the product of step (2) is washed and dried, it is heat-treated at 100° C. for 5 hours under a nitrogen atmosphere to obtain the product.

Embodiment 3

[0040] The synthetic method of porous selenium carbon electrode material:

[0041] (1) Selenium-carbon composite: mix carbon nanotubes, elemental selenium and nano-calcium carbonate, and add them to a ball milling tank for ball milling for 78 hours. The mass ratio of calcium and elemental selenium is 10:1;

[0042] (2) The product of step (1) is heat-treated at 500°C for 4h under an inert gas atmosphere; cooled and ground for 4h; then treated in 50% concentrated hydrochloric acid for 24h to remove nano-calcium carbonate;

[0043] (3) After the product of step (2) is washed and dried, it is then heat-treated at 500° C. for 2 hours under a carbon monoxide atmosphere to obtain the product. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com