Modified nanometer calcium carbonate and method for making same and uses

A nano-calcium carbonate and modified technology, applied in the field of nano-materials, can solve the problems of difficult industrialization and high cost, achieve broad industrial application prospects, reduce agglomeration, and enhance the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 8.8 grams of triethylene glycol monocinnamate (A) to 100 grams of nano-calcium carbonate dry powder, and react with high-speed stirring in a flask at 100° C. for 1 hour. Cool to room temperature to obtain modified nano-calcium carbonate A-CaCO 3 .

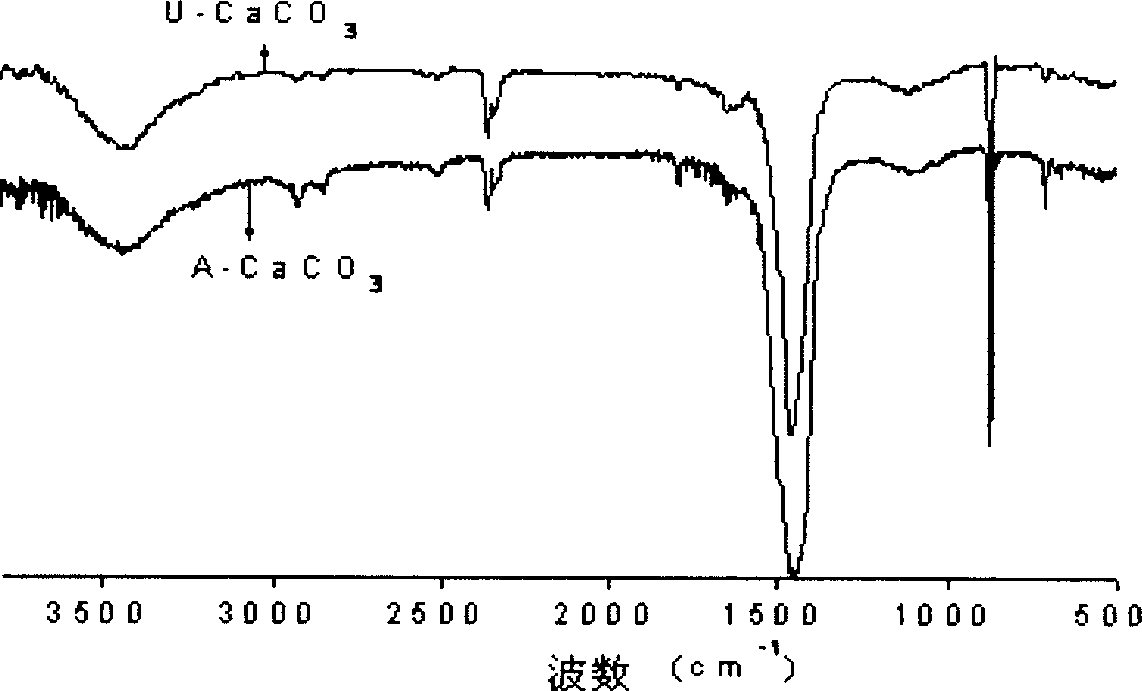

[0030] After the modified nano-calcium carbonate and the unmodified nano-calcium carbonate are extracted by organic solvent, the infrared spectrum test is carried out, such as figure 1 As shown, organic group peaks still appear after the extraction of modified nano-calcium carbonate, and the infrared spectra of unmodified nano-calcium carbonate after extraction are completely consistent, indicating that the organic matter on the surface of modified calcium carbonate forms a chemical combination with calcium carbonate, while There is no change on the surface of unmodified calcium carbonate.

[0031] Unmodified nano calcium carbonate (U-CaCO 3 ) The sedimentation volume in liquid paraffin hardly changes within 72 hours....

Embodiment 2

[0034] Add 6 grams of butyl linoleate (B) to the aqueous suspension containing 100 grams of nano-calcium carbonate, and react with high-speed stirring in a flask at room temperature for 0.5 hours. Cool to room temperature to obtain modified nano calcium carbonate B-CaCO 3 .

[0035] Add B-CaCO to 100 parts of PVC resin respectively 3 and U-CaCO 3 30 parts, 5 parts of rare earth calcium zinc stabilizer, kneaded evenly, kneaded and plasticized on a Φ160 double-roller open mill, the kneading temperature was 175°C, after the kneading was uniform, the heated hydraulic flat press was used to mold the sample. The molding temperature was 180°C. After cooling, the sample was cut with a universal sample making machine, and the mechanical properties were tested. The results are shown in Table 1.

[0036] sample

Tensile strength (MPa)

Impact strength (kJ / m 2 )

Bending strength (MPa)

Flexural modulus (MPa)

PVC / B-CaCO 3

PVC / U-CaCO 3

pvc

...

Embodiment 3

[0040] Add 1 gram of castor oil (C) to 100 grams of nano-calcium carbonate dry powder, and react with high-speed stirring in a flask at 100° C. for 5 hours. Cool to room temperature to obtain modified nano calcium carbonate C-CaCO 3 .

[0041] Prepare PVC / C-CaCO by the formula of embodiment 2 and process condition 3 The nanocomposites were measured and their mechanical properties are listed in Table 2.

[0042] sample

[0043] Table 2 shows that adding modified nano-calcium carbonate C-CaCO3 to PVC resin can greatly improve the impact strength and flexural modulus of the composite material with a small increase in tensile strength and flexural strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com