Hybridized fiber contg. high molecular material, carbon material and hydroxy apatite and its prepn. method

A technology of hydroxyapatite and polymer materials, which is applied in fiber processing, fiber chemical characteristics, filament/wire forming, etc., can solve the problem of not having a porous structure and can not meet the biological high performance requirements of porous scaffold composite materials, etc. problem, to achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

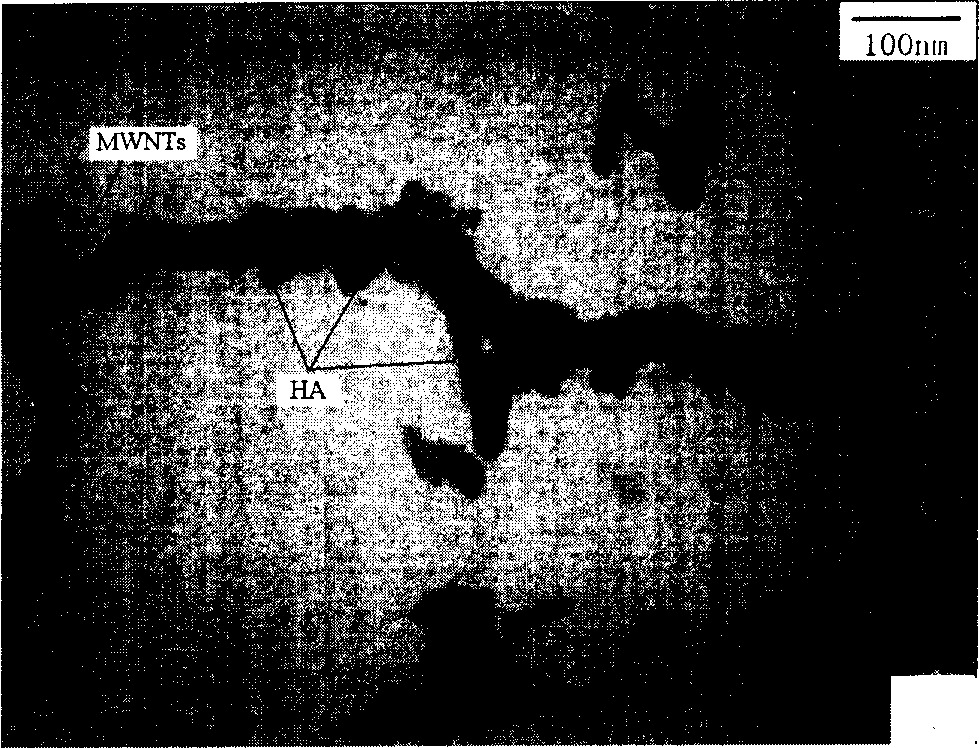

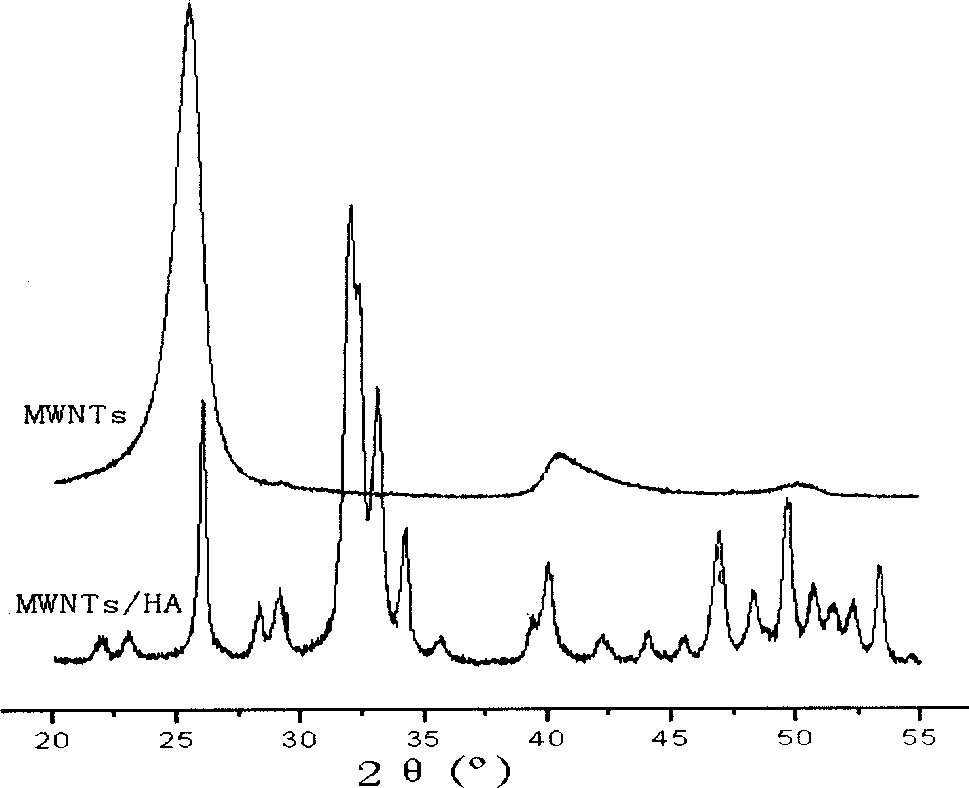

[0019] Embodiment 1: Preparation of carbon fiber / nanometer hydroxyapatite nanocomposite particles: Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 Dissolve in deionized water respectively to make a solution with a certain molar concentration, adjust the pH value to 12 and 9 with ammonia water, and the stoichiometric ratio of the reaction is Ca / P=1.67, which is consistent with the Ca / P in the natural bone of the human body; Quality is equivalent to the carbon nanotube (diameter is 20-40nm, produced by Shenzhen Nanometer Harbor Co., Ltd.) and Ca(NO 3 ) 2 4H 2 O solution was mixed, and ultrasonic pre-vibration was started for 10 minutes; the solution was put into the reactor and stirred, and ultrasonic oscillation was used as an auxiliary means, the temperature was about 25°C, and then (NH 4 ) 2 HPO 4 Liquid, drop rate 4.5ml / min, and maintain a pH value of about 10; from (NH 4 ) 2 HPO 4 After the addition of liquid drops is completed, the reaction mixture is taken out within 2...

Embodiment 2

[0020] Embodiment 2: Preparation of carbon fiber / hydroxyapatite nanocomposite particles: Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 Dissolve in deionized water respectively to form a solution with a certain molar concentration, adjust the pH value to 12 and 9 respectively with ammonia water, the stoichiometric ratio of the reaction is Ca / P=1.67, which is consistent with the Ca / P in the natural bone of the human body; Add carbon nanofibers with a mass equivalent to 5% of the mass fraction of calcium ions to Ca(NO 3 ) 2 4H 2 In the O solution, the temperature is 45°C, and the ultrasonic wave is pre-oscillated for 10 minutes; then the Ca(NO 3 ) 2 The solution was added dropwise (NH 4 ) 2 HPO 4 solution, the rate of addition is about 2.5ml / min, during the reaction, keep the pH value of the solution above 10, from (NH 4 ) 2 HPO 4 After the dropwise addition was completed, it was washed and dried at 120°C to obtain the in-situ-synthesized solution and continued to react fo...

Embodiment 3

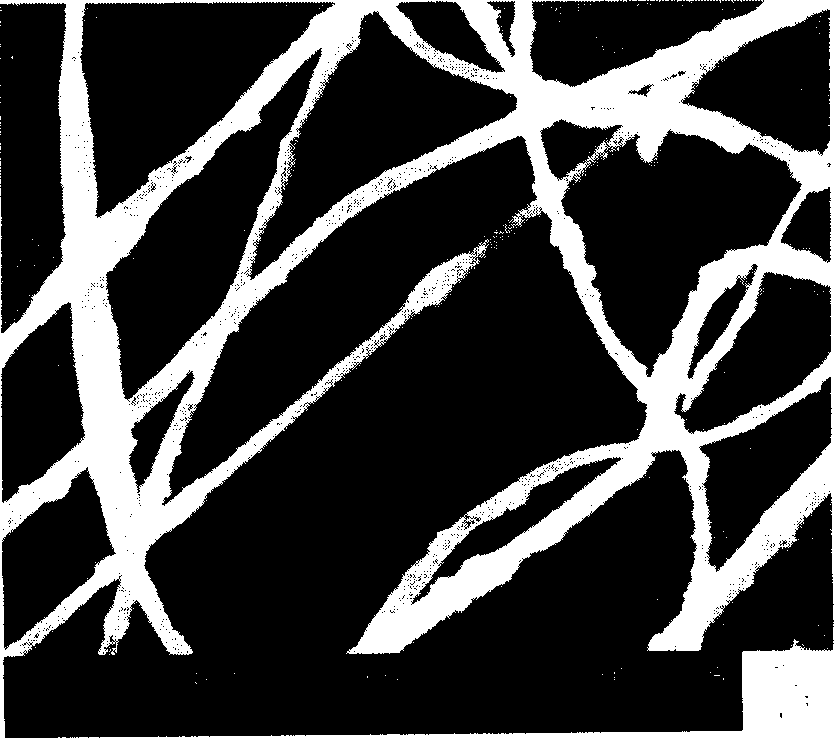

[0021] Example 3: 50 parts of carbon fiber / hydroxyapatite nanocomposite particles prepared in Example 1 were dispersed in 1,4-dioxane solvent under ultrasonic vibration, and 50 parts of polylactic acid-caprolactone copolymer / Dichloromethane solution is slowly added dropwise to the nano-carbon fiber / nano-hydroxyapatite / acetone dispersion system, and after the addition is completed, continue to ultrasonically oscillate for 0.5h to obtain PLA-CL / nano-carbon material / nano-hydroxyl with a concentration of 6%. Apatite electrospinning suspension, the mixed solution is prepared under the condition of static voltage of 22kV and receiving distance of 9cm to prepare PLA-CL / carbon fiber / hydroxyapatite hybrid fiber with a diameter of 1.5μm-2.0μm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com