Structure of direct alcohol fuel cell membrane electrode aggregate and preparation method thereof

A fuel cell membrane and aggregate technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems that plague practical applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

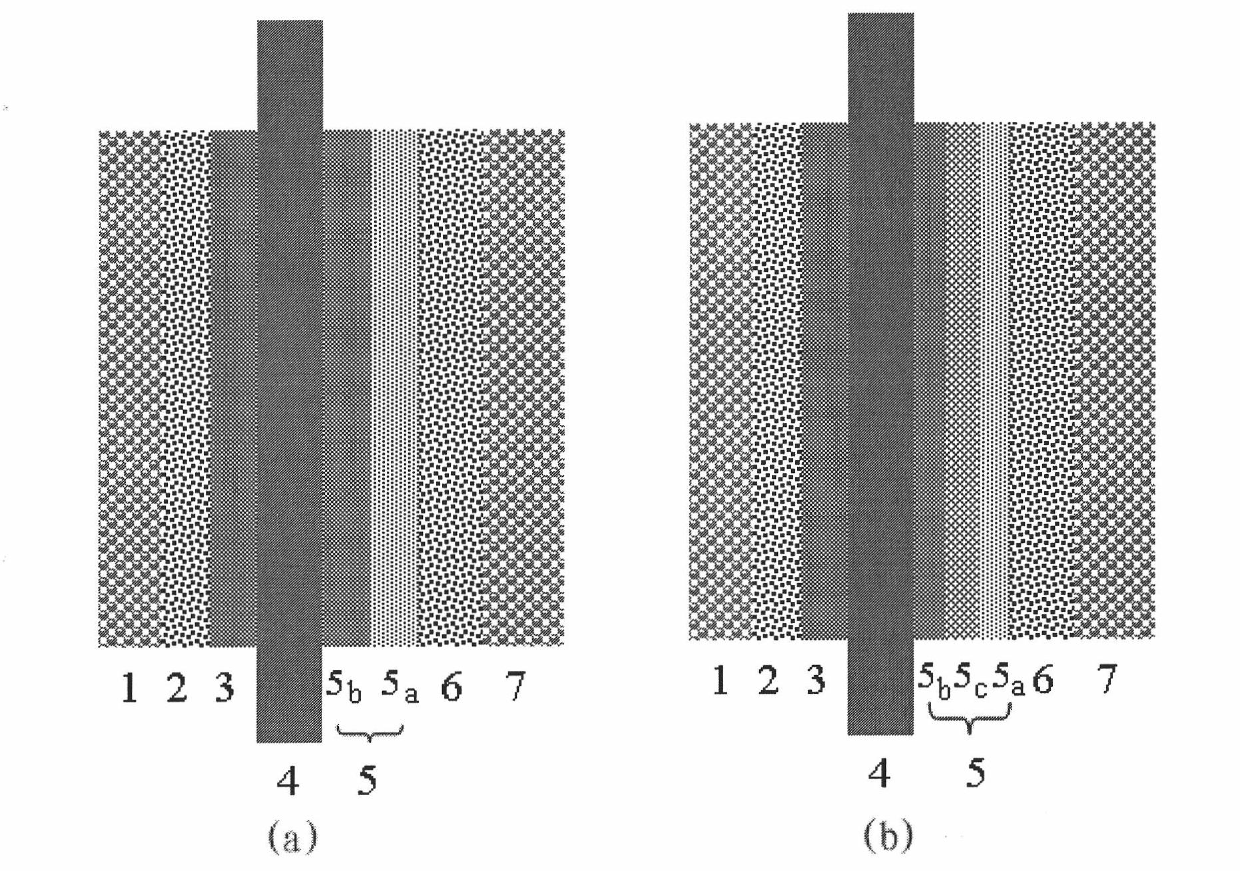

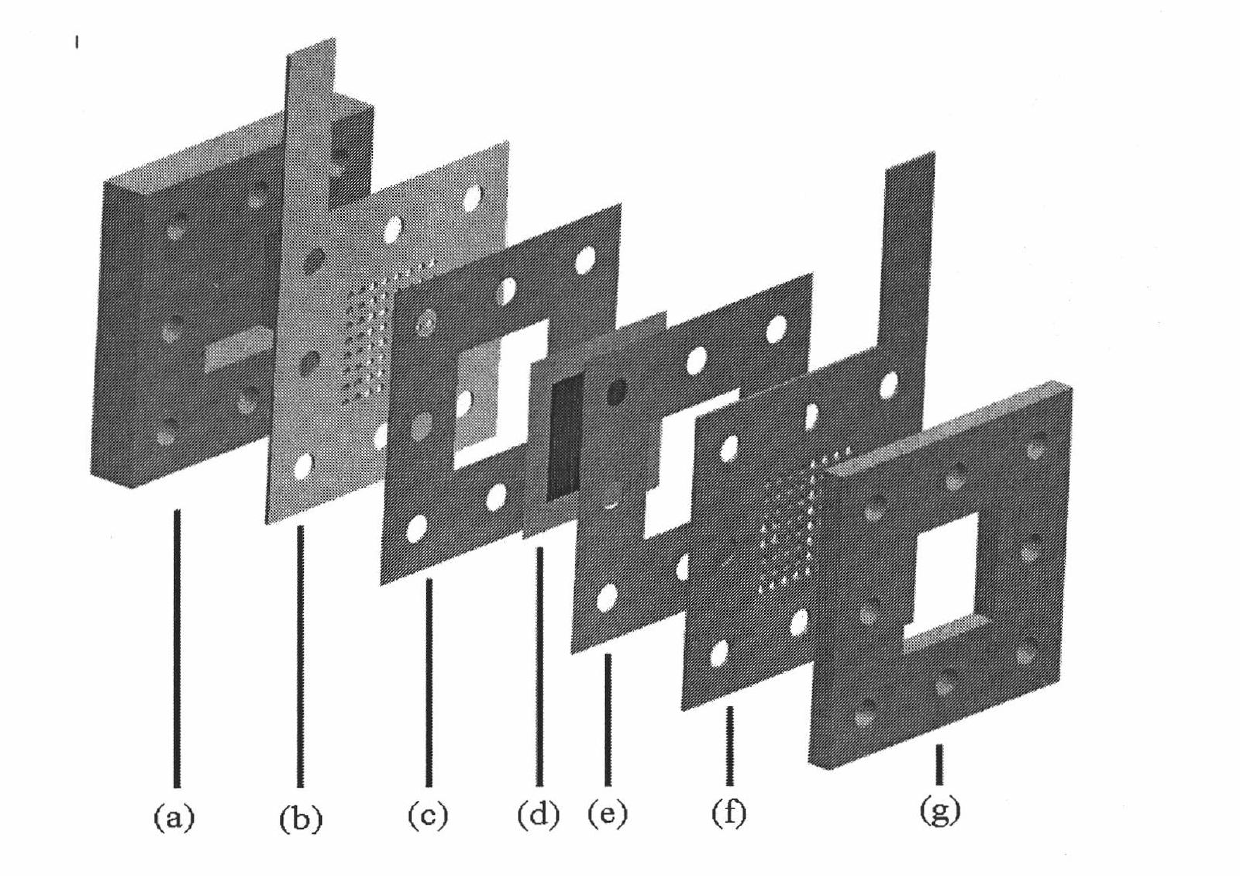

[0020] Embodiment 1 The preparation technology of the MEA of the double-layer catalytic layer cathode structure of the direct methanol fuel cell

[0021] 1. Weigh 20.0mg of Vulcan XC-72R and 36.5mg of PTFE emulsion with a mass percent concentration of 13.7% and disperse them in a mixed solution of 0.3mL of water and isopropanol (the volume ratio of isopropanol and water is 1:1), and ultrasonically Disperse for 3 hours to get a uniform carbon slurry.

[0022] 2. Take by weighing 20.0mg60wt.%Pt-Ru / C (Pt: Ru=2: 1) and 12.0mgPt-Ru black, add 50.0mg ultrapure water and all catalysts are wetted, then add 160.0mg mass percentage concentration to be 5% Nafion solution, and then add 0.4mL of water and isopropanol mixture (volume ratio of isopropanol and water is 1:1) as a dispersant, and control the temperature below 40°C for ultrasonic dispersion for 3 hours to obtain an anode catalyst ink. Weigh 20.0mg60wt.%Pt / C, add 60.0mg ultrapure water to wet the catalyst, add 50.0mg mass percen...

Embodiment 2

[0029] Example 2 Preparation Technology of MEA with Three-layer Catalytic Layer Cathode Structure of Direct Methanol Fuel Cell For the convenience of description, this embodiment takes the middle layer (C) as an example to form a three-layer catalytic layer cathode structure. If the middle layer (C) is two layers, it will constitute a four-layer catalytic layer cathode structure. Theoretically, the middle layer (C) can be multi-layered, but the components are distributed in a gradient, but considering the actual application and effect, three Layers are the most commonly used structure.

[0030] 1. Take by weighing 20.0mg Vulcan XC-72R and 36.5mg mass percent concentration and be that the PTFE emulsion of 13.7% is dispersed in the mixed solution of 0.3mL water and isopropanol (the volume ratio of isopropanol and water is 1: 1), A uniform carbon slurry can be obtained by ultrasonic dispersion for 3 hours.

[0031] 2. Weigh 20.0mg of 60wt.% Pt-Ru / C (Pt:Ru=2:1) and 12.0mg of Pt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com