Method for improving emission stability of high-temperature electrons of SiC field emission cathode materials

A field emission cathode, electron emission technology, applied in nanotechnology for materials and surface science, cold cathode manufacturing, discharge tube/lamp manufacturing, etc., to achieve the effect of excellent high temperature electron emission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

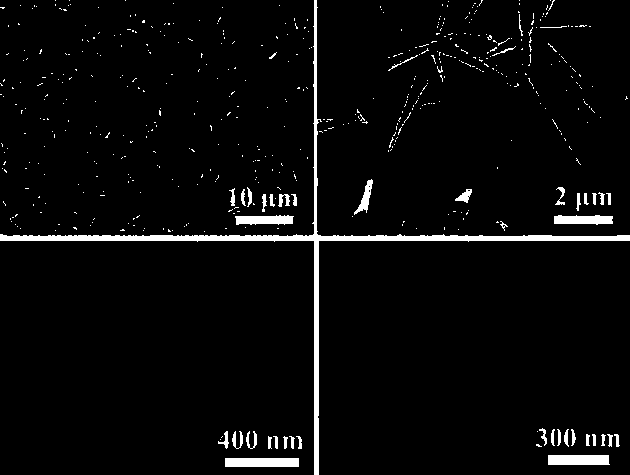

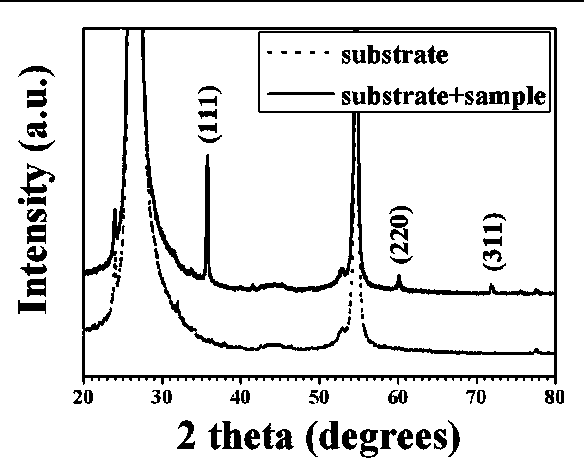

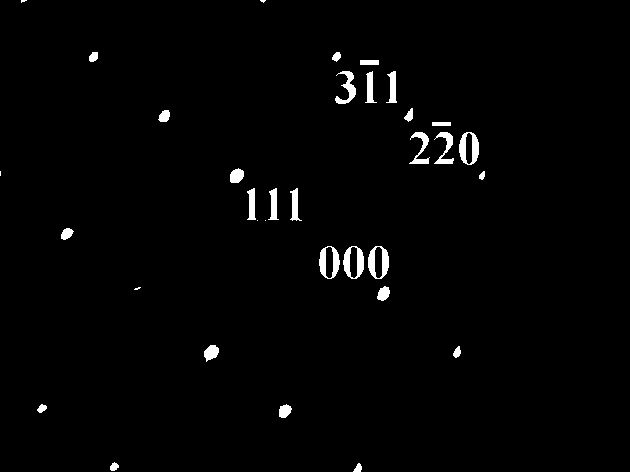

Image

Examples

Embodiment 1

[0032] The initial raw material is polysilaborazane (chemical composition: Si 0.64 BC 0.78 N 1.53 o 0.25 ), under the protection of an Ar atmosphere with a purity of 99.9%, at 260 ° C for 30 min for thermal crosslinking and curing. Put the solidified SiBCN solid into a nylon resin ball mill tank, and ball mill it into powder. Cut carbon paper 5x5 cm (length x width), in 0.05 mol / L Co(NO 3 ) 3 (Purity: 99%) soak in ethanol solution for 1 minute, take it out and put it in the air environment to dry naturally. Weigh 0.3 mg SiBCN powder, place it at the bottom of the graphite crucible, and place the impregnated carbon paper on the top of the graphite crucible, and place them together in a graphite resistance heating atmosphere sintering furnace. The atmosphere furnace is first evacuated to 10 -4 Pa, and then filled with high-purity Ar gas (purity 99.9%) until the pressure is one atmosphere (~0.11Mpa), and then the pressure is constant. Then the temperature was raised from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com